RF subsystems operating from 10 to 67 GHz—spanning 5G mmWave, satellite links, and aerospace communication modules—demand ultra-stable dielectric properties and minimal signal loss. Any Dk/Df variation or thermal-induced impedance drift directly degrades signal integrity, phase coherence, and overall RF system efficiency. Duroid 5880 PCB laminates (Dk = 2.2 ± 0.02, Df = 0.0009 @10 GHz)...

HomeTag

impedance control - KKPCB

5G mmWave hardware doesn’t leave much room for layout mistakes. When operating above 24 GHz, a few microns of misalignment, a poorly shaped via stub, or an uncontrolled dielectric transition can collapse RF integrity. That is why advanced blind via PCB layouts have become a core enabling technology for minimizing crosstalk, stabilizing impedance, and preserving...

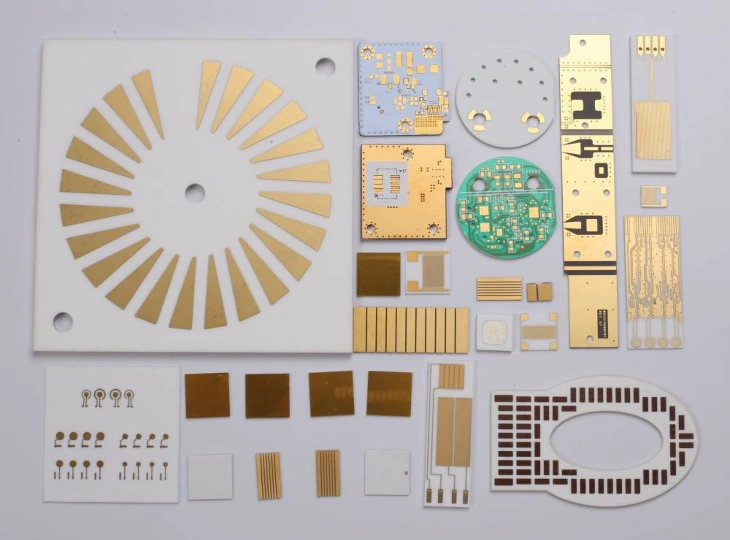

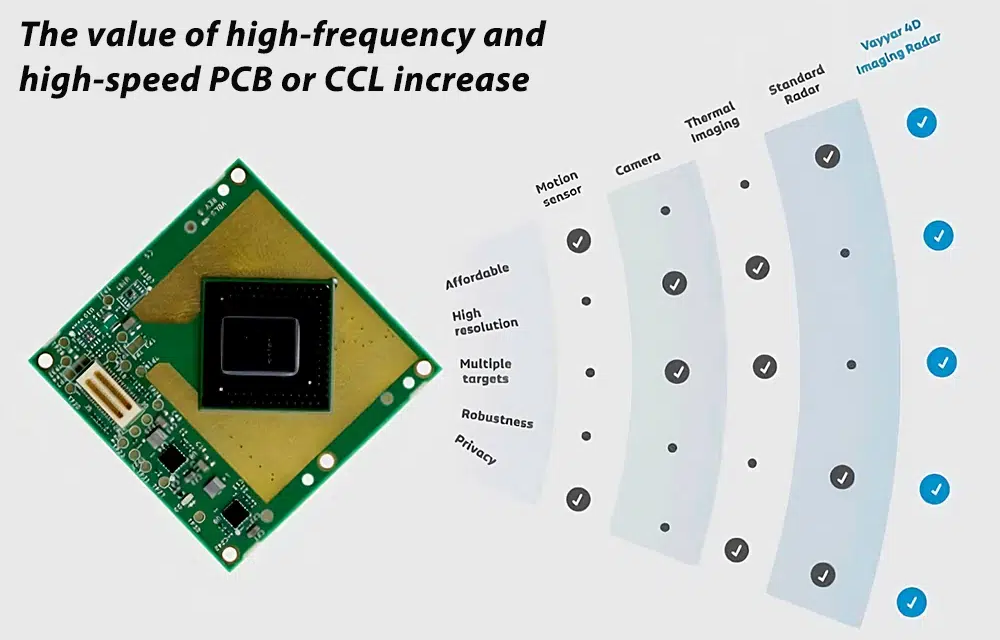

Radar PCB: Design Principles, Materials, Manufacturing Challenges & Key Applications High-speed PCBs stand at the top of modern circuit-board technology, spanning digital high-speed, mixed-signal, and RF/microwave categories. Among these, RF and microwave PCBs operate at the highest frequencies, making them essential for advanced applications—especially RADAR (Radio Detection and Ranging). Because Radar PCBs frequently host a...

