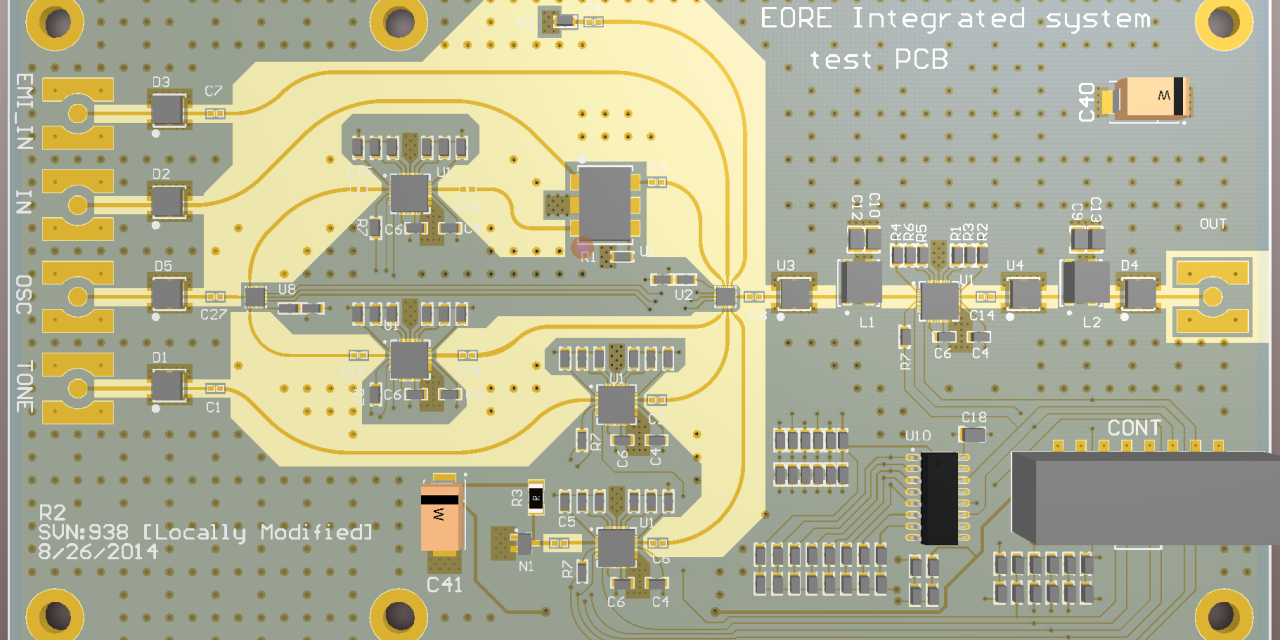

Impedance matching in HDI ( High- Density Interconnect ) boards is intended to prevent transmission errors, especially losses caused by transmission line resistance and the dielectric properties of the printed circuit board. Microvias can be used to create manufacturing-friendly PCB layouts in impedance-matched systems. BGA escape routing and dogbone fanout structures enable impedance matching in HDI PCBs. When do PCB traces...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 3 of 75

