5G router PCB platforms operate under multi-band RF loads, high-density routing, and continuous thermal cycling in compact CPE enclosures. Achieving stable RF efficiency requires a stackup engineered around low-loss materials, controlled dielectric stability, and carefully optimized thermal paths. This article analyzes how engineered 5G router PCB stackups improve RF efficiency, insertion-loss performance, and long-term thermal...

HomeTag

mmWave PCB - KKPCB

What Is a Low Loss PCB? Premium Materials, Performance Advantages & Applications In high-frequency electronics, signal integrity is everything. As data rates climb and RF systems move into the mmWave range, traditional FR-4 PCBs quickly become inadequate due to excessive dielectric loss, copper loss and thermal instability. At KKPCB, we engineer Low Loss PCBs specifically...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB Assembly (PCBA)PCB DesignPCB Materials

RF PCB Design for 5G Devices: Antenna Integration, Impedance Control & High-Frequency Layout Guide

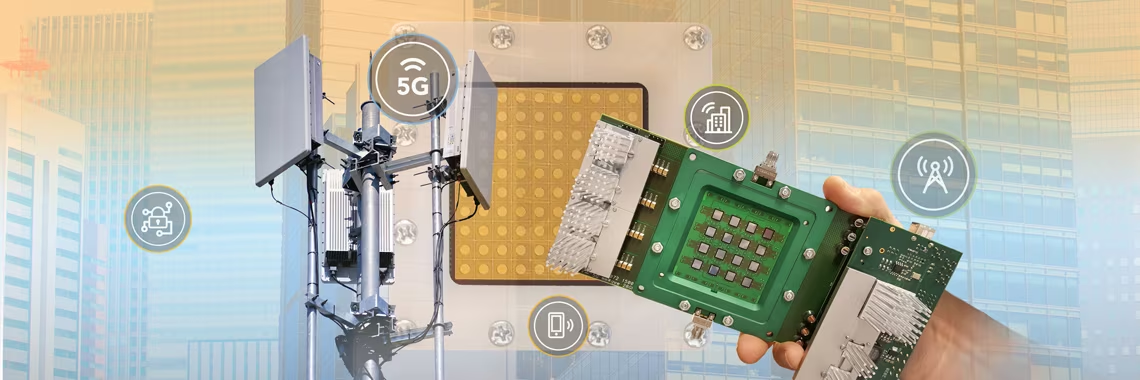

RF PCB Design for 5G Devices: High-Frequency Architecture, Antenna Integration & Engineering Best Practices Designing RF PCBs for 5G hardware is far more than simple high-speed layout—it requires a deep command of electromagnetic behavior, antenna engineering, high-frequency signal routing, impedance control, and noise isolation.In next-generation wireless systems, the antenna is no longer a passive component—it...

