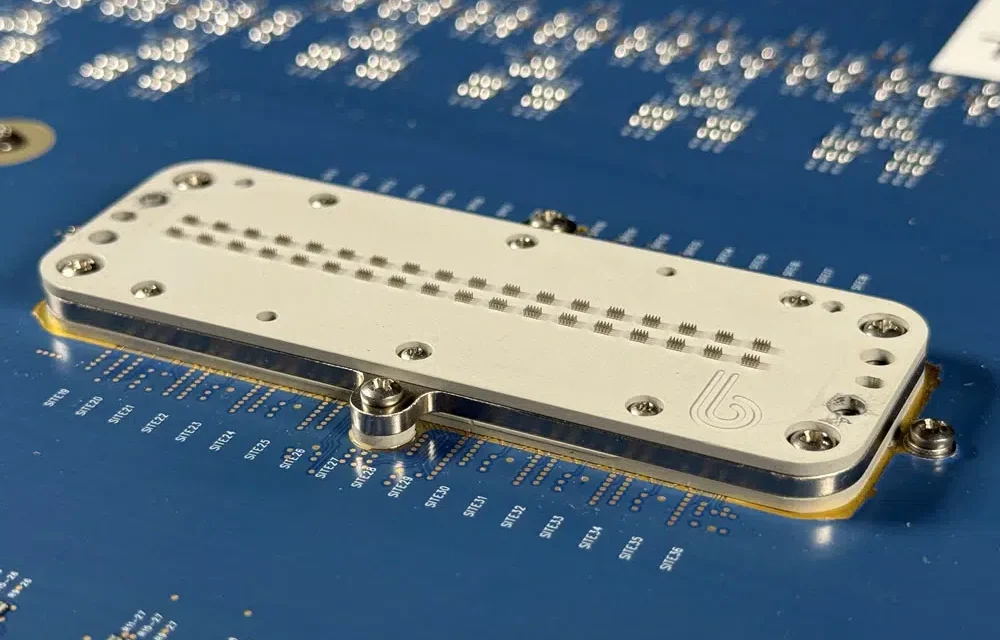

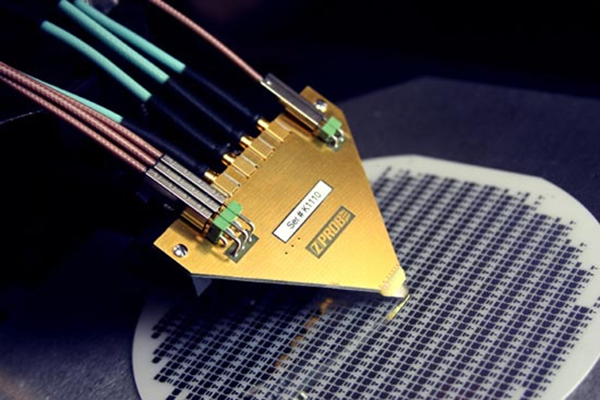

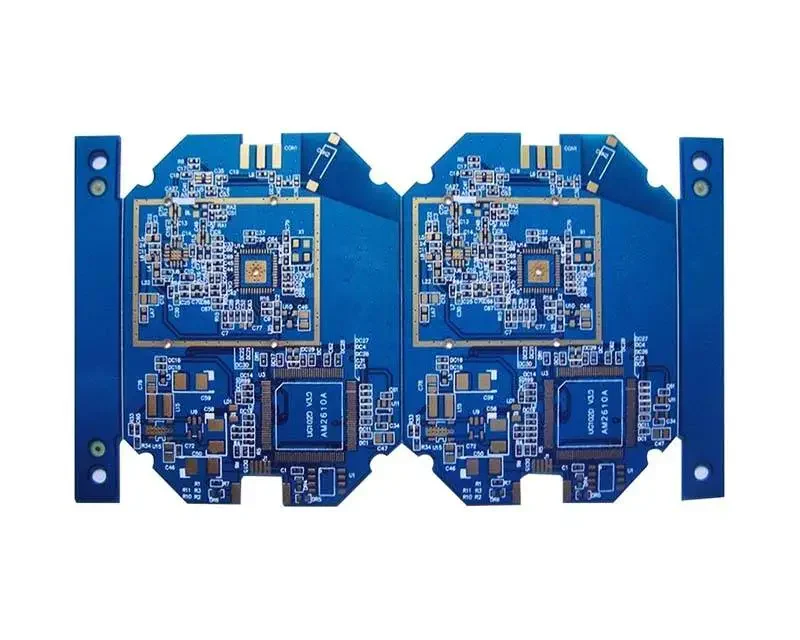

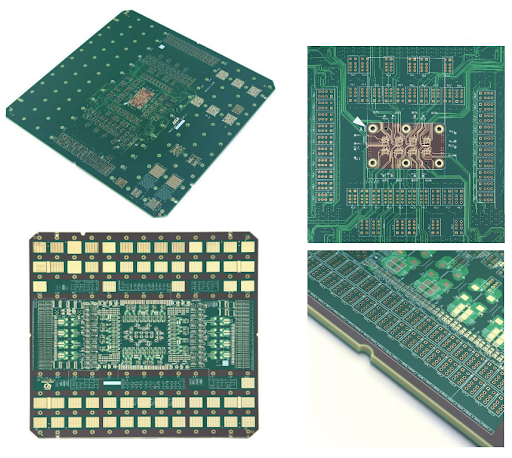

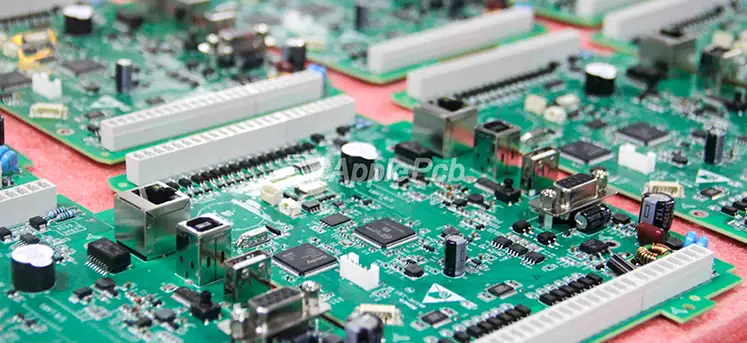

Probe Card PCB Assembly: Precision Assembly Solutions for Wafer-Level Semiconductor Testing

