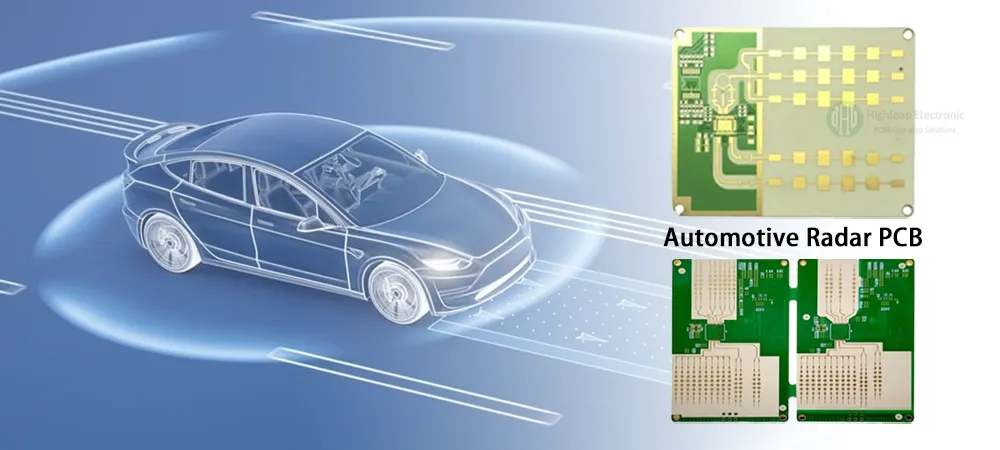

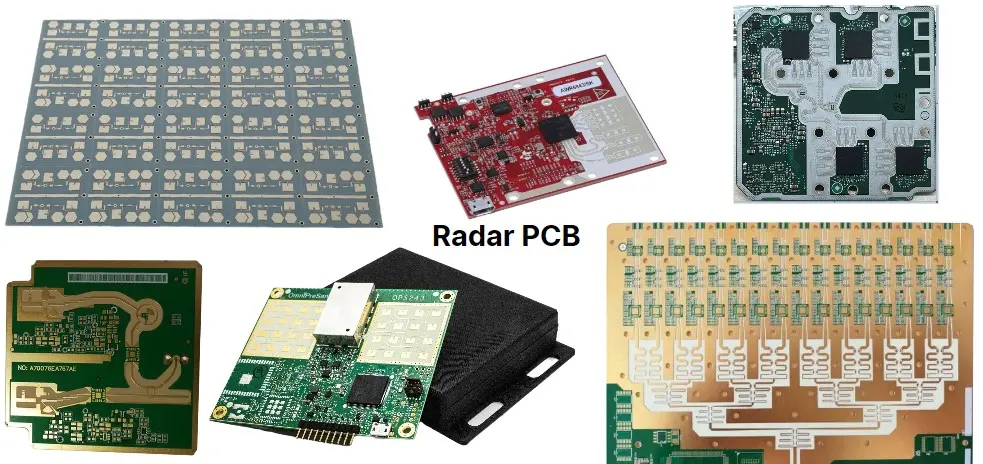

Enhancing RF Stability and Phase Accuracy Through KKPCB’s Precision Manufacturing and Dielectric Control Framework From Material Selection to Radar System Precision In modern 60 GHz radar sensor modules, used in advanced driver-assistance systems (ADAS), industrial robotics, and short-range imaging, signal integrity and impedance control directly determine detection accuracy and angular resolution.Even minor inconsistencies in...

HomeAuthor

kkpcb02 - KKPCB - Page 5 of 7

Achieving High-Frequency Reliability and Efficient Heat Dissipation Through KKPCB’s Hybrid Lamination Platform From Material Performance to System-Level Efficiency In industrial mmWave transceiver modules operating from 28 to 81 GHz, engineers face a dual challenge: maintaining signal integrity across multilayer stackups while managing localized power density and heat accumulation.Traditional FR-4 or mid-grade PTFE composites...

