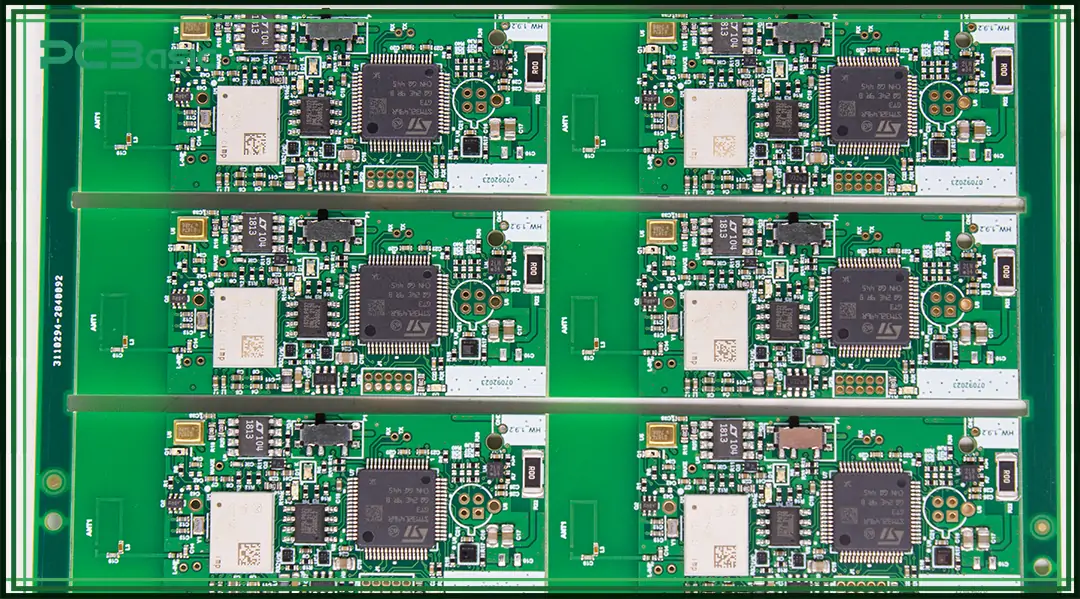

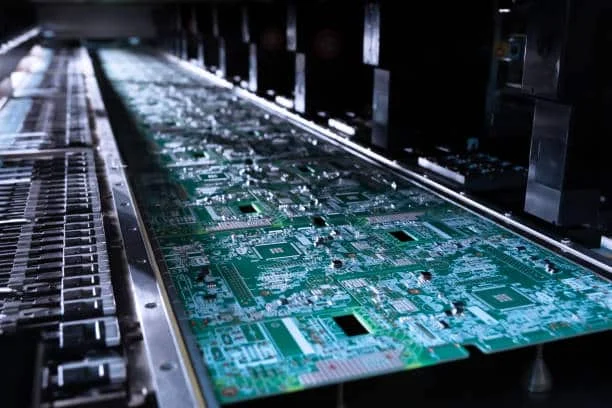

In today’s fast-paced electronics industry, rapid product validation and frequent design iterations are essential.small batch PCBmanufacturing provides an ideal solution for startups, R&D teams, and engineering groups that require high-quality PCBs without committing to large production volumes. This article explores what small batch PCB manufacturing is, why it matters, and how it supports efficient product...

HomeTag

PCB manufacturing - KKPCB

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Factory Direct: Cost-Effective and Reliable PCB Manufacturing from the Source

In today’s global electronics supply chain, many companies are choosing PCB factory direct sourcing to reduce costs, improve communication, and ensure consistent manufacturing quality. Working directly with a PCB factory eliminates unnecessary intermediaries and gives customers greater control over pricing, lead time, and production transparency. This article explains what PCB factory direct means, why it...

Submitting a clear and complete PCB price request is the first step toward accurate pricing, short lead times, and smooth production. Whether you are sourcing prototype PCBs, small batch orders, or mass production, providing the right information helps PCB manufacturers evaluate cost, manufacturability, and delivery schedules efficiently. This article outlines the essential details required for...

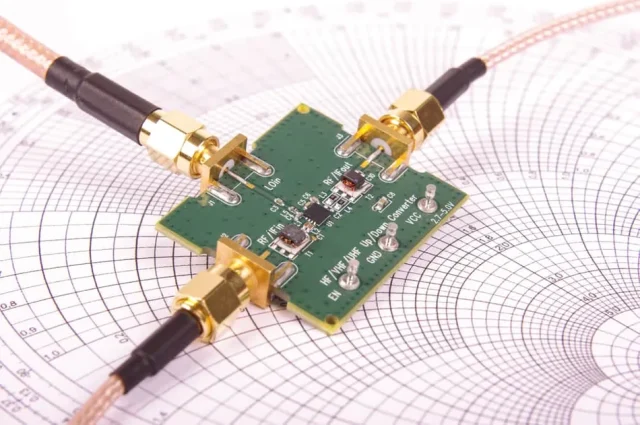

As wireless communication, radar systems, and high-speed data transmission continue to advance, high frequency PCBs have become a critical foundation for modern RF front-end modules. Selecting the right materials and stack-up structures—such as Rogers PCBs, PTFE PCBs, and hybrid PCB stackups—is essential to achieving low loss, stable impedance, and reliable RF performance. This article explains...

