Small Batch ATE PCB: Rapid, Reliable PCB Solutions for Semiconductor Test

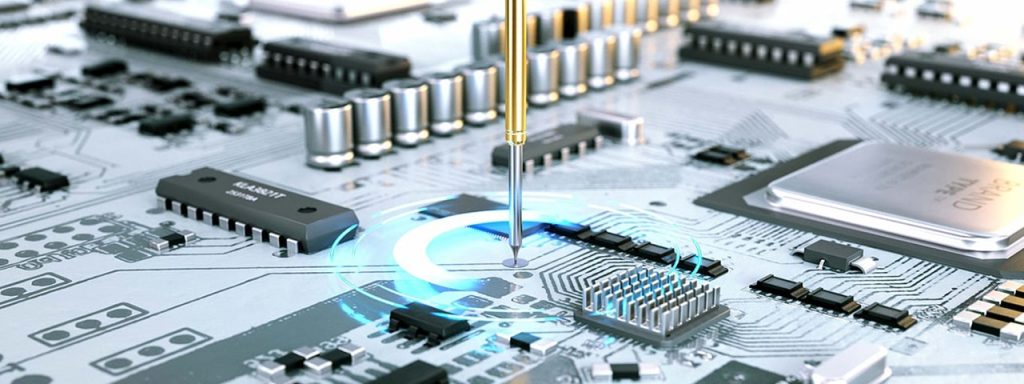

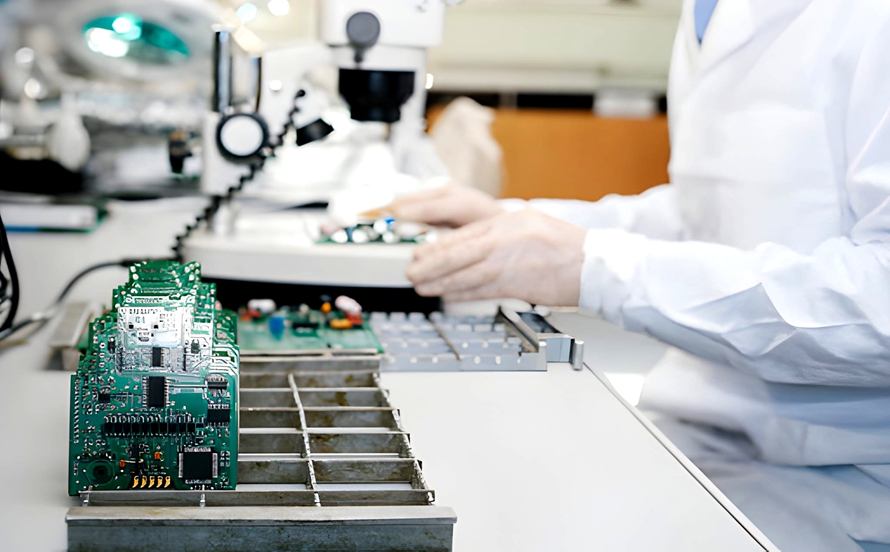

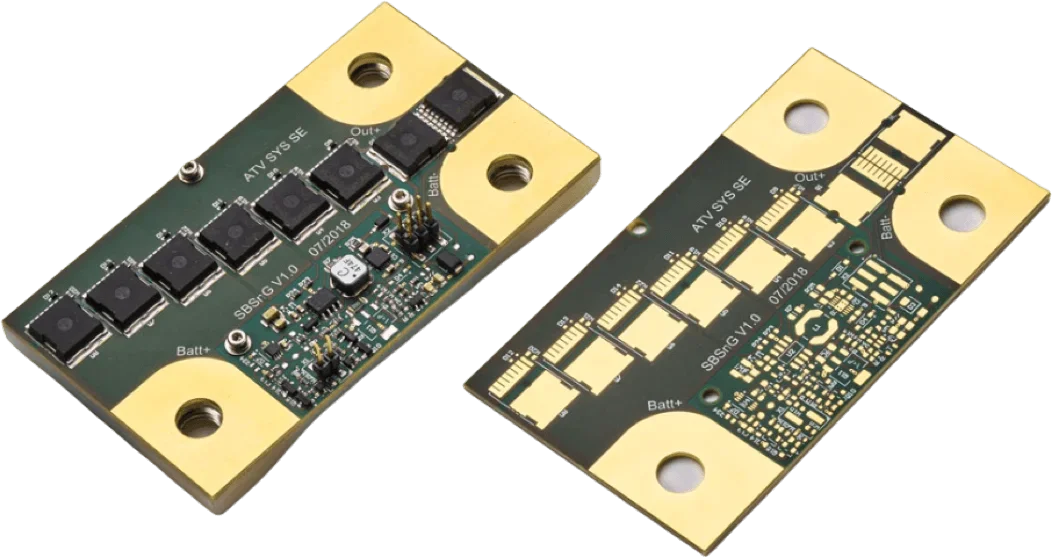

In semiconductor testing, time-to-market and development efficiency are critical. Small batch ATE PCBs provide a flexible solution for engineers who need rapid prototyping, functional validation, and low-volume production without compromising performance or reliability. These PCBs are designed to handle high-density connections, controlled impedance, and stable signal integrity, making them essential for modern automated test equipment...