Ensuring Low-Loss Transmission and Thermal Reliability Through KKPCB’s Duroid 5880 PCB Engineering 1. Why Duroid 5880 PCB Defines RF Power Amplifier Reliability In modern RF Power Amplifier systems used in defense radar, satellite uplink transmitters, and 5G mmWave base stations,the Duroid 5880 PCB provides exceptional dielectric stability and low-loss performance for power and...

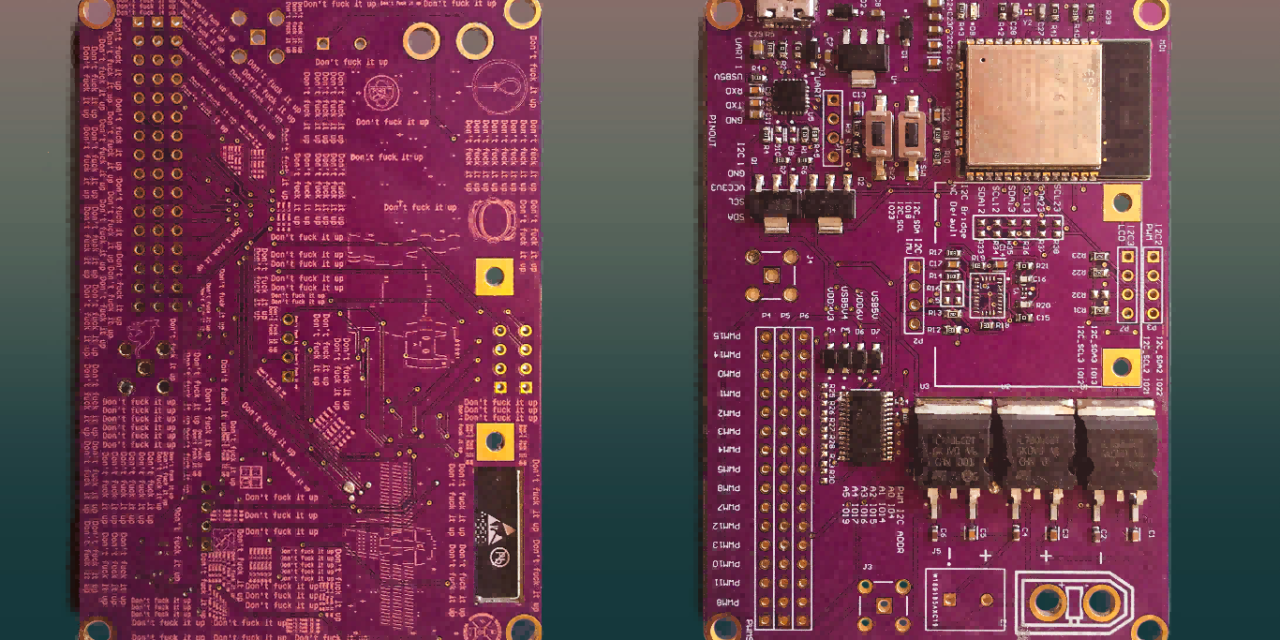

Achieving Traceable Phase Accuracy and Long-Term Measurement Repeatability Through KKPCB’s RF Metrology Manufacturing Framework 1. Context — Why Measurement Stability Defines Modern RF Metrology In advanced calibration systems, such as Vector Network Analyzers (VNA), antenna test chambers, and satellite link verification benches, the PCB substrate becomes the reference plane of accuracy.Even a 0.05 variation...

Ensuring High-Frequency Stability and Heat Dissipation Integrity Through KKPCB’s Advanced RF Lamination Framework 1. Introduction — The Hidden Heat Challenge in Aerospace RF Systems As defense radar modules and satellite tracking systems migrate toward Ka- and W-band frequencies, the thermal load within power amplifier and antenna front-end PCBs grows dramatically. At these...

Engineering Ultra-Low-Loss RF Path Consistency Through KKPCB’s Precision Manufacturing Framework From Material Purity to mmWave Signal Integrity As mmWave and phased array technologies push operational frequencies beyond 40–110 GHz, signal integrity becomes the decisive factor defining array accuracy, beam steering precision, and system reliability. Rogers Duroid 5880, known for its ultra-low dielectric...

