Electrical Functions and Advantages of SMD Components SMD (Surface-Mount Device) components and SMT (Surface-Mount Technology) stickers serve the same electrical functions. However, due to their small size, SMD components offer better electrical performance. Despite these advantages, not all components are available for surface mounting. High-end processors and large connectors like BGAs (Ball Grid Arrays) and PGAs (Pin...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 10 of 75

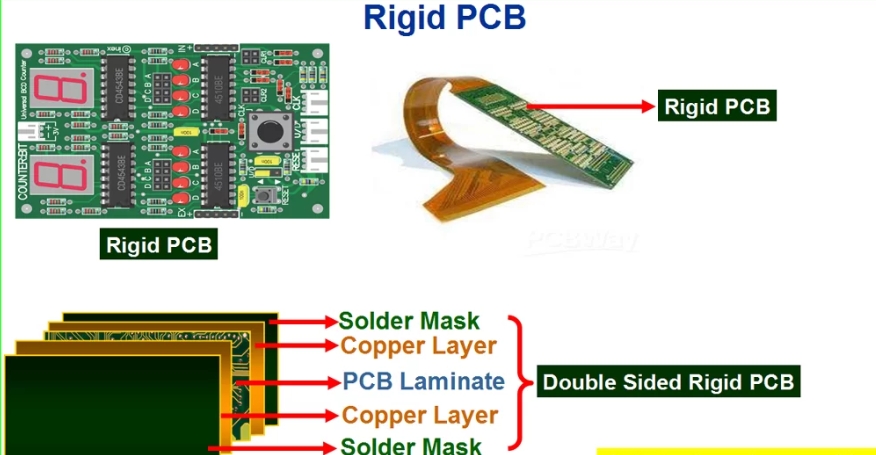

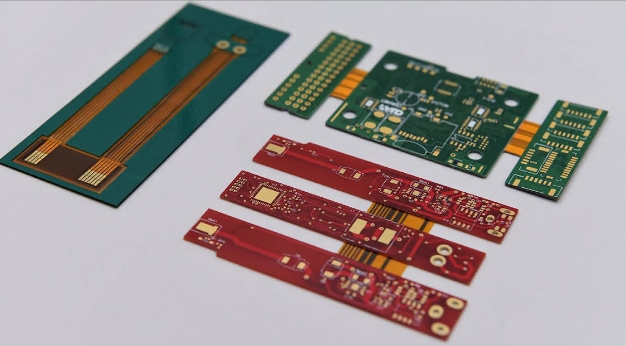

PCBs (Printed Circuit Boards) are essential in nearly every electronic device, forming the backbone of circuit design and functionality. They come in several forms, including rigid, flexible, and rigid-flex. In this article, we’ll explore the differences between rigid and flexible PCBs, their materials, costs, advantages, and disadvantages. What is a Rigid PCB? A rigid PCB is a solid,...

