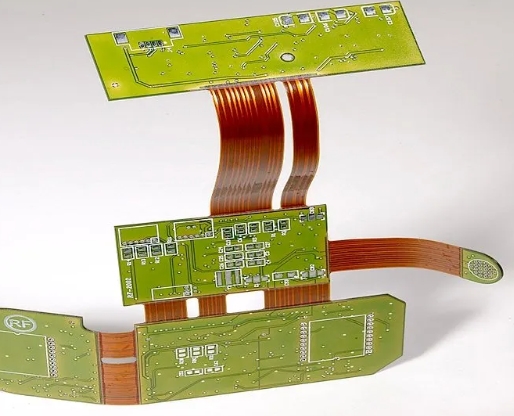

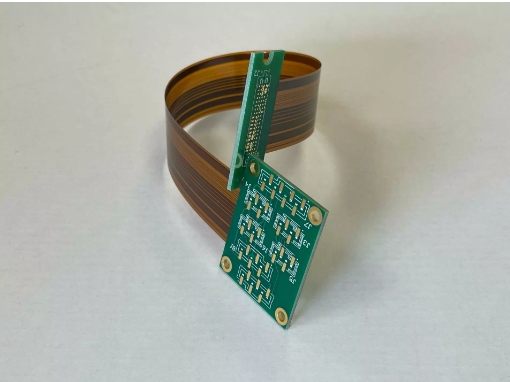

In the past decade, electronic devices have become increasingly thinner, smarter, and more compact. As the demand for miniaturization and efficiency grows, semi-rigid PCBs have emerged as a well-deserved trend. Their adaptability and versatility make them ideal for applications requiring effective space utilization and enhanced reliability. What is a Semi-Flexible PCB? A semi-flexible PCB is a type of printed...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

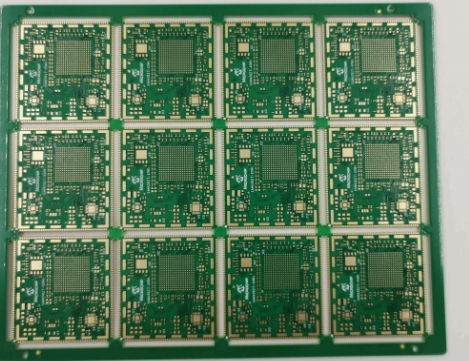

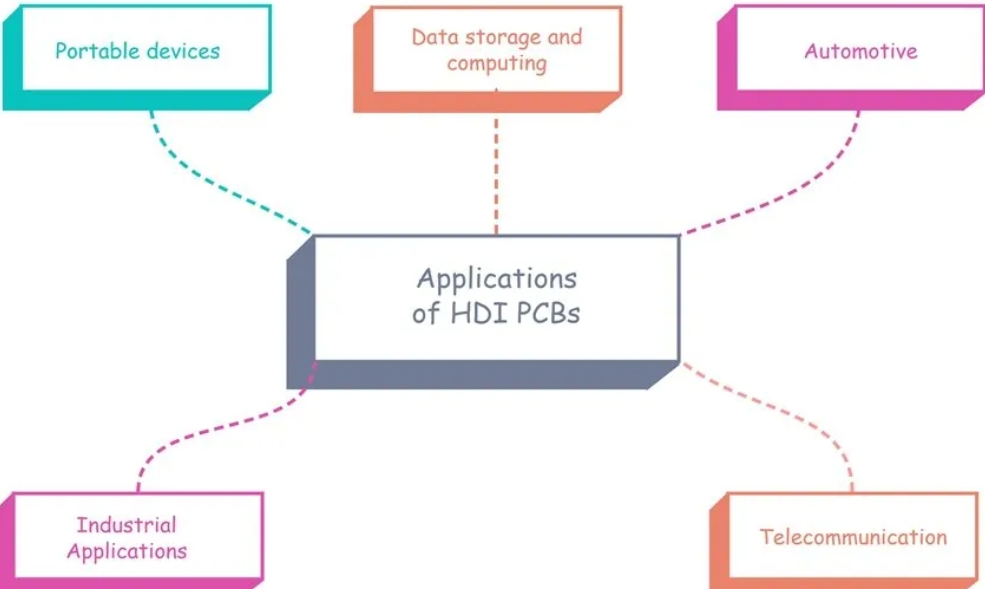

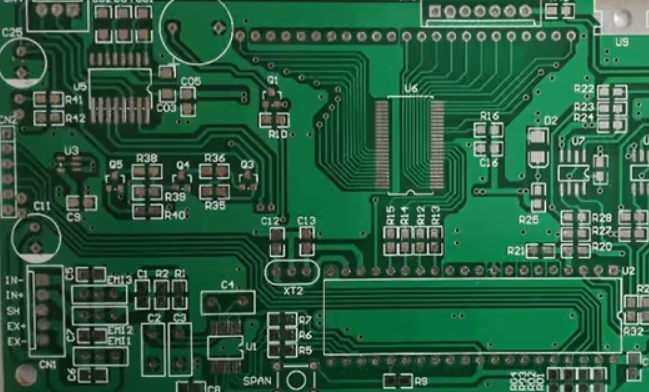

In today’s world, electronic products have become more complex than before to achieve better performance and thus transfer data faster than ever before. HDI (High Density Interconnect) is a technology used in PCBs to achieve miniaturization of circuit boards with higher component density. Therefore, HDI PCB design considerations are particularly important in HDI PCB manufacturing. In this article, let’s...

