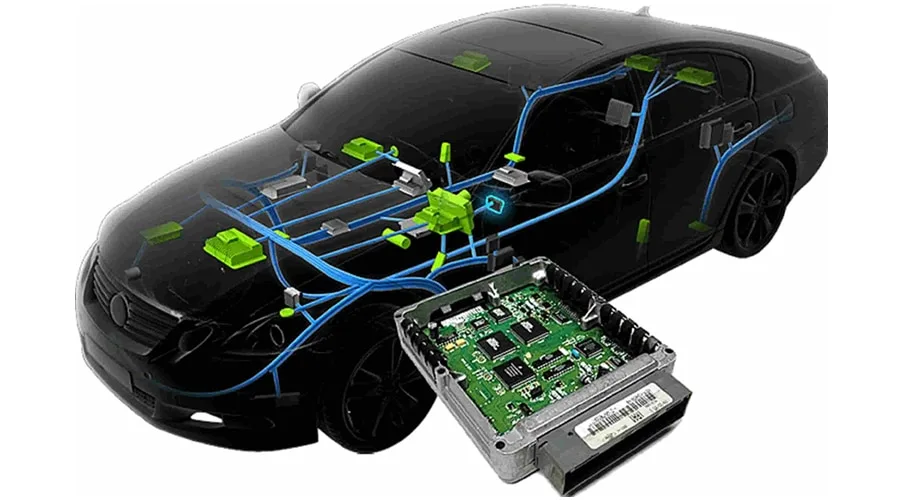

Modern electronics often require boards capable of handling high currents safely and efficiently. High Current PCBs are specially designed to manage large amounts of electrical current while maintaining thermal stability, signal integrity, and mechanical reliability. These PCBs are widely used in power electronics, automotive systems, industrial machinery, and energy storage applications. What is a High...

HomeTag

thermal management - KKPCB

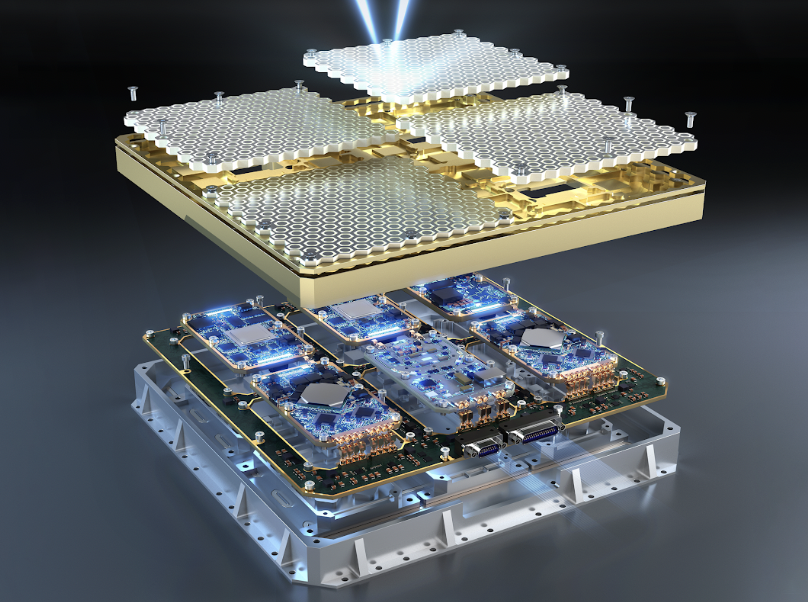

SiC PCB for High-Power Modules and Automotive Powertrain Systems SiC (Silicon Carbide) devices are reshaping high-power electronics. Their wide-bandgap characteristics—high breakdown voltage, fast switching, and elevated junction temperatures—push PCB substrates into thermal, electrical, and mechanical stress profiles that exceed the range of traditional FR-4 and generic high-Tg laminates.A SiC PCB supporting traction inverters, onboard chargers,...

1. Engineering Overview Next-generation 5G base stations require high-density, miniaturized RF front-end modules with low insertion loss, precise impedance, and stable phase performance across mmWave bands (28–39 GHz). PTFE PCB laminates, with Dk = 2.15 ± 0.02 and Df = 0.0009 @10GHz, provide superior dielectric consistency and thermal stability for tightly packed MIMO...

