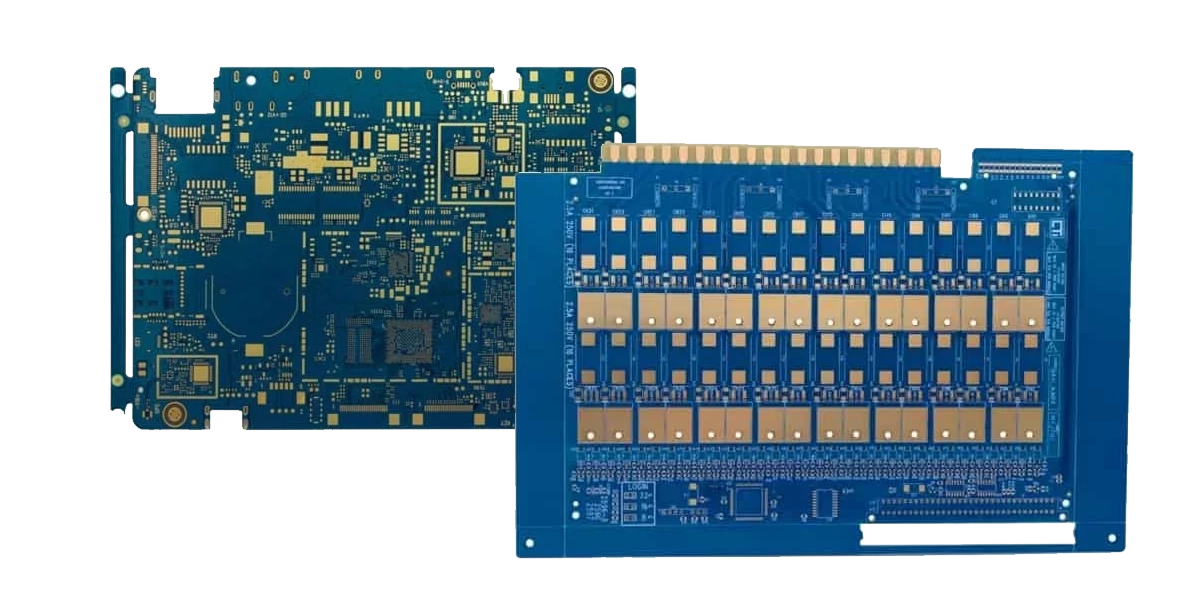

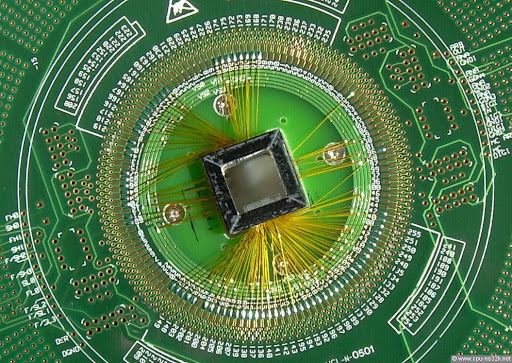

RF IC Test PCB: High-Frequency Testing Solutions for RF and Microwave Chips

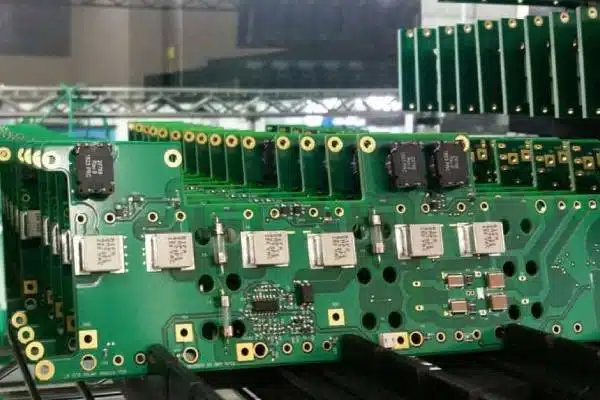

With the rapid growth of 5G, IoT, and wireless communication technologies, RF ICs have become increasingly complex and high-speed. Ensuring the performance and reliability of RF and microwave chips requires specialized IC test PCBs that can handle high-frequency signals while maintaining signal integrity and precise mechanical alignment. RF IC Test PCBs provide the critical interface...