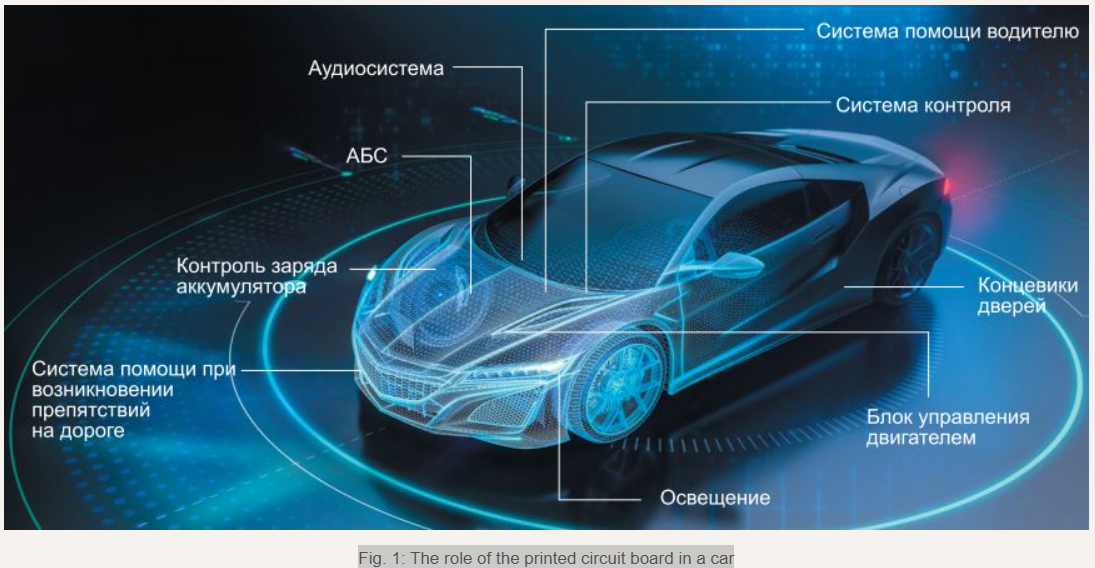

The high level of competition in the modern automotive electronics market encourages manufacturers to constantly introduce new technologies and improve existing features, such as autopilot, automatic parking, emergency braking, keyless start, lane keeping control, and the like. Printed circuit boards (PCBs) are an essential and integral part of any electronic device in a vehicle. Their quality and...

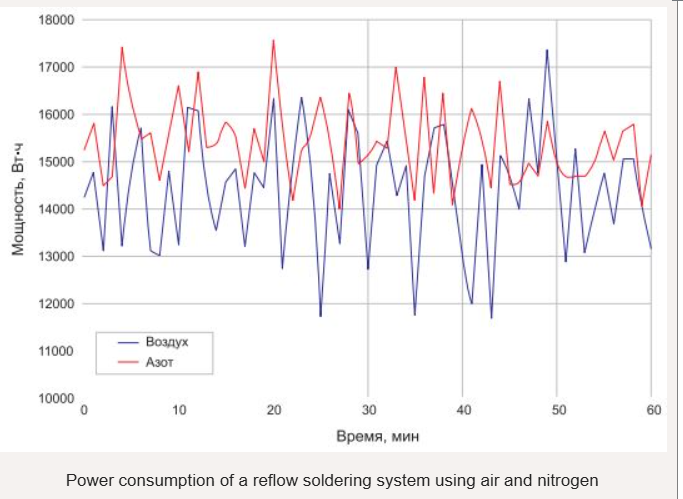

Convection soldering systems remain the primary surface-mount method worldwide, primarily due to their versatility, high efficiency, and excellent heat transfer properties. These properties have become paramount today. The advancement of digitalization, growing production volumes, the diversity of electronic components, and, importantly, the production of printed circuit boards worldwide require efficient and easily configurable production equipment....

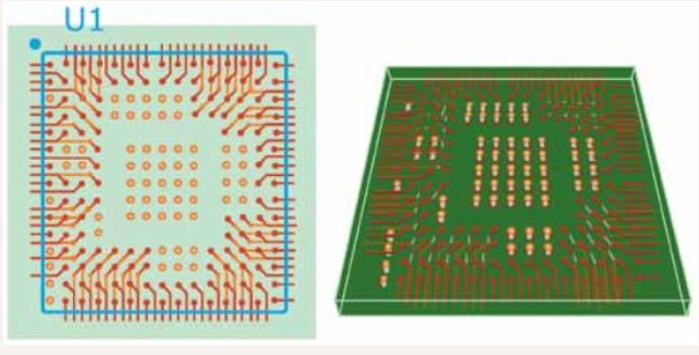

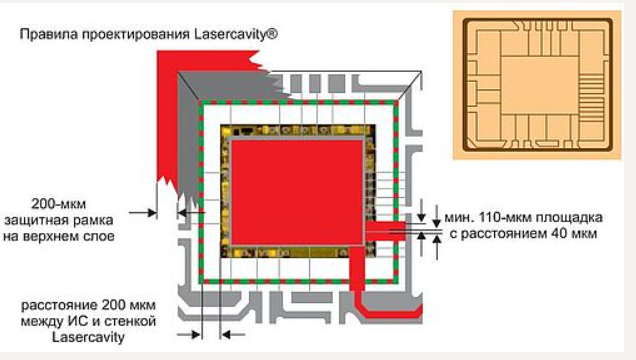

Looking back and examining the evolution of computing technology, we see that many products widely used in everyday life today have changed significantly over time. Looking back at Apollo workstations, the first PCs, and mainframes that could occupy entire floors of buildings, it becomes clear that miniaturization has been the foundation of technological progress. Recent...