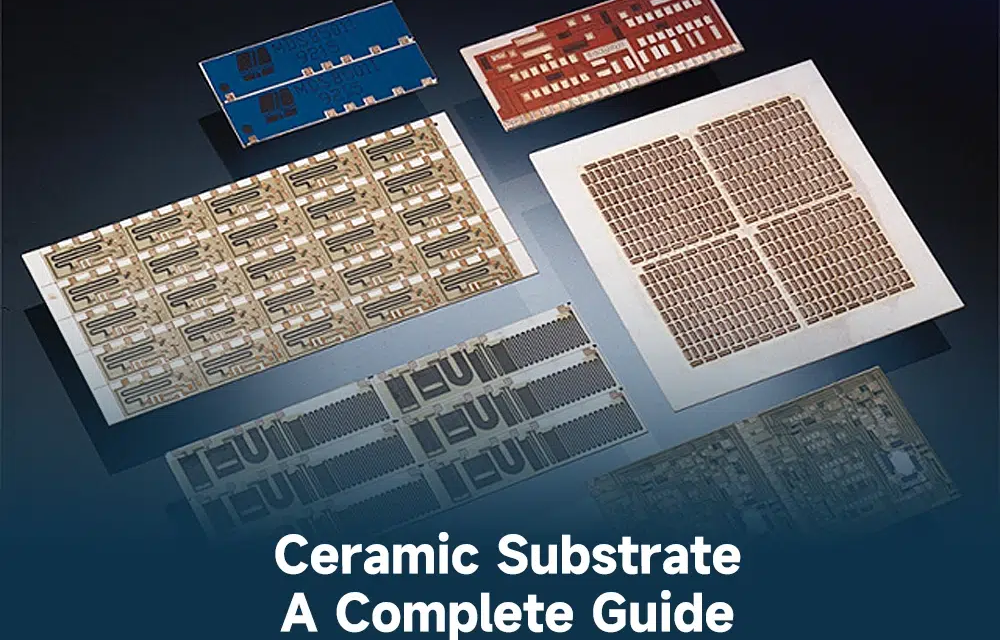

1. Engineering Overview As laptop and server architectures evolve toward higher clock rates and denser power delivery networks, PCB substrates must withstand increasing thermal stress and EMI coupling. Ceramic PCB materials, with their excellent dielectric stability and superior thermal conductivity (>20 W/m·K), provide a robust platform for managing power transients and high-frequency switching noise...

Engineering-Grade Substrate for Miniaturized High-Frequency Circuits As mmWave systems advance toward higher frequencies (30–110 GHz), RF designers face dual challenges: size reduction and signal precision. Compact filters and power amplifiers demand tight impedance control, minimal phase shift, and consistent dielectric behavior even under thermal stress. Rogers Duroid 6010, with a high dielectric constant...

Achieving High-Frequency Reliability and Efficient Heat Dissipation Through KKPCB’s Hybrid Lamination Platform From Material Performance to System-Level Efficiency In industrial mmWave transceiver modules operating from 28 to 81 GHz, engineers face a dual challenge: maintaining signal integrity across multilayer stackups while managing localized power density and heat accumulation.Traditional FR-4 or mid-grade PTFE composites...

Ensuring Low-Loss Transmission and Thermal Reliability Through KKPCB’s Duroid 5880 PCB Engineering 1. Why Duroid 5880 PCB Defines RF Power Amplifier Reliability In modern RF Power Amplifier systems used in defense radar, satellite uplink transmitters, and 5G mmWave base stations,the Duroid 5880 PCB provides exceptional dielectric stability and low-loss performance for power and...

Introduction 5G is not just an upgrade from 4G—it represents a technological leap forward in global connectivity. With ultra-high speed, wide bandwidth, and expanded frequency ranges such as sub-6 GHz and millimeter wave (mmWave), 5G transforms how devices communicate.At the core of this revolution lies one critical component — the Printed Circuit Board (PCB). A...

1. The Growing Thermal Challenge in High-Power RF & mmWave Systems As 5G infrastructure, satellite communication, and automotive radar systems push beyond 24–81 GHz, PCB substrates face new levels of thermal density and mechanical stress. In these high-frequency environments, heat is not just a byproduct — it’s a design-defining variable that directly influences signal...

Heat Dissipation Challenges in High-Power RF Circuits As RF and mmWave systems scale beyond 24 GHz, power density and thermal stress become critical limiting factors for system reliability. Engineers designing automotive radar front-ends, 5G transceivers, and satellite payloads must manage high localized temperatures within densely packed multilayer PCBs. While traditional FR-4 substrates often...