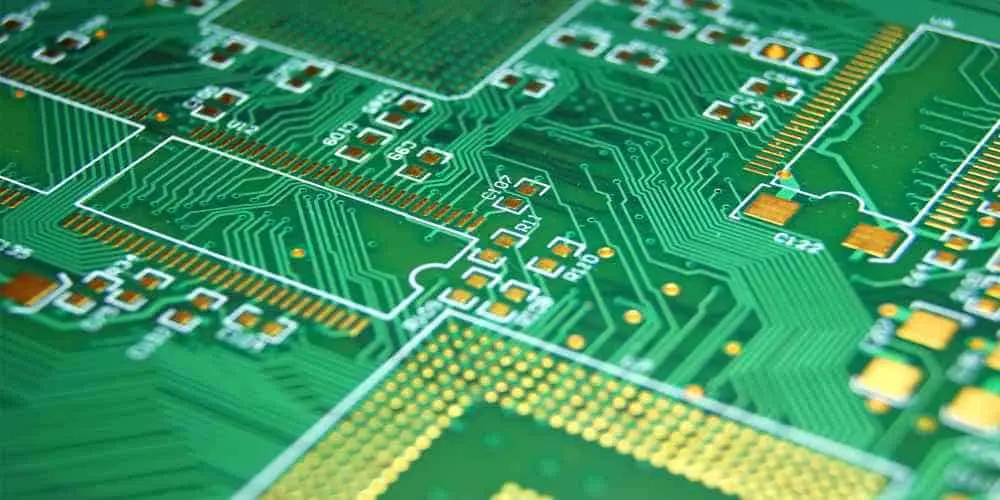

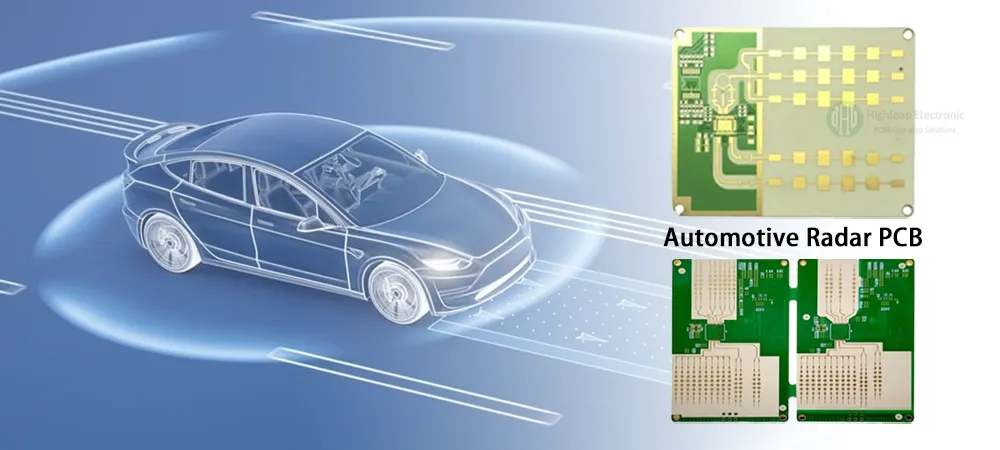

ADAS PCB Layout Guidelines for Automotive Radar Systems In the rapidly advancing world of automotive technology, Advanced Driver Assistance Systems (ADAS) are revolutionizing how we drive, enhancing safety and intelligence in vehicles. At the heart of many ADAS features lies the automotive radar system, which relies on precise and effective printed circuit board (PCB) design...

HomeTag

Signal Integrity - KKPCB

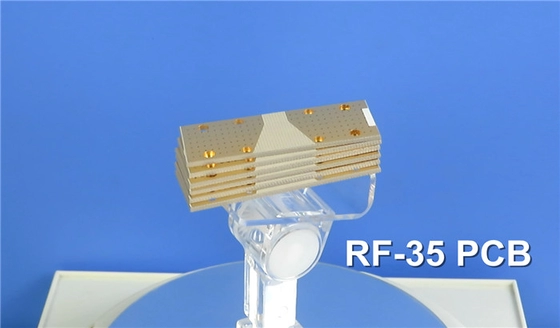

1. Introduction In advanced RF and microwave test systems, where signal accuracy defines measurement integrity, the substrate material directly determines consistency. The RF-35 PCB—a low-loss laminate with optimized dielectric uniformity—has become a preferred platform for network analyzers, calibration modules, and power sensors operating between 20 GHz to 50 GHz. KKPCB’s engineering framework addresses key...