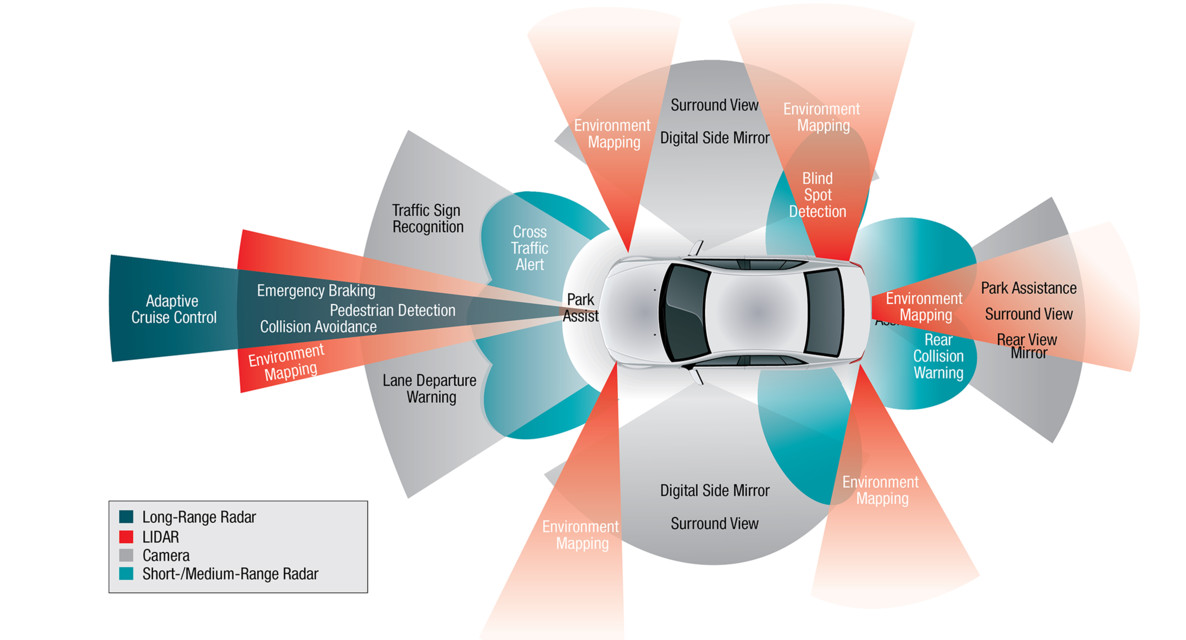

Microwave Module PCB: Precision Engineering for High-Frequency Excellence at KKPCB As wireless systems enter the microwave and millimeter-wave domain—from 2 GHz radar to 30 GHz satellite links and even 77 GHz ADAS—the role of the Microwave Module PCB becomes mission-critical. These PCBs are no longer just interconnect structures; they function as precision RF substrates, thermal...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