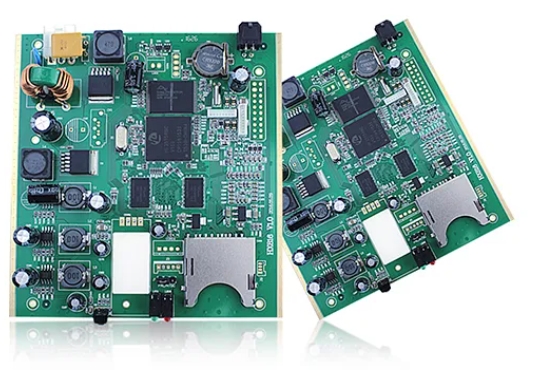

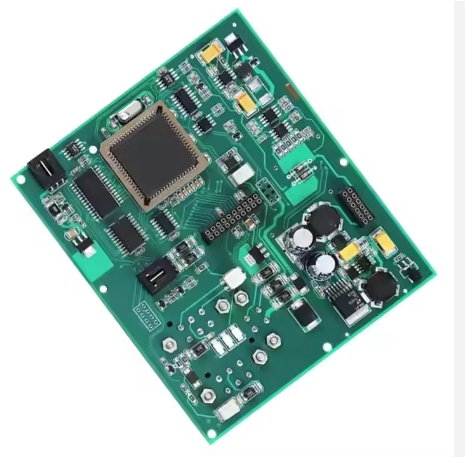

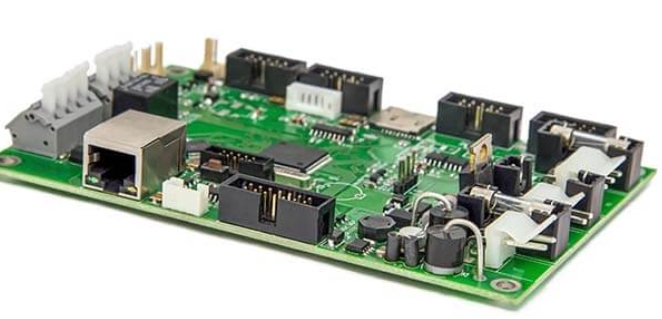

Printed Circuit Board Assembly (PCBA) refers to the process of soldering or assembling electronic components onto a PCB (Printed Circuit Board). After the components are soldered to the board, the circuit board is known as Printed Circuit Board Assembly (PCBA) or Printed Circuit Assembly (PCA). The assembly process involves a variety of techniques and tools, both manual and automated, to ensure...

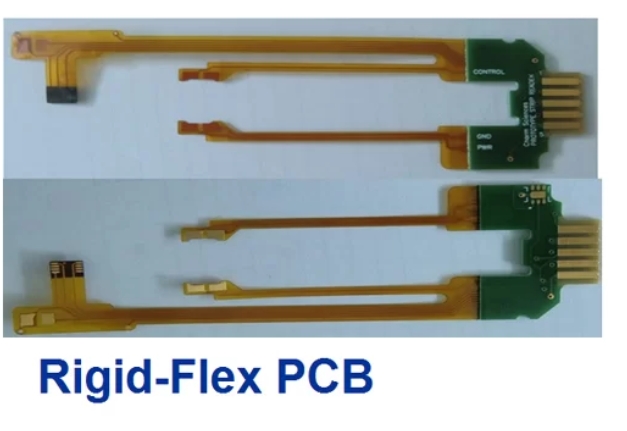

Rigid-Flex PCB is a hybrid of both rigid and flexible PCBs. In its simplest form, Rigid-Flex PCB consists of a rigid circuit board joined with a flexible circuit board, combining the advantages of both types. A Rigid-Flex PCB is made by laminating a rigid and a flexible substrate together to form a single board. Double-sided or multi-layer Rigid-Flex PCBs are interconnected by Plated Through Holes (PTH)....

Advanced PCBs are complex multi-layer printed circuit boards (PCBs) with significantly more layers than standard multi-layer boards. These advanced PCBs are crucial for high-end, high-precision electronic devices, which are typically found in industries like industrial equipment, instrumentation, automotive electronics, aviation, military applications, communication systems, complex computing, and space technology. What is Required for Advanced PCBs? The rapid advancement...

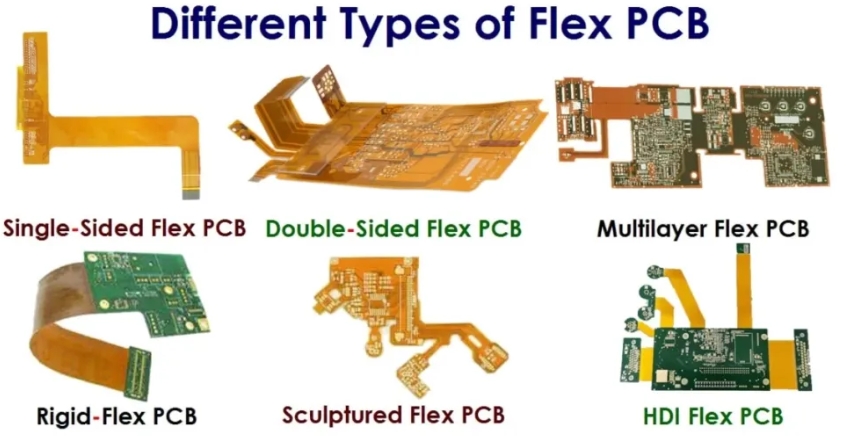

Flexible PCB or Flexible Printed Circuit Boards (FPCBs) play a crucial role in modern electronics, offering flexibility, space-saving benefits, and reliability in a wide range of applications. In this article, we’ll explore the manufacturing process of flexible PCBs, from design to assembly, and discuss their diverse applications in electronic devices. What is a Flexible PCB (FPCB)? A flexible printed circuit...

