Between prototype validation and mass production, test engineers require repeatable manufacturing that reflects real production conditions. Small Batch ATE PCB manufacturing delivers controlled, low-volume builds that ensure electrical consistency, mechanical reliability, and scalable processes for automated test equipment. Small batch ATE PCBs are essential for system qualification and risk reduction. What Defines a Small Batch...

HomeTag

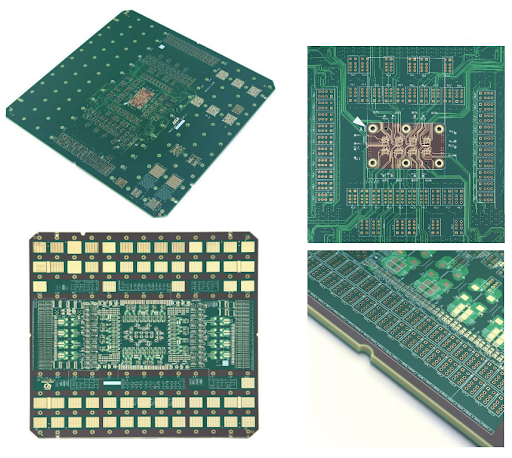

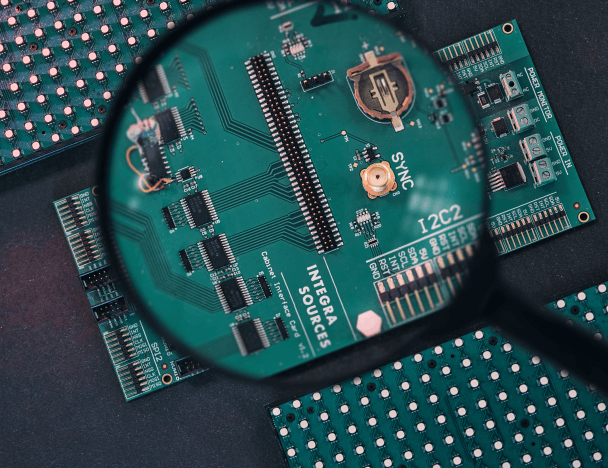

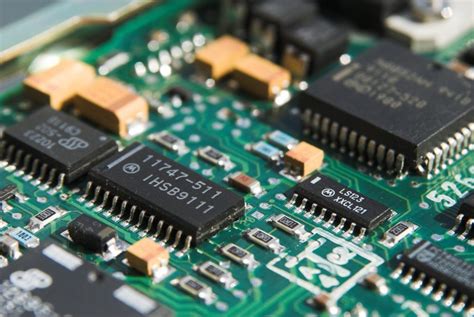

semiconductor test PCB - KKPCB

In automated test equipment development, early-stage validation determines long-term system reliability. The ATE PCB Prototype provides a controlled platform for verifying electrical performance, mechanical interfaces, and test repeatability before production deployment. A well-designed ATE PCB prototype reduces risk and accelerates development cycles. Role of ATE PCB Prototypes in Test Engineering An ATE PCB Prototype bridges...

As data rates continue to increase across modern electronics, validating high-speed signals becomes more challenging. The High Speed Test PCB provides a stable and repeatable platform for evaluating signal integrity, timing, and performance in high-speed digital and mixed-signal systems. High speed test PCBs are essential for accurate measurement and debugging. What Is a High Speed...

