Why PCB Turnkey Matters in Modern Electronics Manufacturing As electronic systems become more complex, managing separate suppliers for PCB fabrication, component sourcing, assembly, and testing introduces cost risk, schedule delays, and quality uncertainty. This is especially true for products involving high-speed digital signals, RF circuits, power electronics, or mixed-technology assemblies. PCB turnkey solutions address this...

HomeCategory

Advanced Engineering Technologies for PCB & PCBA Solutions - KKPCB

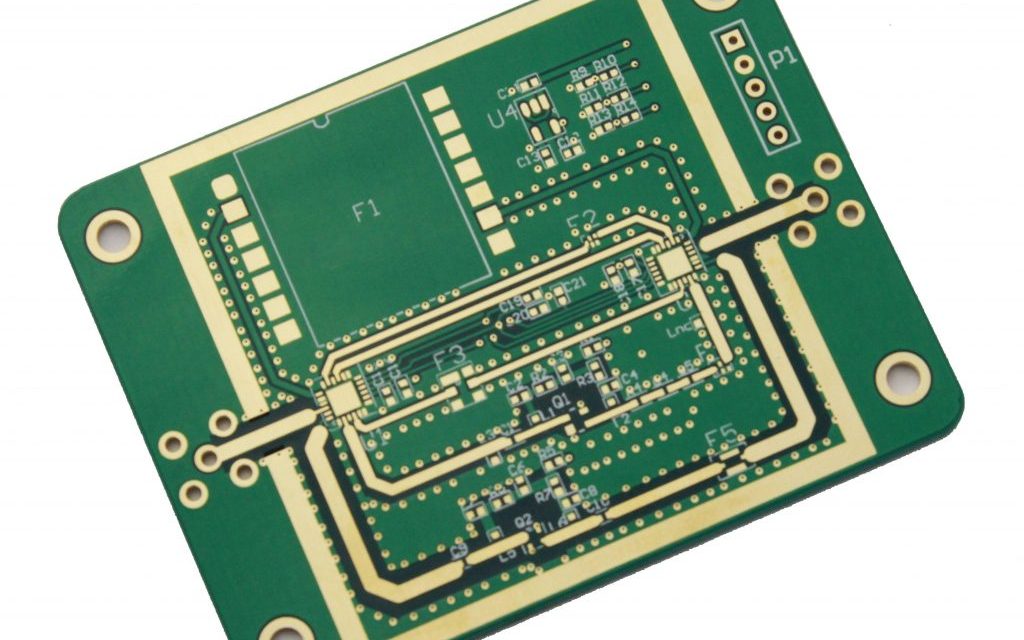

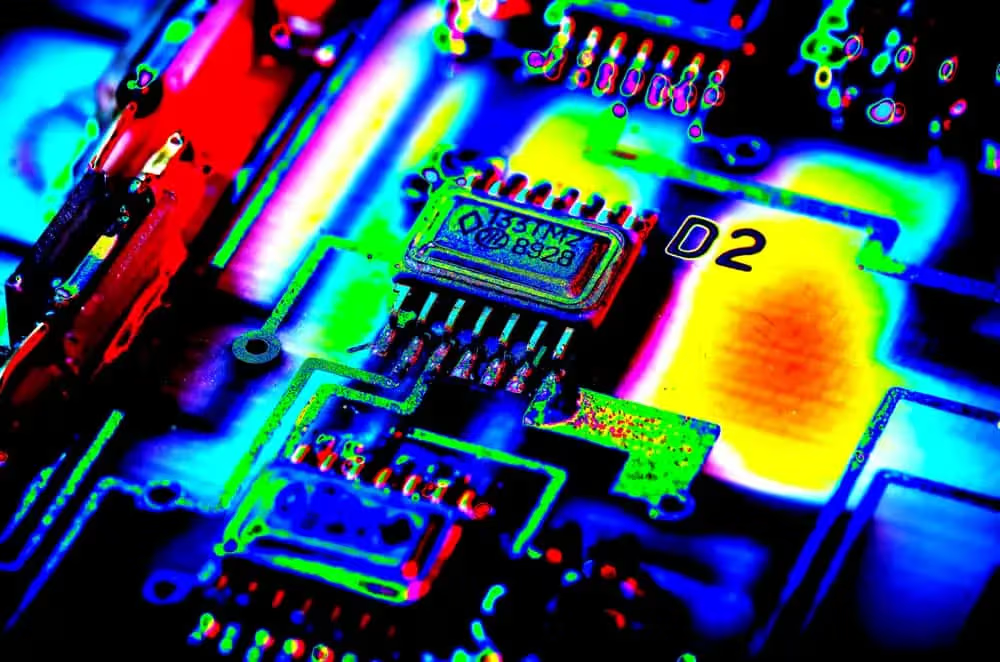

Introduction: Why Controlled Impedance Defines High-Speed Reliability As high-speed electronics push into multi-gigabit data rates and high-frequency RF domains, signal behavior is no longer dominated by logic thresholds—it is governed by transmission line physics. In these systems, every PCB trace behaves as a controlled impedance structure, and any deviation can introduce reflections, timing skew, and...

