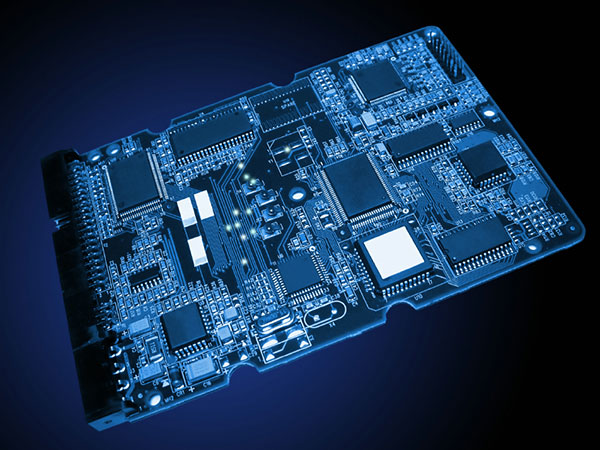

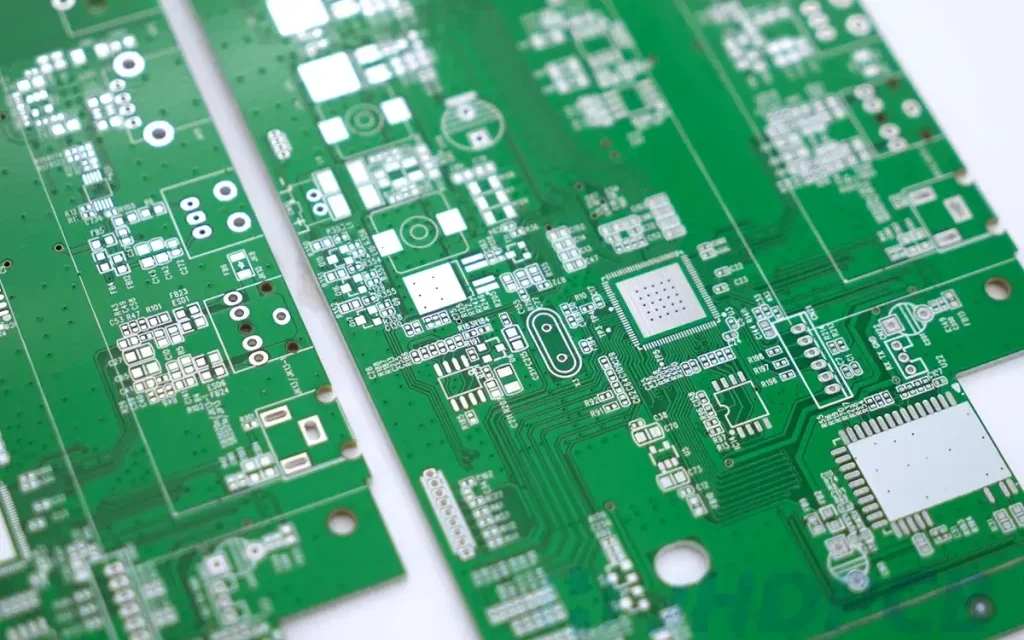

Introduction: Why PCB Prototype Engineering Defines Modern Electronics A PCB Prototype is no longer just a pre-production sample—it is the central engineering stage that determines product performance, manufacturability, reliability, and cost.In advanced electronics such as 5G, IoT, robotics, automotive, aerospace, AI edge computing, and industrial automation, a well-engineered PCB Prototype ensures signal integrity, thermal stability,...

