1. Engineering Overview / Abstract Modern medical imaging systems — including MRI coils, ultrasound transceivers, and RF diagnostic sensors — rely on tight impedance control and ultra-low signal drift to ensure accurate imaging and patient diagnostics. The Taconic TLY-5 PCB platform, with its Dk of 2.20 ± 0.02 and Df of 0.0009 @10GHz, provides...

HomeTag

low-loss PCB - KKPCB

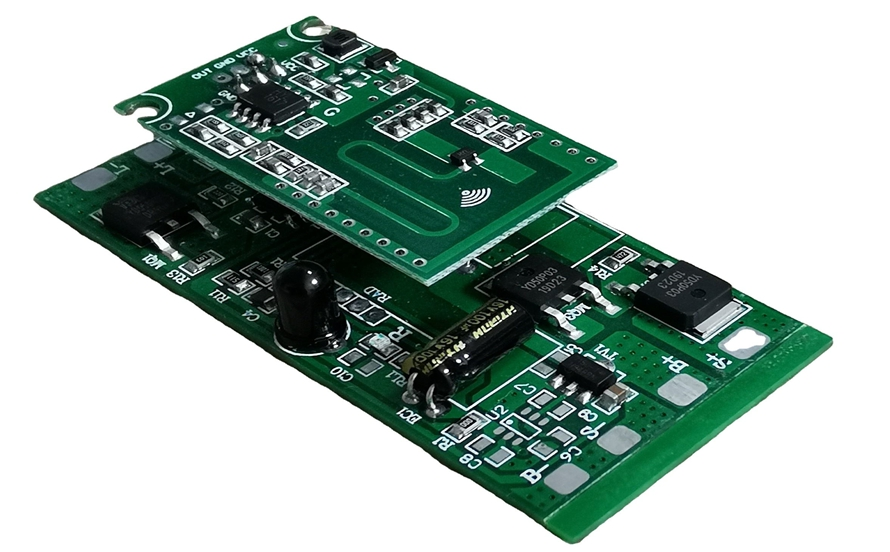

1. Engineering Overview / Abstract As industrial wireless sensor networks (IWSNs) expand into high-density, real-time monitoring environments, the printed circuit substrates must provide low dielectric variation, minimal insertion loss, and superior RF efficiency. Taconic TLY-5 PCB laminates, with a Dk of 2.20 ± 0.02 and Df of 0.0009 @10GHz, deliver exceptional signal integrity and...

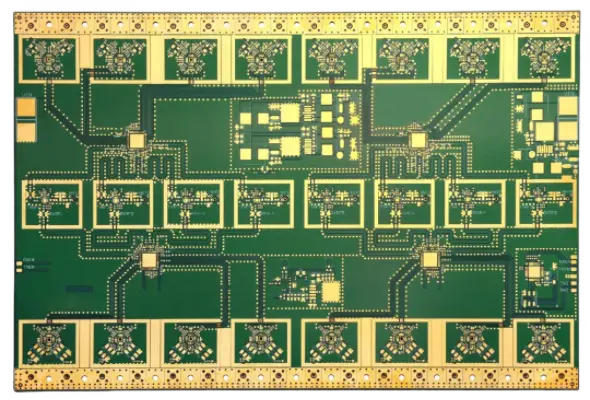

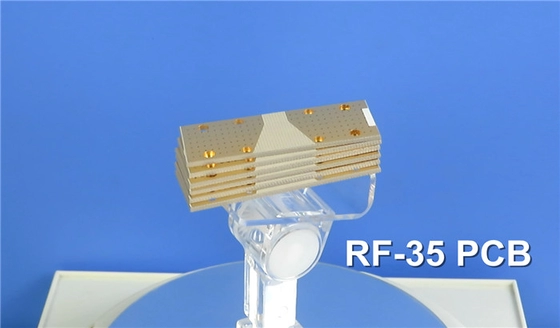

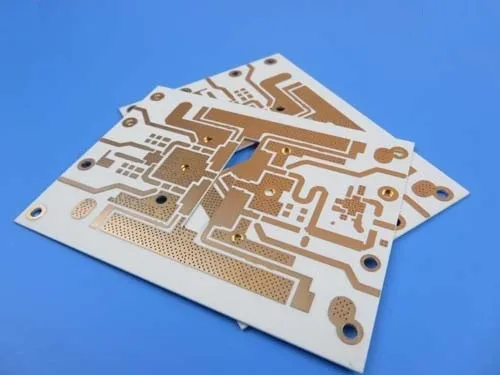

1. Engineering Overview / Abstract As precision RF test and measurement systems extend into the 40 – 110 GHz range, achieving sub-degree phase accuracy and minimal insertion-loss drift becomes a primary design requirement. Taconic RF-35 PCBs—engineered with a glass-reinforced PTFE composite (Dk = 3.50 ± 0.05, Df = 0.0018 @ 10 GHz)—enable calibration-grade impedance...

