ODM PCB: End-to-End Custom PCB Solutions for Innovative Electronics In today’s fast-evolving electronics market, companies increasingly rely on ODM PCBs (Original Design Manufacturer PCBs) to accelerate product development, reduce design complexity, and streamline manufacturing. An ODM PCB service allows engineers to outsource not just fabrication, but also design, prototyping, and assembly, providing a turnkey solution...

HomeTag

PCB assembly - KKPCB

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Factory Direct: Cost-Effective and Reliable PCB Manufacturing from the Source

In today’s global electronics supply chain, many companies are choosing PCB factory direct sourcing to reduce costs, improve communication, and ensure consistent manufacturing quality. Working directly with a PCB factory eliminates unnecessary intermediaries and gives customers greater control over pricing, lead time, and production transparency. This article explains what PCB factory direct means, why it...

PCB Turnkey Services: A Complete One-Stop Solution for PCB Manufacturing and Assembly In today’s fast-paced electronics industry, reducing supply chain complexity and accelerating time to market are critical for success. PCB Turnkey services provide a complete, one-stop solution that covers every stage of electronics production—from PCB fabrication and component sourcing to assembly, testing, and final...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

ENIG PCB Surface Finish: Benefits, Process, and Applications Explained

What Is ENIG PCB Surface Finish? What Is ENIG in PCB Manufacturing? ENIG (Electroless Nickel Immersion Gold) is one of the most widely used and highly reliable PCB surface finishes in the electronics industry. As a chemical deposition process, ENIG forms a two-layer metallic coating—a nickel barrier layer followed by a thin immersion gold layer—without...

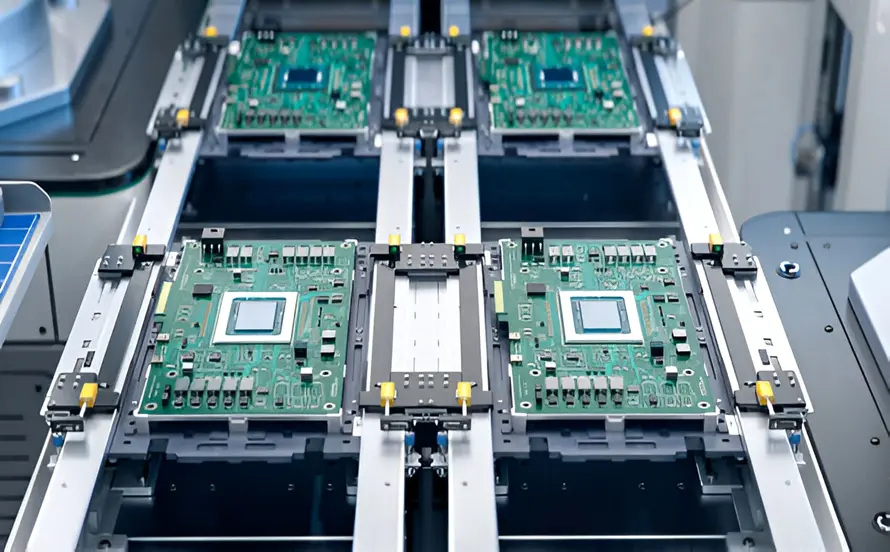

Industrial IoT PCB Innovation: The Core of Intelligent Manufacturing 1. Introduction: The Intelligent Backbone of Industry 4.0 The Industrial Internet of Things (IIoT) represents the convergence of machines, sensors, and intelligent electronics into a unified, connected ecosystem. By enabling seamless communication between devices and systems, IIoT is transforming traditional manufacturing into smart, self-optimizing environments. At...

Ensuring PCB Reliability Through Burn-in Testing — How KKPCB Guarantees Long-Term Performance In high-performance electronics, reliability isn’t a luxury — it’s a requirement. At KKPCB, every printed circuit board that leaves our production line is expected to perform consistently under demanding real-world conditions. One of the most critical steps in achieving that standard is our...