In today’s highly competitive electronics market, speed and reliability are critical during the product development stage. High-reliability small batch PCB manufacturing enables engineers to accelerate product validation, shorten engineering iteration cycles, and reduce development risk before mass production. This article explains how small batch PCB manufacturing supports rapid prototyping, design verification, and engineering optimization, helping...

PCB Turnkey Services: A Complete One-Stop Solution for PCB Manufacturing and Assembly In today’s fast-paced electronics industry, reducing supply chain complexity and accelerating time to market are critical for success. PCB Turnkey services provide a complete, one-stop solution that covers every stage of electronics production—from PCB fabrication and component sourcing to assembly, testing, and final...

As electronic devices continue to evolve toward higher speeds, greater bandwidth, and higher operating frequencies, impedance control on PCBs has become a critical requirement rather than an optional design consideration. In high-speed PCB, RF PCB, and high-frequency circuit design, improper impedance control can lead to signal degradation, EMI issues, and overall system instability. This article...

Key Manufacturing Factors That Affect Controlled Impedance PCB Accuracy In today’s high-speed electronics market, Controlled Impedance PCB manufacturing has become a fundamental requirement for ensuring excellent signal integrity and stable electrical performance. As operating frequencies and data transmission speeds continue to rise, even minor impedance deviations in a controlled impedance PCB can result in signal...

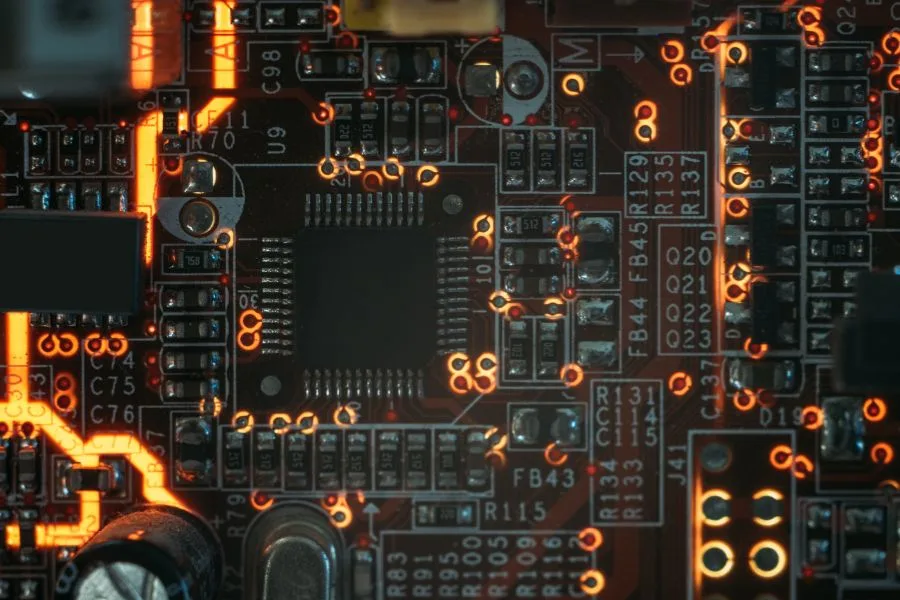

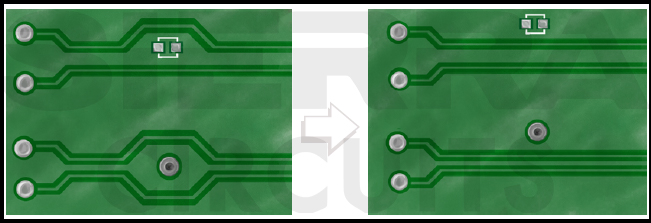

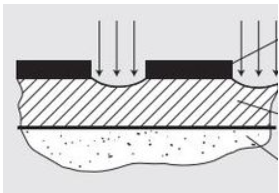

Control of Conductor Etching Process in Printed Circuit Boards Copper etching is one of the most critical steps in printed circuit board (PCB) manufacturing, as it directly determines the accuracy and reliability of conductive circuit patterns. The term “printed circuit board” originates from this process, since etching is the final stage of photolithography used to...

A Double Layer HF PCB may appear structurally simple, yet in high-frequency engineering it provides a remarkably efficient platform for low-loss propagation, stable impedance, and predictable electromagnetic behavior. When RF designers need high-frequency stability without the cost or stackup escalation of multilayer PCBs, a Double Layer HF PCB offers the ideal balance between manufacturability and...