Perfect soldering of a printed circuit board is a very simple, yet very rare, phenomenon. How can this contradiction be explained? If perfect soldering is easy, then why so much rework and rework? The answer, of course, is that it is simple, but only if you know how, and also keep in mind that most...

Impedance matching in HDI ( High- Density Interconnect ) boards is intended to prevent transmission errors, especially losses caused by transmission line resistance and the dielectric properties of the printed circuit board. Microvias can be used to create manufacturing-friendly PCB layouts in impedance-matched systems. BGA escape routing and dogbone fanout structures enable impedance matching in HDI PCBs. When do PCB traces...

Flux is the “unsung hero” in the PCBA (Printed Circuit Board Assembly) process, directly affecting solder joint quality, production efficiency, and product reliability. Understanding flux application methods, process characteristics, and key precautions is essential for any electronics manufacturer. This guide explores these aspects to help engineers optimize flux application in PCBA. I. Four Mainstream Flux...

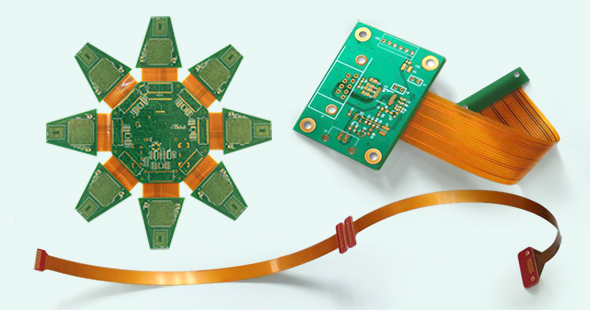

Rigid-flex PCBs combine the flexibility of FPCs with the strength of rigid boards, making them essential in modern electronic devices. Designing high-quality circuits for rigid-flex PCBs requires careful attention to flexible areas, bending zones, and reinforcement materials. This guide explores key challenges and practical solutions for optimal rigid-flex PCB design. 1. Flexible Partition Line Design...

In high-speed and high-frequency electronic applications, RF PCB stack-up design plays a decisive role in ensuring stable performance, minimal signal loss, and electromagnetic compatibility. Proper PCB layer stack-up is not just a structural consideration—it directly determines signal integrity, impedance control, and overall product reliability. This article reveals the core principles of RF PCB stacking, explains...

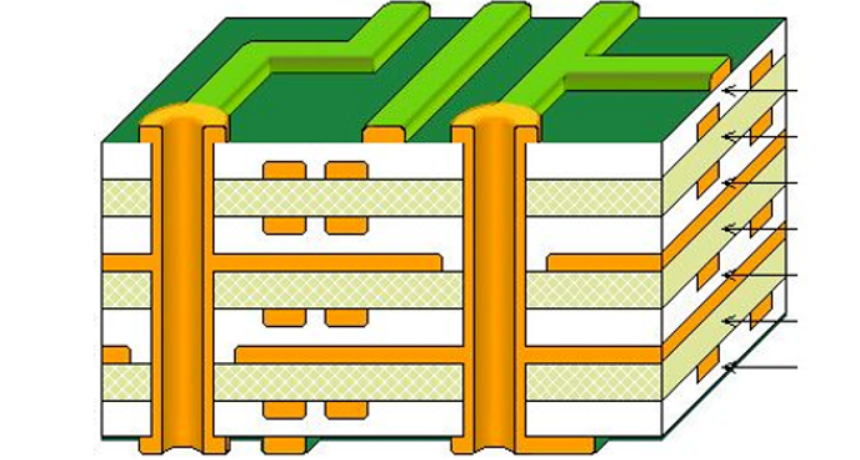

The three main characteristics of Rigid-Flex PCB are Multi-bending, Multi-stackup, and Multi-zone. In the previous article, we discussed multi-bending designs. In this article, we will take a closer look at the multi-layered design of Rigid-Flex. 01、 Multi-Stackup Multi-layer stack Multi-stackup refers to a substrate where the number and thickness of layers differ in different regions, meaning the substrate needs to...