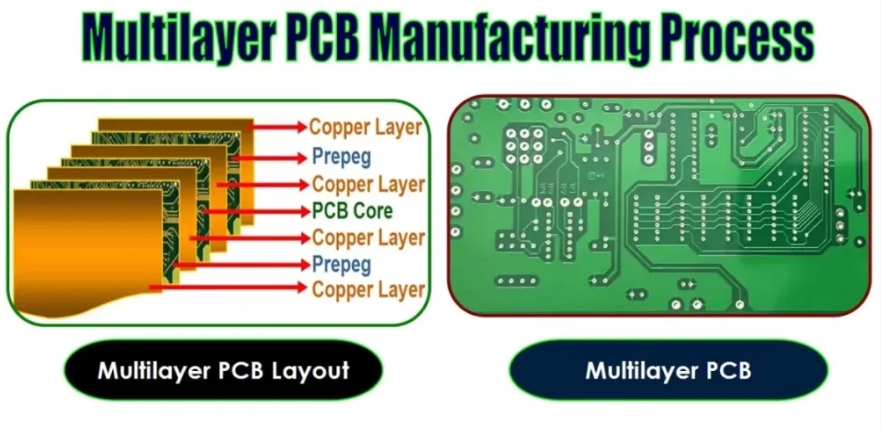

Multilayer printed circuit boards (PCBs) are widely used in modern complex electronics. These PCBs consist of multiple layers of conductive materials stacked on top of each other, enabling the design of more complex circuits with higher functionality. Such complex PCBs are used in various fields such as industrial automation, aerospace, military and medical devices, computers, and...

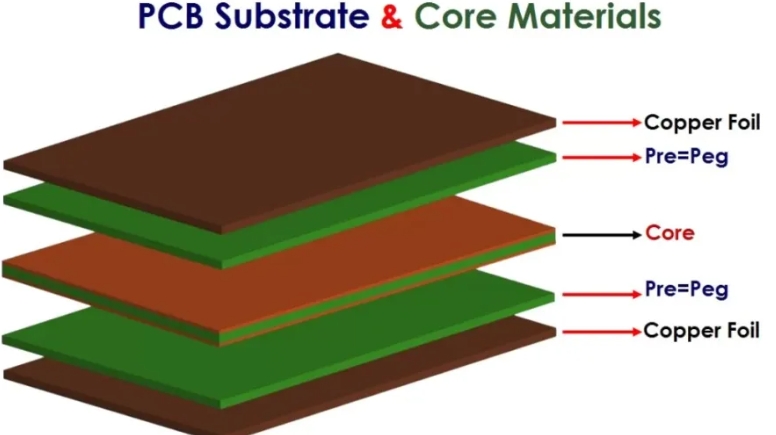

The Printed Circuit Board (PCB) is a fundamental component in all modern electronics, providing the platform for the electronic components and circuits. The performance, durability, and overall quality of a PCB are heavily influenced by the materials used for its substrate and core. This comprehensive guide explores the different types of PCB substrate and core materials, their properties, applications, and why they are...

Turnkey PCB assembly is rapidly becoming a preferred solution for businesses seeking a comprehensive, one-stop service for printed circuit board (PCB) manufacturing and assembly. In the fast-paced electronics industry, efficiency, speed, and reliability are key to maintaining competitiveness. By streamlining the entire process from design to delivery, turnkey PCB assembly services allow companies to focus on research and development...

PCB (Printed Circuit Board) substrate materials are the backbone of a PCB assembly, providing the necessary foundation for copper tracks and electronic components. The choice of PCB material plays a critical role in determining the performance, durability, and overall reliability of the PCB. These materials can be resin-based, fiberglass-based, epoxy-glass, metal-based, or flame-retardant, and they are...