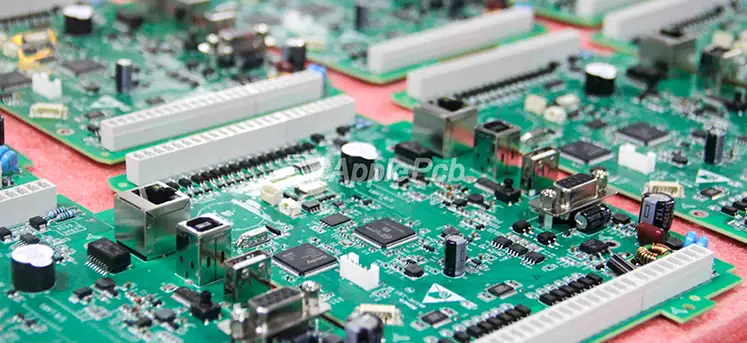

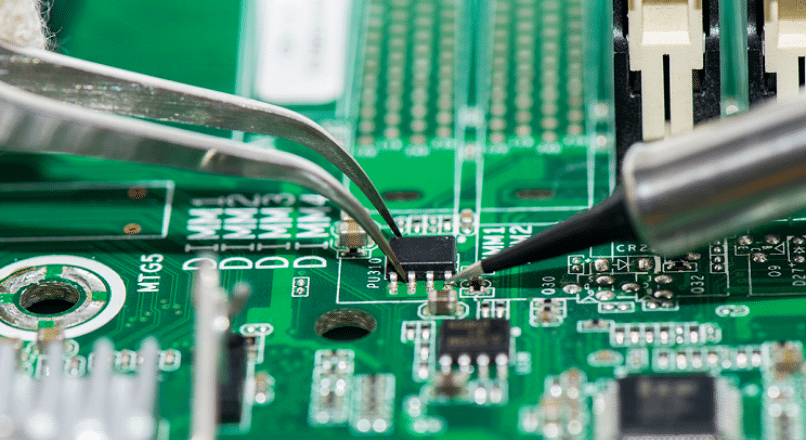

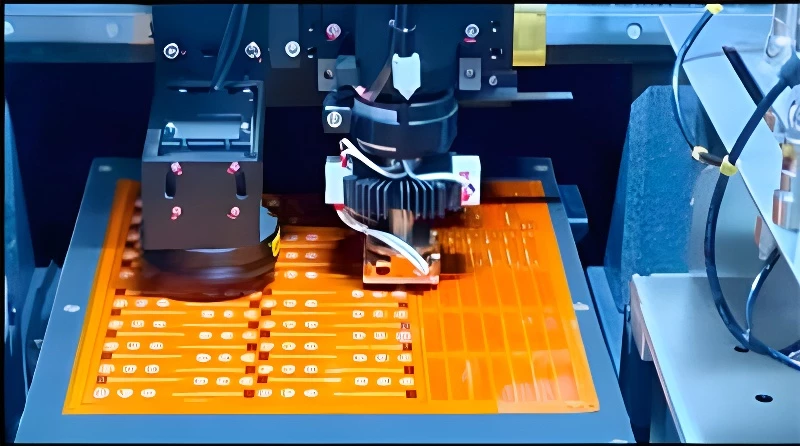

Automated test equipment relies not only on PCB design and fabrication, but also on precise and repeatable assembly. ATE PCB Assembly plays a critical role in ensuring signal integrity, power stability, and mechanical reliability throughout semiconductor testing operations. High-quality assembly directly impacts test accuracy and system uptime. What Is ATE PCB Assembly? ATE PCB Assembly...

As automated test equipment evolves to support faster data rates and higher pin counts, PCB complexity increases significantly. The High Layer Count ATE PCB provides the routing density, power integrity, and signal control required for modern semiconductor testing. High layer count designs are essential for advanced ATE performance and scalability. What Is a High Layer...

As test systems become more compact and complex, traditional rigid PCBs often struggle to meet mechanical and routing constraints. The Rigid-Flex Test PCB combines rigid board stability with flexible interconnections, enabling reliable testing in space-limited and mechanically dynamic environments. Rigid-flex technology is increasingly essential for modern test and validation platforms. What Is a Rigid-Flex Test...

Between initial prototyping and full-scale production, test engineers often require a controlled, repeatable manufacturing stage. Small batch ATE PCB production fills this gap by providing consistent quality, stable electrical performance, and scalable processes for automated test equipment (ATE) development. Small batch manufacturing enables engineering teams to validate real production conditions without the risks of mass...