Introduction As electronic systems continue to evolve toward higher frequencies and faster data rates, the need for advanced laminate materials becomes increasingly critical. Among the top performers in RF and microwave PCB substrates, Taconic RF-35 has gained industry-wide recognition for its outstanding signal integrity, thermal stability, and material uniformity.With a dielectric constant (Dk) of 3.5,...

Introduction With the rapid advancement of modern technology, high-frequency electronic systems such as RF, microwave, and radar equipment are increasingly prevalent. At the core of these systems lies the Printed Circuit Board (PCB) — the foundation upon which signal integrity and overall device performance depend. Among the materials used for PCB fabrication, Teflon (PTFE) stands...

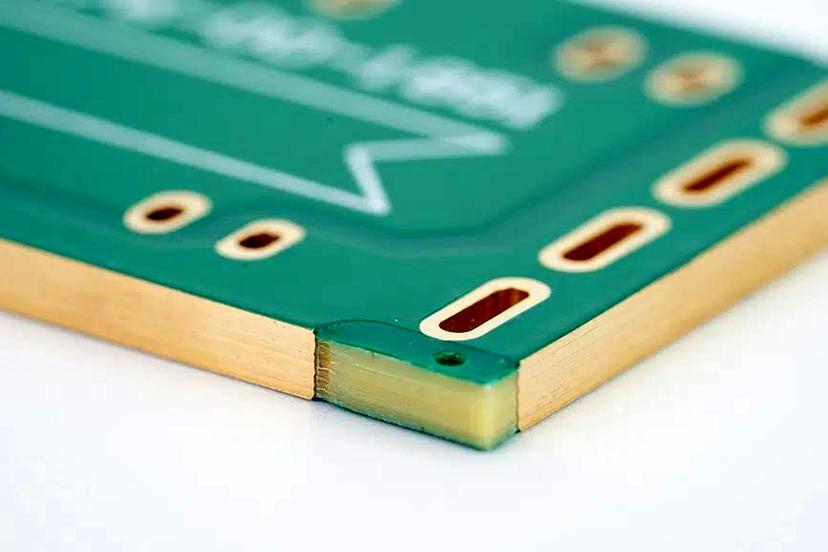

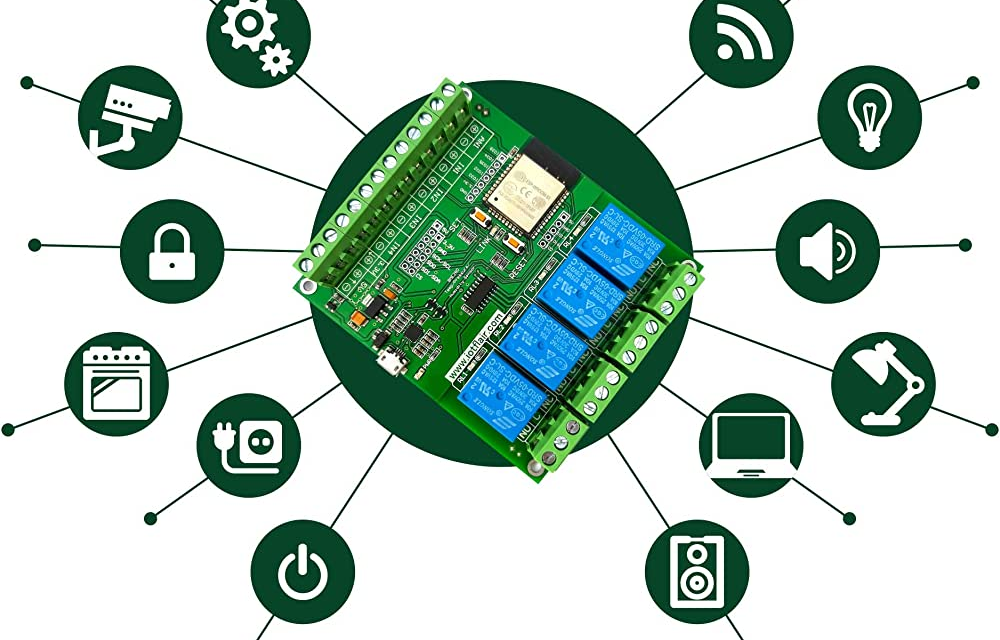

PCBs for Industrial Automation: The Backbone of Modern Control Systems In the fast-evolving world of industrial automation, Printed Circuit Boards (PCBs) are the unsung heroes that power the technology behind every automated machine, robot, and control system. From factory floors to advanced robotics, choosing the right PCB is crucial to the success of your automation...