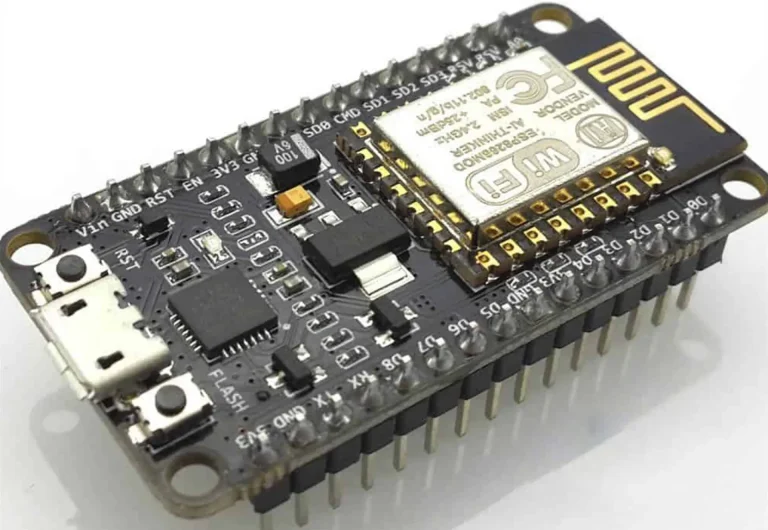

WiFi PCB Design Guide for High-Speed Connectivity Introduction WiFi connectivity is everywhere—from mobile devices to smart home systems and industrial machinery. At the heart of all these wireless systems lies the WiFi PCB, a specialized circuit board engineered to process, transmit, and receive high-frequency wireless signals. This guide explores the structure, design principles, materials, RF...

1. Engineering Overview Next-generation 5G base stations require high-density, miniaturized RF front-end modules with low insertion loss, precise impedance, and stable phase performance across mmWave bands (28–39 GHz). PTFE PCB laminates, with Dk = 2.15 ± 0.02 and Df = 0.0009 @10GHz, provide superior dielectric consistency and thermal stability for tightly packed MIMO...

Dielectric Uniformity and Manufacturing Precision of PTFE PCBs for Aerospace Communication Equipment

1. Engineering Overview Modern aerospace RF communication equipment, including satellite transceivers and spaceborne antenna modules, demands ultra-low-loss PTFE PCBs with tight dielectric uniformity and precise manufacturing tolerances. Small variations in Dk or CTE can lead to phase drift, impedance mismatch, and degraded link margin in Ku/Ka-band RF payloads. PTFE PCB laminates, with Dk...

1.Engineering Overview / Abstract Modern satellite communication payloads operating in Ka- and Ku-band frequencies require PCB substrates with ultra-low loss, precise impedance control, and stable phase performance. PTFE PCB laminates provide an ideal platform for high-frequency RF interconnects due to their low dielectric constant (Dk = 2.10 ± 0.03) and minimal loss tangent (Df...

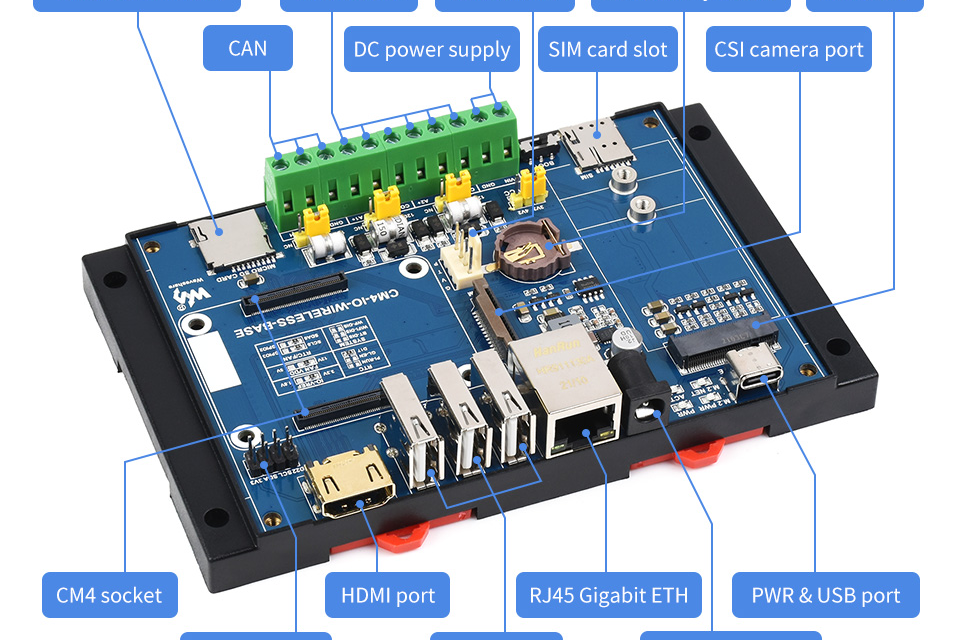

1. Engineering Overview / Abstract As Industrial IoT communication modules become more compact and operate at higher frequencies, maintaining precise impedance control and RF efficiency is critical for reliable data transmission. Traditional polymer-based PCBs often suffer from dielectric drift, thermal warpage, and EMI coupling, which degrade signal integrity in dense wireless sensor networks. Ceramic...

1. Engineering Overview Automotive mmWave radar modules for advanced driver-assistance systems (ADAS) require precise RF signal propagation with minimal loss and stable impedance across multilayer PCBs. Trace density and high-frequency operation introduce challenges in maintaining signal integrity and crosstalk suppression. Megtron 7 PCBs, with Dk = 3.40 ±0.02 and Df = 0.0018 @ 10...

1. Engineering Overview / Abstract Modern medical imaging systems — including MRI coils, ultrasound transceivers, and RF diagnostic sensors — rely on tight impedance control and ultra-low signal drift to ensure accurate imaging and patient diagnostics. The Taconic TLY-5 PCB platform, with its Dk of 2.20 ± 0.02 and Df of 0.0009 @10GHz, provides...