1. Engineering Overview — PCB Reliability in Industrial Wireless Sensor Networks As industrial IoT systems expand to high-density wireless sensor networks (WSNs), the RF front-end and communication nodes must sustain stable dielectric properties and low signal loss across wide temperature and humidity ranges. Factories often feature high EMI levels, long sensor link distances,...

1. Engineering Overview — PCB Demands in Automotive mmWave Radar and ADAS As vehicles move toward Level 3–5 autonomous driving, radar and vision-based sensing systems rely on 77–81 GHz mmWave modules and ultra-low-loss PCB interconnects. These radar PCBs must maintain electrical precision while enduring extreme temperature cycling, vibration, and humidity. KKPCB integrates TLY-5...

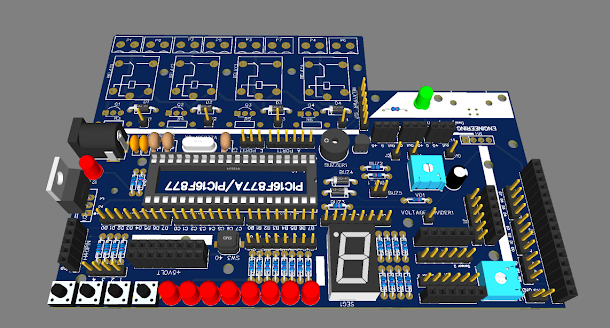

1. Engineering Overview — Power and EMI Challenges in High-Speed Computing Boards As laptops and enterprise servers transition to PCIe 5.0/6.0 and DDR5 architectures, maintaining power integrity (PI) and electromagnetic interference (EMI) control becomes a core constraint in multilayer PCB design. The TLY-5 PCB, with its ultra-low Dk (2.20 ± 0.02) and low Df...

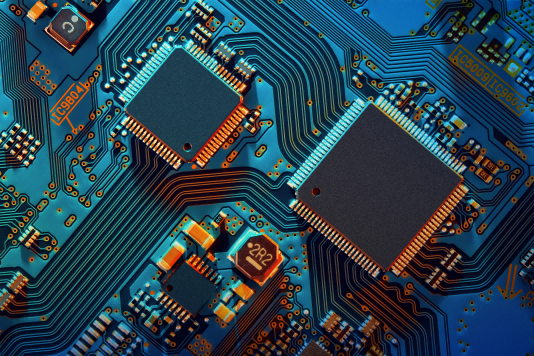

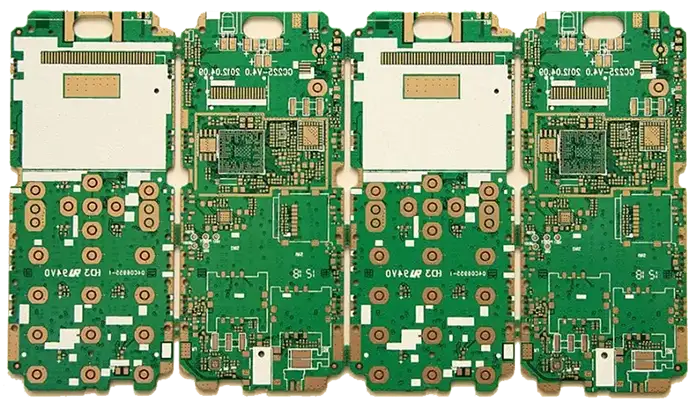

1. Engineering Overview — Material-Driven Signal Reliability for 5G Smartphones As 5G smartphones evolve toward multi-antenna, wide-band, and ultra-compact RF front-end architectures, PCB materials play a decisive role in ensuring signal alignment and thermal stability. The TLY-5 PCB, a PTFE-glass composite laminate from Taconic, provides excellent dielectric uniformity (Dk = 2.2 ± 0.02, Df...

Introduction As electronic systems continue to evolve toward higher frequencies and faster data rates, the need for advanced laminate materials becomes increasingly critical. Among the top performers in RF and microwave PCB substrates, Taconic RF-35 has gained industry-wide recognition for its outstanding signal integrity, thermal stability, and material uniformity.With a dielectric constant (Dk) of 3.5,...

Ensuring Phase-Consistent Measurement Accuracy Through KKPCB’s Ultra-Low-Loss RF Manufacturing Platform As mmWave calibration and test systems advance into the 40–110 GHz domain, every transmission line, connector, and RO5880 PCB trace within the measurement chain directly influences phase linearity and amplitude accuracy.Even a minor 0.1 dB loss variation or 1° phase shift can distort calibration...

Signal Integrity — The Invisible Backbone of mmWave Performance As 5G networks and radar systems transition into 24–77 GHz mmWave frequencies, signal integrity (SI) has become one of the most critical yet challenging aspects of RF PCB engineering. At these frequencies, every micron of copper geometry, dielectric uniformity, and via structure directly influences...