With the rapid development of high-frequency and high-reliability electronic products, the limitations of traditional ENIG (Electroless Nickel Immersion Gold) surface finishes have become increasingly evident. EPIG (Electroless Palladium Immersion Gold) has emerged as an advanced alternative, especially for RF, microwave, and fine-pitch PCB applications. This article, optimized and technically interpreted by KKPCB, presents a comparative...

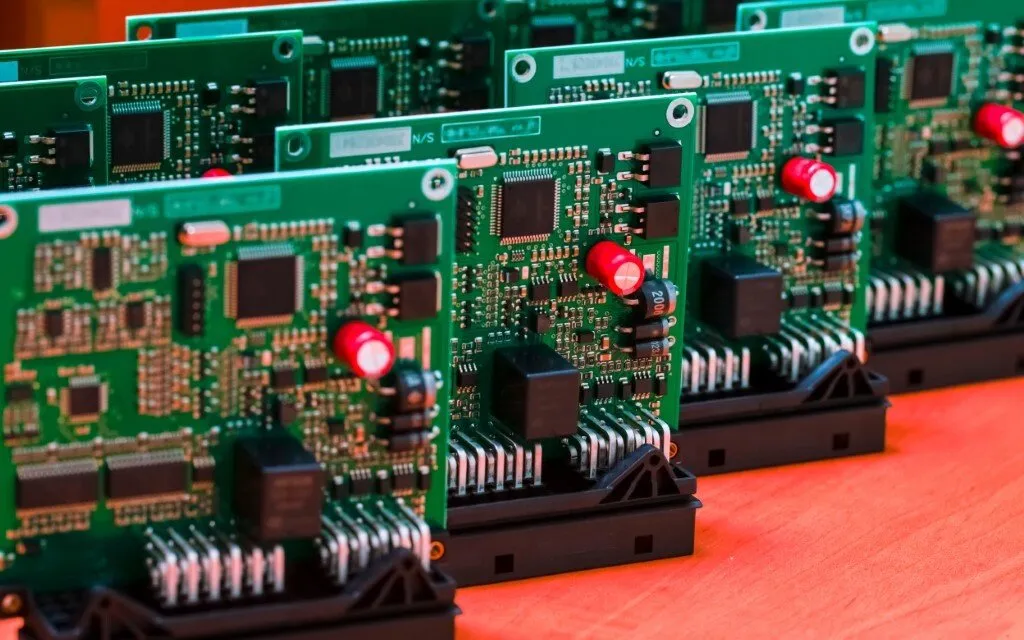

What Is PCB Turnkey? PCB Turnkey refers to a one-stop PCB solution where a single manufacturer manages the entire process—from bare PCB fabrication and electronic component procurement to assembly, testing, and logistics. Instead of coordinating multiple suppliers, customers work with one partner who takes full responsibility for quality, schedule, and delivery. At KKPCB, PCB Turnkey...