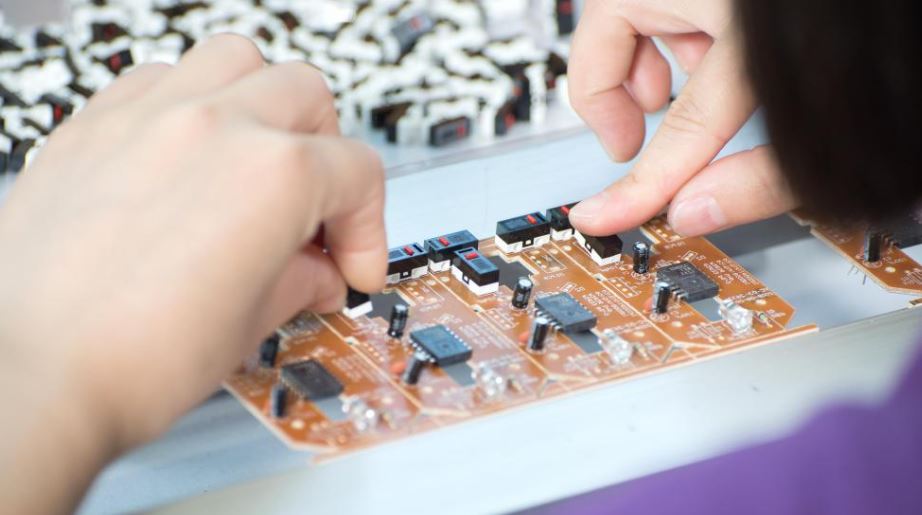

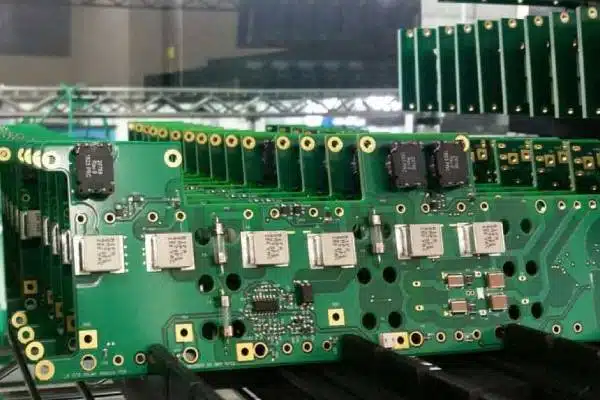

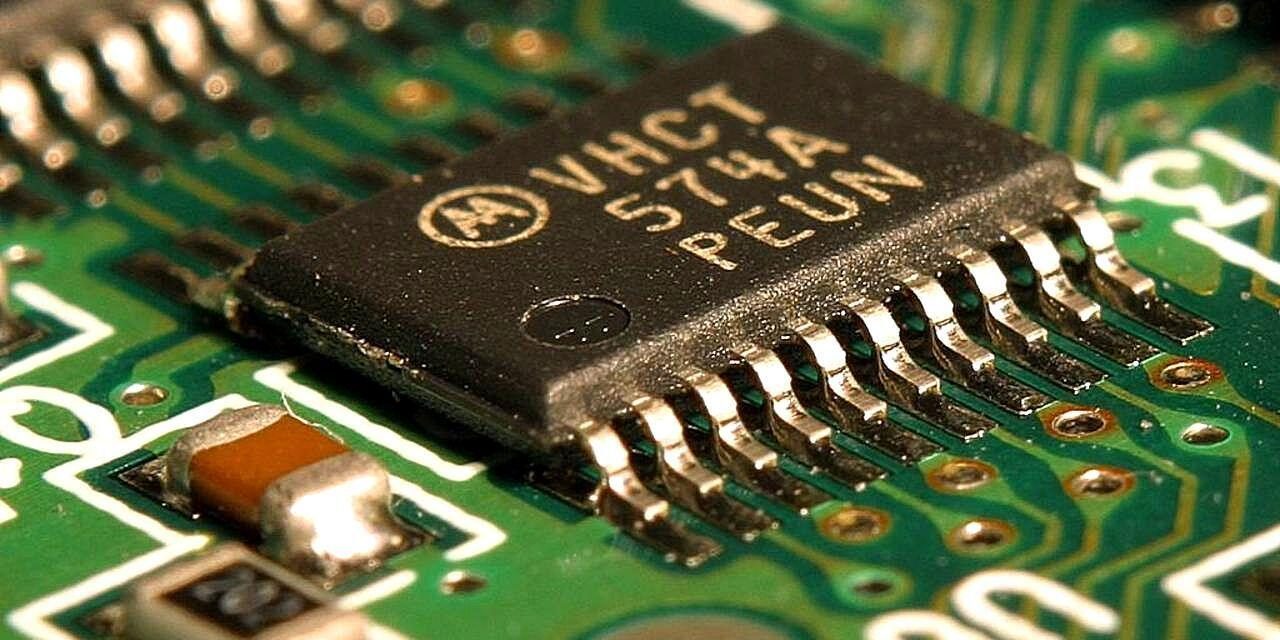

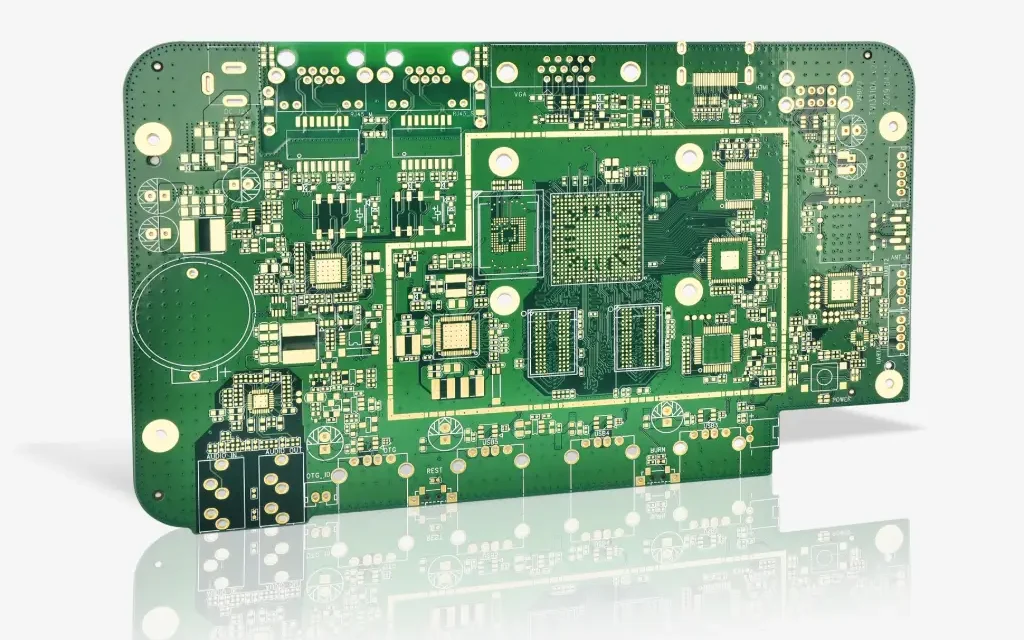

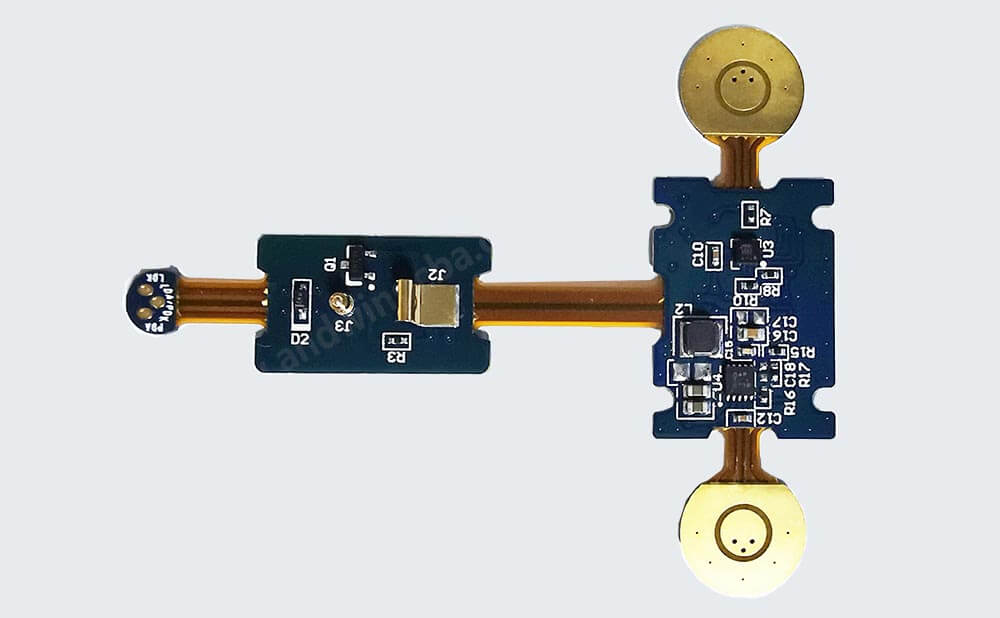

In wafer-level semiconductor testing, accuracy and repeatability are critical. Probe Card PCB Assembly plays a vital role by providing a reliable electrical and mechanical interface between the probe card, the wafer under test, and the automated test equipment (ATE). High-quality probe card PCB assembly ensures stable signal transmission, precise contact alignment, and consistent test performance...