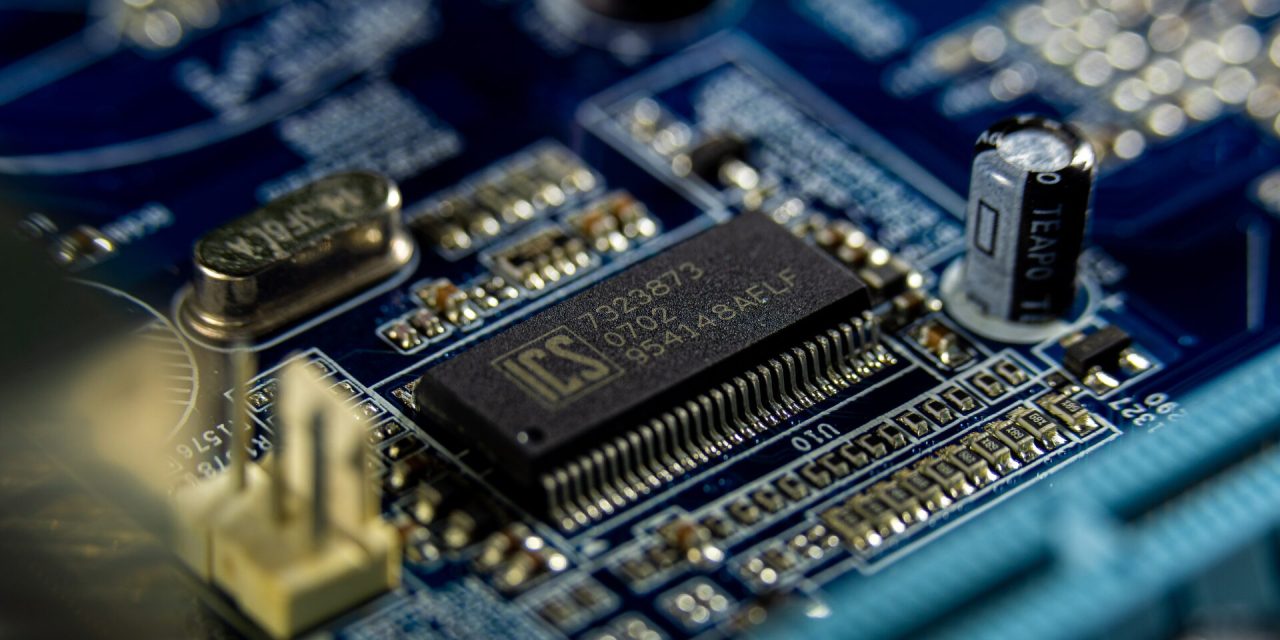

PCB design translates electrical schematics into a functional product, and its quality directly impacts production efficiency and product reliability. For beginners, mastering PCB layout can be challenging despite familiarity with design software, and common issues often arise. Here, seasoned engineers from KKPCB share their PCB layout insights to help avoid these pitfalls and inspire best practices. Component Placement...

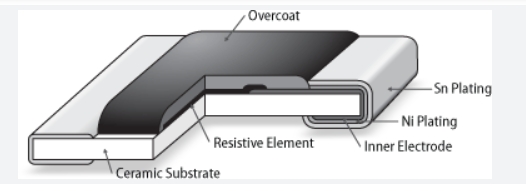

Thin and Thick Film Resistors are the most common types in the market. They are characterized by a resistive layer on a ceramic base. Although their appearance might be very similar, their properties and manufacturing process are very different. The naming originates form the different layer thicknesses. Thin film has a thickness in the order of 0.1μm...

SMT, the short form of Surface Mount Technology, a type of PCB (Printed Circuit Board) assembly technology, refers to the technology of getting components directly soldered onto the surface of PCB to replace THT (Through-Hole Technology) that has to make use of drilling holes. This article will discuss the essential elements of SMT assembly so that readers are able...

Surface Mount Technology (SMT) board assembly is a critical and widely used process in modern PCB manufacturing. This process involves placing and soldering electronic components directly onto the surface of PCB pads. Alongside Plated Through-Hole (PTH) assembly, it is one of the two primary PCB assembly methods. SMT assembly is highly efficient and accurate, making it...