When designing printed circuit boards (PCBs), a well-structured approach and attention to detail are essential to ensure functionality and avoid potential design errors. Here are some key PCB design tips based on practical experience: 1. Pay Attention to Pin Definitions and Package Names in the Schematic Library When creating the schematic library, ensure that each schematic pin corresponds correctly...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 5 of 75

PCB design translates electrical schematics into a functional product, and its quality directly impacts production efficiency and product reliability. For beginners, mastering PCB layout can be challenging despite familiarity with design software, and common issues often arise. Here, seasoned engineers from KKPCB share their PCB layout insights to help avoid these pitfalls and inspire best practices. Component Placement...

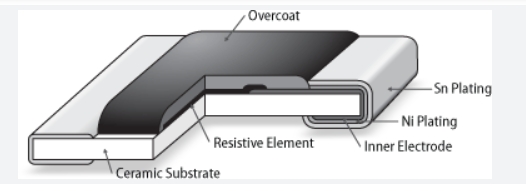

Thin and Thick Film Resistors are the most common types in the market. They are characterized by a resistive layer on a ceramic base. Although their appearance might be very similar, their properties and manufacturing process are very different. The naming originates form the different layer thicknesses. Thin film has a thickness in the order of 0.1μm...

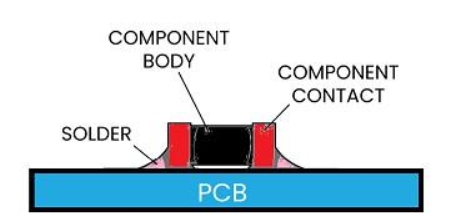

SMT, the short form of Surface Mount Technology, a type of PCB (Printed Circuit Board) assembly technology, refers to the technology of getting components directly soldered onto the surface of PCB to replace THT (Through-Hole Technology) that has to make use of drilling holes. This article will discuss the essential elements of SMT assembly so that readers are able...

Surface mount technology is a method of assembling electronic components onto a printed circuit board (PCB). Unlike traditional through-hole technology, where the leads of the component are inserted through holes in the PCB, SMT involves mounting the component directly onto the surface of the PCB. SMT offers advantages such as smaller size, higher manufacturing efficiency, and...

Surface Mount Technology (SMT) board assembly is a critical and widely used process in modern PCB manufacturing. This process involves placing and soldering electronic components directly onto the surface of PCB pads. Alongside Plated Through-Hole (PTH) assembly, it is one of the two primary PCB assembly methods. SMT assembly is highly efficient and accurate, making it...

Electronic devices have transformed our lives, from smartphones to electric vehicles, all thanks to continuous innovation and advancements in technology. At the heart of these devices are printed circuit boards (PCBs) that are meticulously manufactured, assembled, and packaged to deliver the final products we rely on. This article explores the PCB Surface Mount Technology (SMT) assembly process,...

Printed circuit boards (PCBs) are at the heart of modern electronic devices, powering everything from smartphones to aerospace systems. The journey of PCB materials has evolved significantly since their inception in the early 20th century. This article explores the composition, types, and advancements of PCB materials, essential for understanding the foundation of today’s electronic innovations. Evolution...

Printed circuit board (PCB) assembly is at the heart of electronic components and gadgets. Designers typically choose between two primary techniques for mounting components on PCBs: SMT (Surface Mount Technology) and PTH (Plated Through Hole). Each method has distinct advantages and disadvantages, making the selection dependent on specific project requirements. What is SMT (Surface Mount Technology)? Surface Mount Technology...

When it comes to assembling Printed Circuit Boards (PCBs), there are two primary technologies: Surface Mount Technology (SMT) assembly and Through-Hole Technology (PTH) assembly. Understanding their differences, advantages, and disadvantages is crucial for selecting the best option for your PCB-based project. This guide by Viasion experts provides a comprehensive comparison to help you make an informed decision. What...