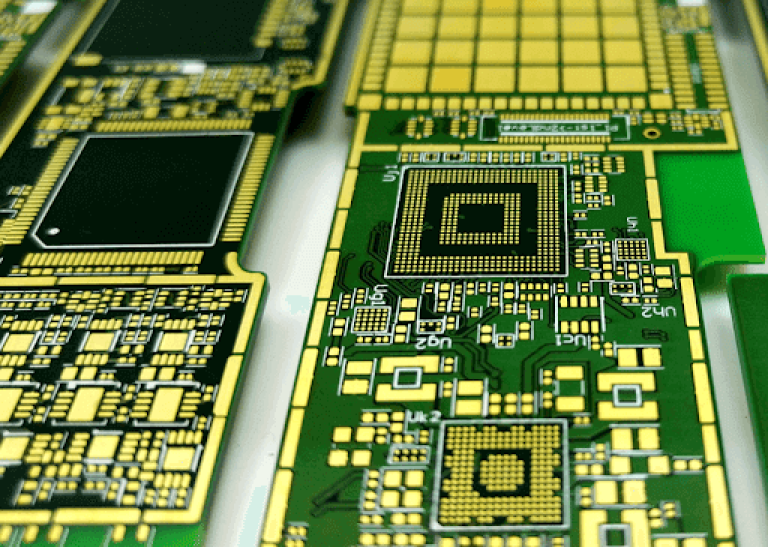

Engineering High Layer Count PCBs: Why “More Layers” Isn’t the Answer As electronic systems evolve toward higher speeds, higher integration, and smaller form factors, high layer count PCBs—typically 16 layers and above—have become standard in data centers, telecommunications, aerospace electronics, and advanced industrial systems. However, many multilayer PCBs fail not because of schematic errors, but...

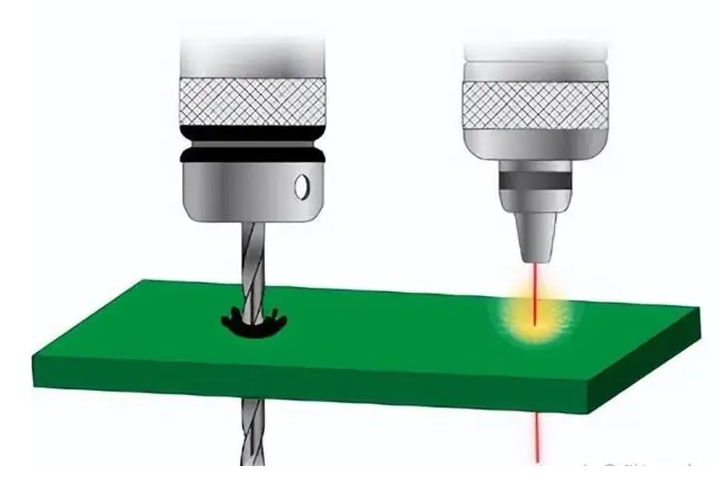

As electronic systems continue to evolve toward higher speeds, greater functionality, and reduced form factors, Buried Via PCB structures have become a critical enabler for advanced multilayer designs. By allowing interlayer connections without penetrating the outer layers, buried vias unlock higher routing density, improved signal integrity, and enhanced EMI control. However, these electrical advantages must...

As electronic systems continue to integrate higher data rates, greater power density, and tighter form factors, high layer count PCBs have become a foundational platform for modern hardware architecture. Designs exceeding 16, 20, or even 30 layers are now common in data center equipment, telecommunications infrastructure, aerospace electronics, and industrial control systems. However, increasing layer...