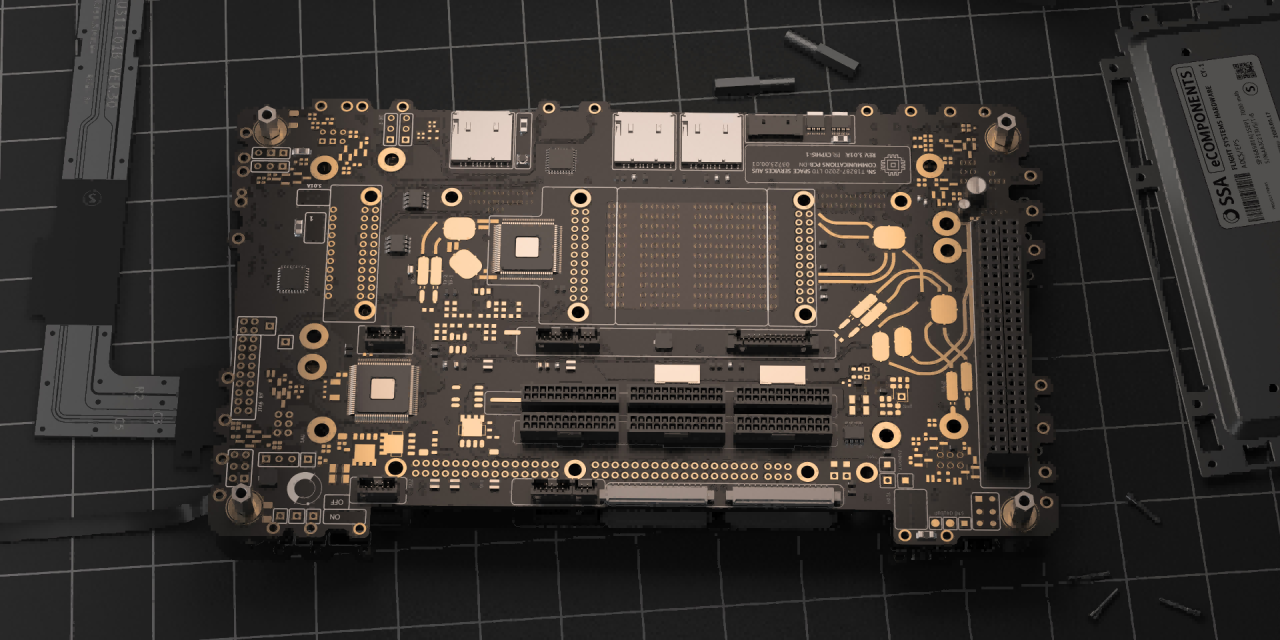

5G Module PCB Solutions: Empowering Next-Generation Connectivity

Introduction In the era of hyper-connectivity, the evolution of 5G technology has brought about an unprecedented leap in wireless communication. From smartphones and IoT devices to autonomous vehicles and industrial automation, 5G enables ultra-fast data transfer, ultra-low latency, and seamless device interconnection. At the heart of this revolution lies the 5G Module PCB — the...

1. Engineering Overview / Abstract Automotive radar technology operating in the 76–81 GHz band demands printed circuit boards with extremely low dielectric loss, phase stability, and high thermal endurance. Taconic TLY-5 PCB laminates—featuring a Dk of 2.20 ± 0.02 and Df of 0.0009 @ 10 GHz—offer a robust foundation for mmWave antenna arrays, signal...

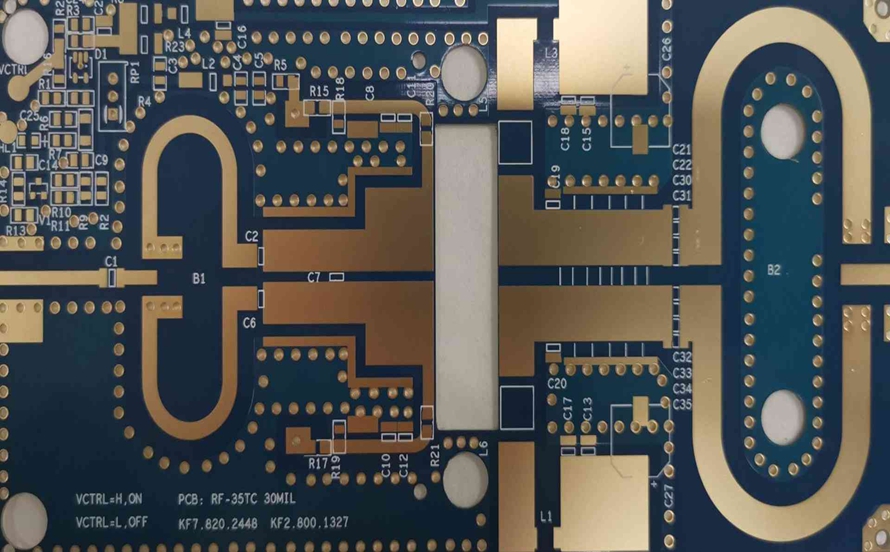

1. Introduction In advanced RF and microwave test systems, where signal accuracy defines measurement integrity, the substrate material directly determines consistency. The RF-35 PCB—a low-loss laminate with optimized dielectric uniformity—has become a preferred platform for network analyzers, calibration modules, and power sensors operating between 20 GHz to 50 GHz. KKPCB’s engineering framework addresses key...

1. The Growing Thermal Challenge in High-Power RF & mmWave Systems As 5G infrastructure, satellite communication, and automotive radar systems push beyond 24–81 GHz, PCB substrates face new levels of thermal density and mechanical stress. In these high-frequency environments, heat is not just a byproduct — it’s a design-defining variable that directly influences signal...

Building the Backbone of 5G Antenna Performance with RO4350B PCB As 5G networks evolve toward higher frequencies (sub-6 GHz → mmWave) and denser integration, PCB performance has become a decisive factor in antenna module design.Engineers must now balance low insertion loss, thermal stability, and mass-production manufacturability—a challenge only a few materials can meet. That’s why...

1. Executive summary RO3003 (Rogers RO3000 series) is a PTFE-based, ceramic-filled laminate widely adopted where low dielectric loss, stable Dk, and excellent dimensional stability are required. This article explains why RO3003 is often the substrate of choice for automotive radar (e.g., 24 GHz, 77 GHz) and 5G mmWave antenna systems (e.g., 24–40 GHz), then walks...