HomeTag

PCB manufacturing - KKPCB

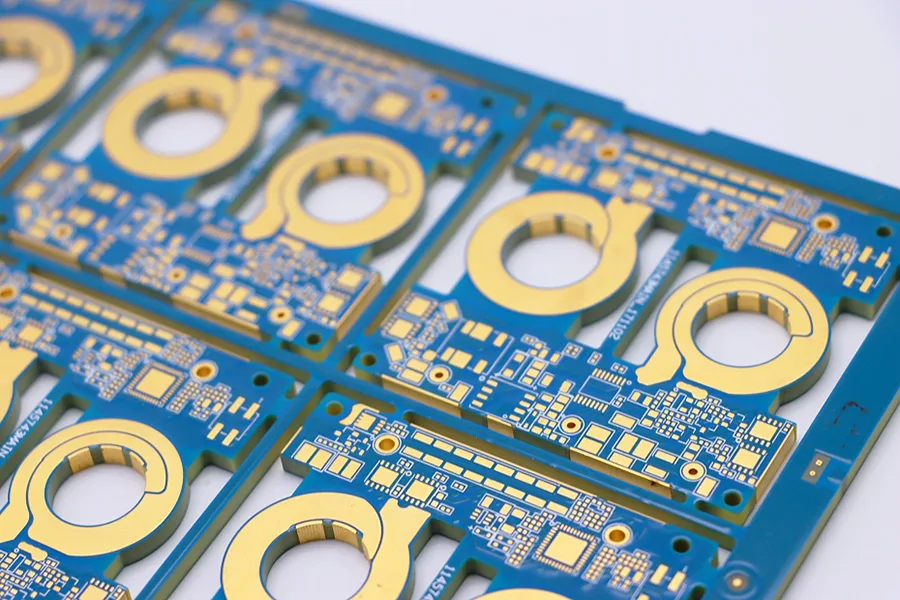

Modern wireless systems—from 5G radio units and phased-array antenna modules to automotive radar and satellite communication terminals—demand PCBs that deliver high RF power handling, exceptional phase stability, and ultra-low loss. As antenna modules continue to shrink while operating at higher frequencies, selecting the correct laminate becomes a mission-critical design decision. Among all mid-frequency RF substrates,...

Heavy Copper PCBs: High-Current Solutions for Power Electronics As electronic systems evolve toward higher power density, stronger reliability requirements, and increasingly harsh operating environments, Heavy Copper PCBs have become indispensable across power electronics, automotive systems, industrial control, and energy infrastructure. Unlike standard PCBs—typically manufactured with 1oz–3oz copper—a Heavy Copper PCB is defined as any PCB...

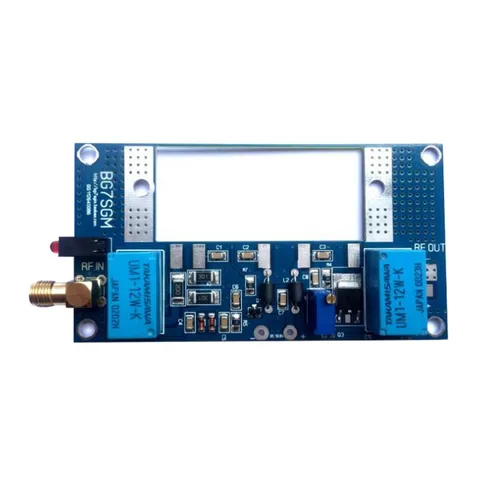

Essential RF Amplifier Knowledge for Modern PCB Manufacturers | KKPCB As wireless communication, IoT connectivity, radar sensing, and high-speed data links continue to evolve, RF amplifiers have become one of the most critical building blocks in modern electronics. For PCB manufacturers, understanding how RF amplifiers work—and how PCB design impacts their performance—is essential to delivering...

Megtron 6 is a premium high-speed, low-loss PCB laminate developed by Panasonic, designed specifically for next-generation high-frequency and high-data-rate systems. Positioned between standard FR-4 and PTFE-based microwave materials, Megtron 6 delivers exceptionally low transmission loss, stable dielectric performance, and robust thermal reliability—making it a preferred choice in telecom, networking, data-center, computing, and RF applications. By...

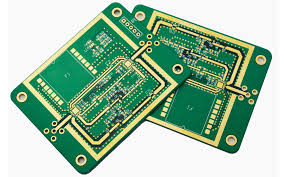

Single Layer PCBs: A Comprehensive and Technical Guide Introduction Single-layer printed circuit boards (PCBs)—often referred to as single-sided or 1-layer PCBs—represent the most fundamental yet enduring form of PCB technology. Despite the fast-growing adoption of multilayer, HDI, and advanced substrate solutions, single-layer boards continue to dominate large segments of consumer electronics, industrial instrumentation, IoT nodes,...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

ENIG PCB Surface Finish: Benefits, Process, and Applications Explained

What Is ENIG PCB Surface Finish? What Is ENIG in PCB Manufacturing? ENIG (Electroless Nickel Immersion Gold) is one of the most widely used and highly reliable PCB surface finishes in the electronics industry. As a chemical deposition process, ENIG forms a two-layer metallic coating—a nickel barrier layer followed by a thin immersion gold layer—without...

Applications of Factory Automation in PCB Manufacturing As electronic devices become more compact, powerful, and multifunctional, printed circuit boards (PCBs) must meet increasingly complex performance and reliability requirements. To support this evolution, factory automation has become a fundamental pillar of modern PCB manufacturing. Automated systems not only accelerate production but also improve precision, ensure repeatability,...

Introduction to Aluminum Oxide (Al₂O₃) Ceramic PCBs In the field of printed circuit board (PCB) manufacturing, the choice of substrate material plays an essential role in determining the product’s performance, reliability, and heat dissipation capability. Ceramic PCBs—particularly those using Aluminum Oxide (Al₂O₃)—have become increasingly popular due to their outstanding thermal and electrical properties. This article...

Why PCB Pad Soldering Process Matters In PCB manufacturing, the pad surface finish or soldering process directly affects component solderability, electrical performance, and long-term reliability.Different processes offer varying degrees of oxidation resistance, flatness, and cost efficiency, making proper selection essential for every PCB design project. This article categorizes and compares the most common PCB pad...