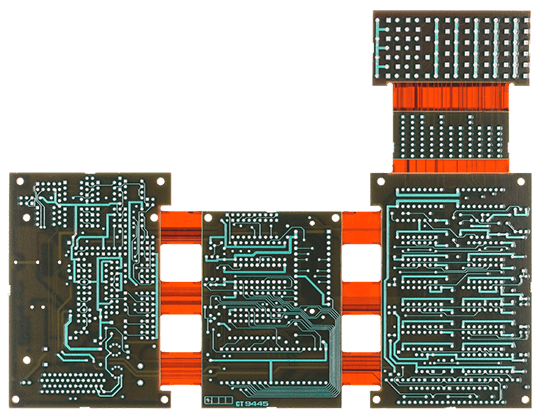

Rigid-Flex PCB as a System-Level Interconnect Architecture Rigid-Flex PCB technology integrates rigid PCB structures and flexible circuits into a single, unified interconnect platform. Compared with traditional rigid PCB assemblies connected by cables or connectors, a Rigid-Flex PCB significantly reduces interconnect interfaces while improving electrical continuity and mechanical robustness. In modern electronic systems, Rigid-Flex PCB designs...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

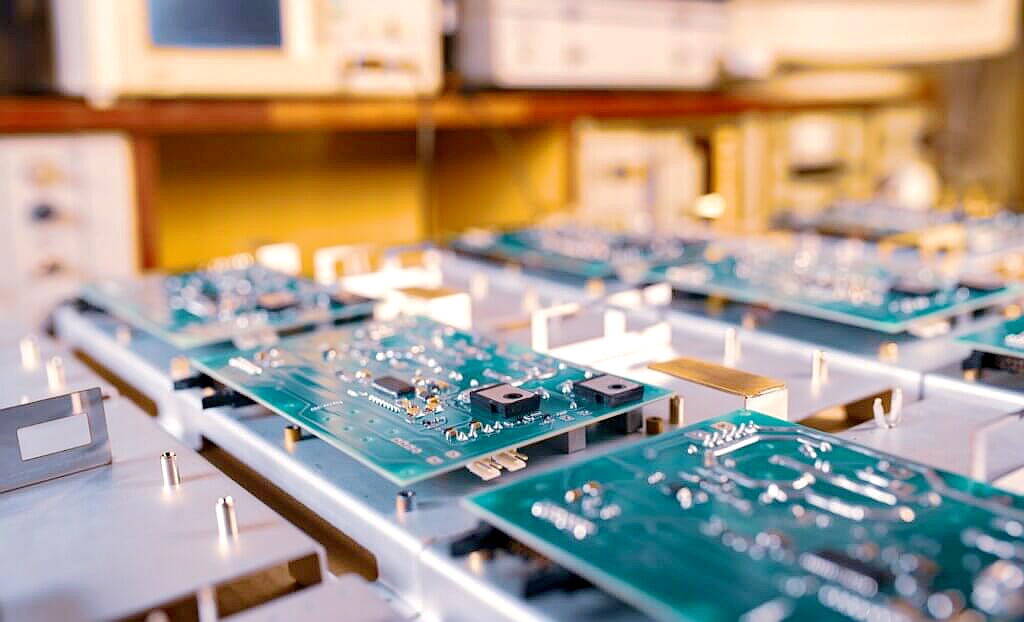

Small Batch PCB Manufacturing for High-Mix, Engineering-Driven Electronics Development

Small Batch PCB manufacturing refers to low-volume PCB production typically ranging from a few pieces to several hundred units, designed to support prototype validation, pilot runs, and early-stage product commercialization. Unlike mass production, Small Batch PCB emphasizes engineering accuracy, process flexibility, and rapid iteration over scale efficiency. For modern electronics development, Small Batch PCB is...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Turnkey Solutions for Integrated Design, Fabrication, Assembly, and Supply Chain Management

PCB Turnkey: A Complete Engineering-Driven Manufacturing Model PCB Turnkey refers to a fully integrated manufacturing solution that covers PCB fabrication, component sourcing, PCB assembly, functional testing, and logistics delivery under a single engineering-managed workflow. Unlike fragmented outsourcing models, PCB Turnkey services eliminate interface risk between suppliers and significantly improve quality consistency, lead time predictability, and...