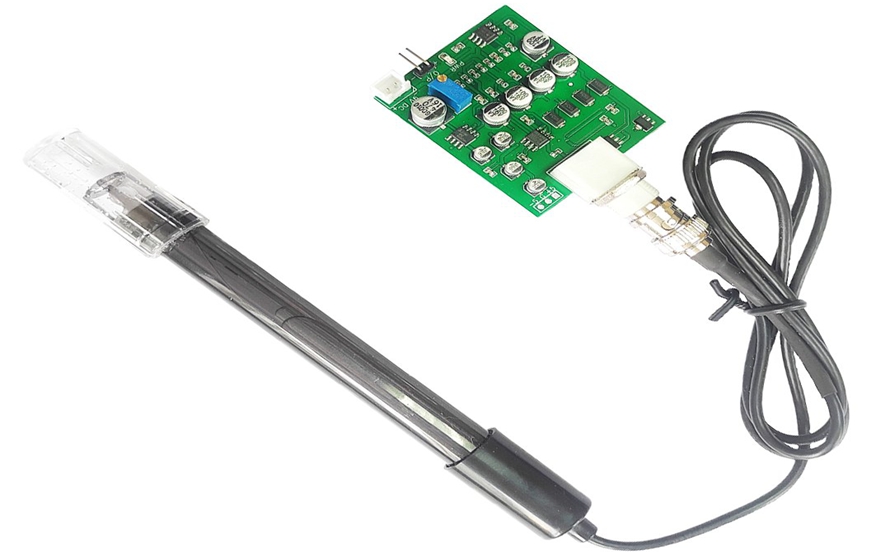

Engineering Precision in Automotive Sensor Testing and Calibration In modern automotive systems, sensors form the nervous system of intelligent vehicles—collecting real-time data, interpreting environmental signals, and transmitting them to the Electronic Control Unit (ECU). Every decision, from adaptive cruise control to emergency braking, depends on sensor precision and reliability.At KKPCB, we engineer the foundation of...

Mastering High-Speed PCB Test Point Design: Precision, Performance, and Signal Integrity In high-speed printed circuit board (PCB) design, test point placement is far more than a routine step—it’s a science of balance. The miniature metal pads scattered across a PCB may look simple, but their position, size, and electrical behavior can determine whether a product...

Signal Integrity and Cavity Resonance Control in Duroid 6010 PCB Substrates for RF Front-End Modules

Why Cavity Resonance Is the Hidden Enemy in High-Dk RF Boards In high-frequency RF front-end modules—especially those operating beyond 20 GHz—engineers often encounter unexpected resonance spikes, gain ripple, and phase drift despite ideal simulations. The culprit is frequently cavity resonance—localized standing waves caused by dielectric thickness, copper enclosure geometry, or high-Dk material behavior. ...

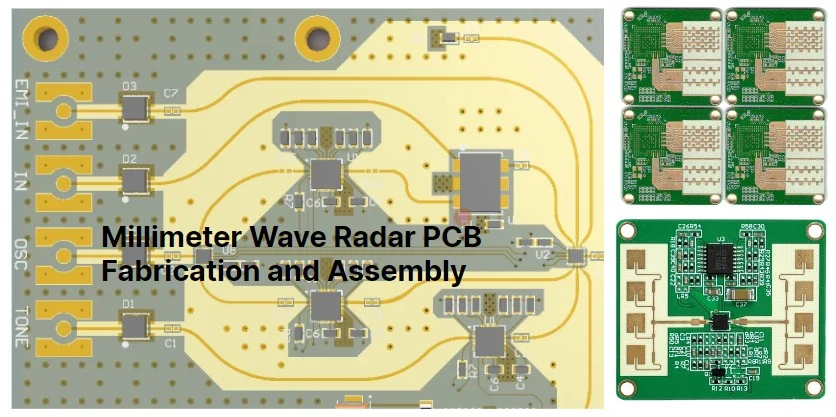

Enhancing RF Stability and Phase Accuracy Through KKPCB’s Precision Manufacturing and Dielectric Control Framework From Material Selection to Radar System Precision In modern 60 GHz radar sensor modules, used in advanced driver-assistance systems (ADAS), industrial robotics, and short-range imaging, signal integrity and impedance control directly determine detection accuracy and angular resolution.Even minor inconsistencies in...

Achieving High-Frequency Reliability and Efficient Heat Dissipation Through KKPCB’s Hybrid Lamination Platform From Material Performance to System-Level Efficiency In industrial mmWave transceiver modules operating from 28 to 81 GHz, engineers face a dual challenge: maintaining signal integrity across multilayer stackups while managing localized power density and heat accumulation.Traditional FR-4 or mid-grade PTFE composites...