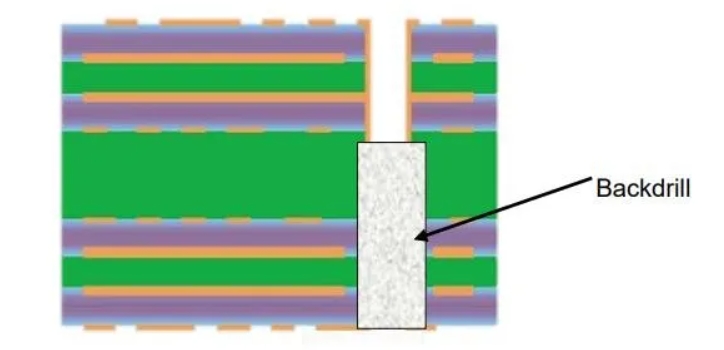

What is Backdrill? Back drilling is a method to remove the via stub from the specific layer of multilayer PCB. Via stub is a non-functional portion of a plated through hole or via barrel which can cause unwanted reflection leading to signal distortion and lower performance. It is recommended that the diameter of the back drill...

In the evolving world of electronics, where everything matters including the size, shape and performance of a device, PCBs help in the development and implementation of complex yet advanced technologies in electronic devices day by day. In the present world, especially in the current technological era, devices are becoming more compact and advanced. For implementing...

Technological advancement demands that electronic devices be more versatile and smarter. From slim smartphones to sophisticated medical devices, PCBs are becoming the heart of such advancement, and demand for more reliable technological advancements is increasing daily, which requires more complex PCBs i-e Rigid-Flex PCBs. This comprehensive guide covers almost every aspect of one of the PCB...

A Rigid-Flex PCB is a hybrid circuit board combining elements of both flexible circuit boards and rigid circuit boards, with an end result of a board that is able to be folded or continuously flexed and is normally formed into a flexed shape or curve during the manufacturing process. The flexible layers of a Rigid-Flex PCB are buried within the board and...

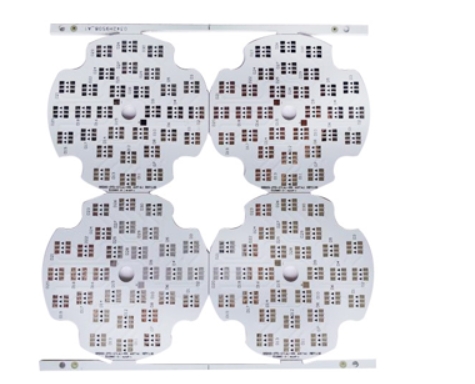

In PCB fabrication, every material is important. Aluminum PCB core circuit boards (aluminum PCBs) have different characteristics than circuit boards without metal substrates (standard PCBs). These two popular circuit board types power a wide range of commercial and consumer electronics. Is an aluminum PCB or a standard PCB the best fit for your project? The answer depends on...

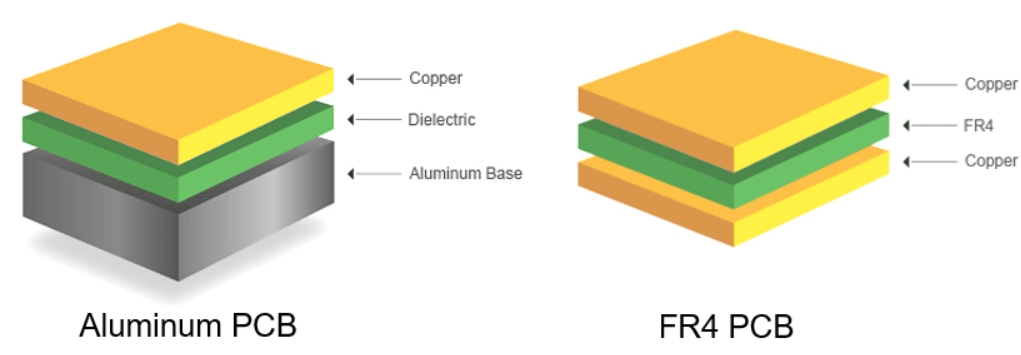

With the continuous development of electronic technology, the application of PCBs has become increasingly widespread. PCBs are integral components of electronic devices, playing crucial roles in various applications. Among them, Aluminum PCB and FR4 PCB (Glass Fiber Reinforced Epoxy Resin PCB) are two common types of PCBs with significant differences in terms of materials, performance, and applications....

Aluminum PCB vs. FR4 PCB: Cost, Materials, and Difference Nature of Material: If you are looking for a metal core material, Aluminum can be the best choice. Its main layer consists of an aluminum core infused with fiber glass. The metal clad contains a thermal layer for dissipating the generated heat energy to protect the...

After years of development, CB has evolved from a general circuit board for placing components to a circuit board with complex components. As a PCB designer or manufacturer, you are constantly challenged with how to achieve better results. You want to provide new solutions or breakthroughs to problems. In some cases, these problems may require...