Before an automated test system enters production, its electrical and mechanical behavior must be thoroughly validated. The ATE PCB Prototype serves as the critical platform for early-stage verification, allowing engineers to evaluate signal integrity, power delivery, and interface compatibility under real test conditions. A well-executed ATE PCB prototype reduces development risk and accelerates time to...

As data rates continue to increase, validating high-speed digital interfaces requires test platforms that introduce minimal distortion. The High Speed Test PCB is engineered to act as a transparent signal medium, enabling accurate characterization of high-speed devices and systems. A well-designed high speed test PCB ensures that test results reflect real device performance rather than...

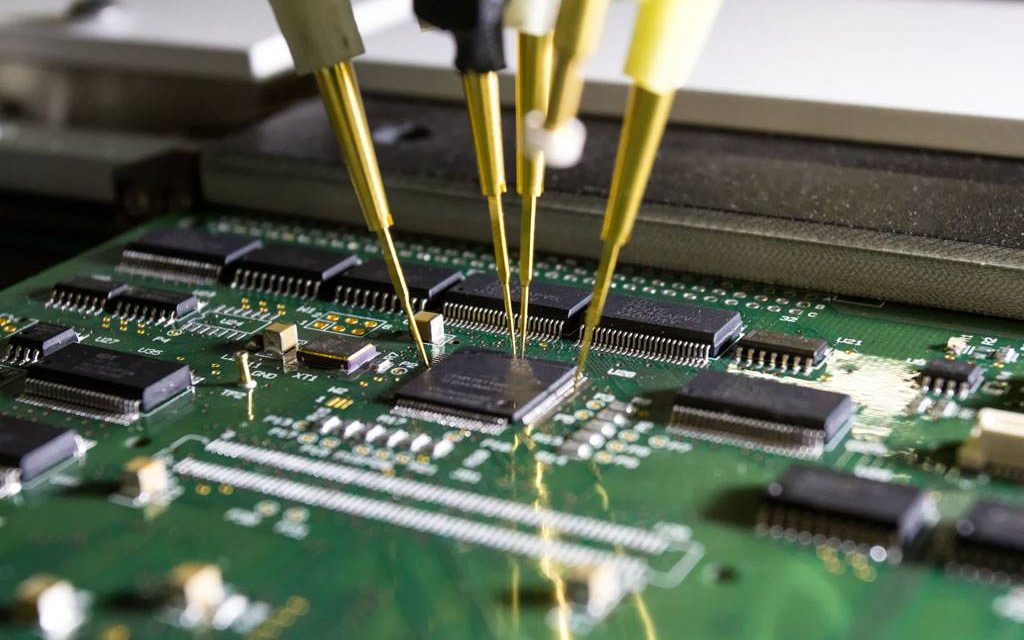

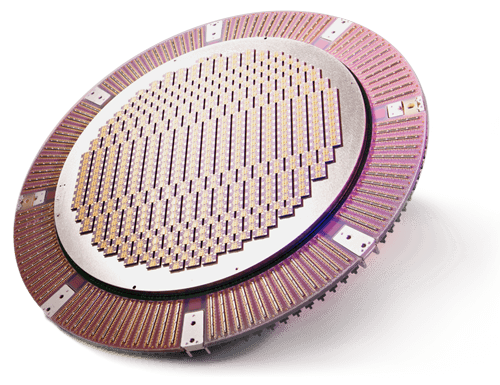

In wafer-level semiconductor testing, even microscopic assembly deviations can lead to unstable probe contact and inconsistent measurements. Probe Card PCB Assembly is a highly specialized process that integrates probe structures, connectors, and high-density routing into a mechanically and electrically stable test platform. A professionally executed probe card PCB assembly directly determines test accuracy, probe lifetime,...