Ensuring Long-Term RF Accuracy and Material Safety Through KKPCB’s Advanced PTFE Processing and Bio-Compatible Validation In medical imaging, wearable diagnostics, and precision industrial sensing, RF signal stability and biocompatibility are not just performance indicators — they are safety-critical.A 0.1 dB drift in an RF ablation system can alter treatment precision; a 0.05 dielectric shift...

Enabling Ultra-Stable Beamforming Through KKPCB’s RF Engineering and PTFE Process Expertise In satellite payloads, deep-space probes, and phased-array ground stations, antenna array linearity and phase coherence directly determine link stability and pointing accuracy.At Ka-band (26–40 GHz) and beyond, a 1° phase drift or 0.1 dB amplitude variation can distort beam direction, degrade gain, and...

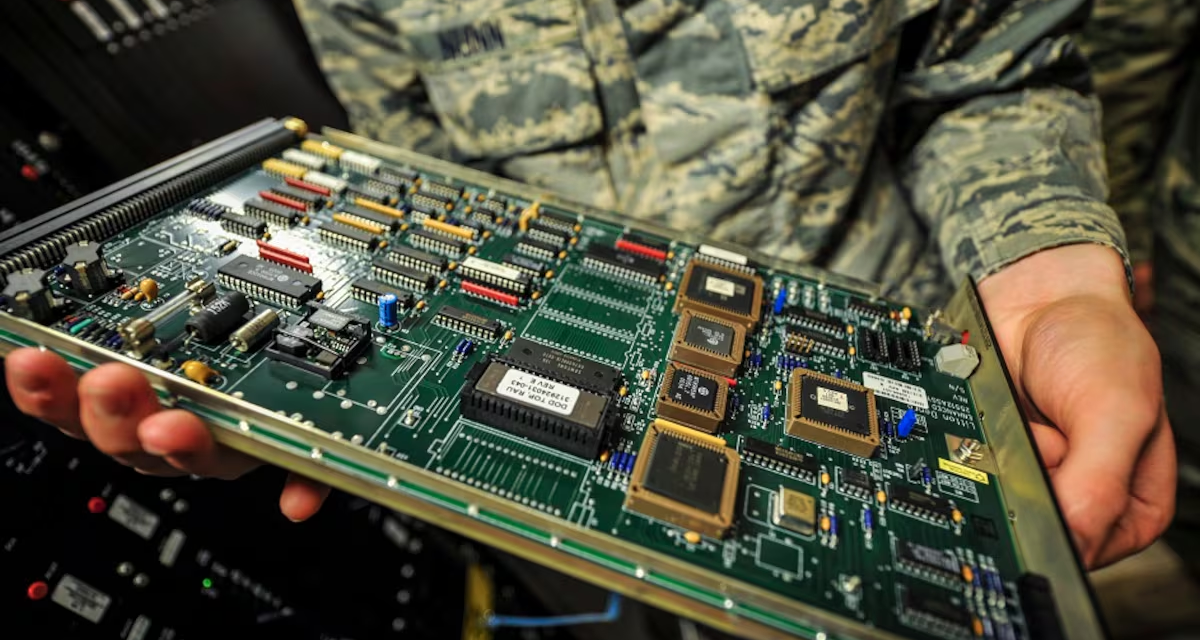

KKPCB’s Advanced RF Thermal Design for Power-Dense Defense Applications In modern military radar and electronic warfare (EW) systems, the migration toward high-power mmWave front-end modules introduces dual challenges: managing thermal dissipation and ensuring power integrity across densely packed RF chains. At frequencies exceeding 40–94 GHz, even minute impedance shifts or localized heating on the...

Ensuring Phase-Consistent Measurement Accuracy Through KKPCB’s Ultra-Low-Loss RF Manufacturing Platform As mmWave calibration and test systems advance into the 40–110 GHz domain, every transmission line, connector, and RO5880 PCB trace within the measurement chain directly influences phase linearity and amplitude accuracy.Even a minor 0.1 dB loss variation or 1° phase shift can distort calibration...