As 5G technology continues to evolve, 5G communication modules are becoming more compact, integrated, and performance-sensitive. 5G module PCB assembly plays a critical role in ensuring signal integrity, RF stability, and long-term reliability. Compared with conventional PCBA, 5G module assembly requires higher precision, stricter process control, and advanced testing capability. This article outlines the key...

HomeTag

SMT Assembly - KKPCB

As 5G technology drives faster data rates, lower latency, and higher bandwidth, the complexity of 5G modules continues to increase. A 5G module integrates RF front-end circuits, baseband processing, power management, and high-speed interfaces into a compact design. 5G module PCB assembly plays a critical role in ensuring stable RF performance, signal integrity, and long-term...

As 5G technology continues to expand across telecommunications, IoT, and industrial applications, the demand for reliable 5G module PCB assembly has grown rapidly. 5G modules integrate high-speed digital circuits, RF front-end components, and antennas into compact form factors, making PCB assembly quality critical to overall system performance. This article explores the key requirements, challenges, and...

PCB Turnkey Services: A Complete One-Stop Solution for PCB Manufacturing and Assembly In today’s fast-paced electronics industry, reducing supply chain complexity and accelerating time to market are critical for success. PCB Turnkey services provide a complete, one-stop solution that covers every stage of electronics production—from PCB fabrication and component sourcing to assembly, testing, and final...

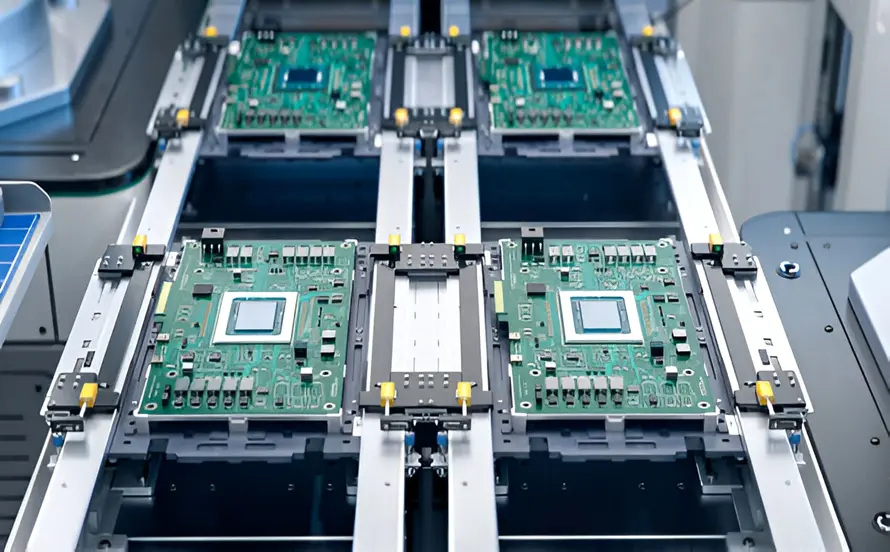

Applications of Factory Automation in PCB Manufacturing As electronic devices become more compact, powerful, and multifunctional, printed circuit boards (PCBs) must meet increasingly complex performance and reliability requirements. To support this evolution, factory automation has become a fundamental pillar of modern PCB manufacturing. Automated systems not only accelerate production but also improve precision, ensure repeatability,...

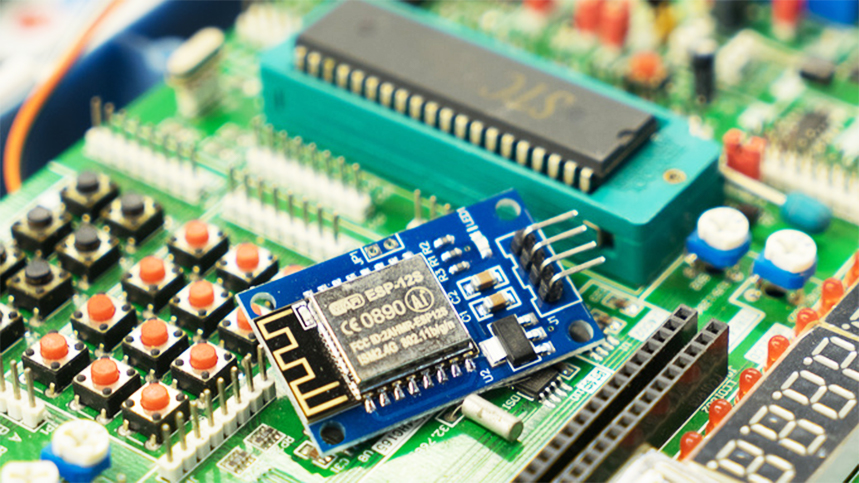

SMT, the short form of Surface Mount Technology, a type of PCB (Printed Circuit Board) assembly technology, refers to the technology of getting components directly soldered onto the surface of PCB to replace THT (Through-Hole Technology) that has to make use of drilling holes. This article will discuss the essential elements of SMT assembly so that readers are able...

Electronic devices have transformed our lives, from smartphones to electric vehicles, all thanks to continuous innovation and advancements in technology. At the heart of these devices are printed circuit boards (PCBs) that are meticulously manufactured, assembled, and packaged to deliver the final products we rely on. This article explores the PCB Surface Mount Technology (SMT) assembly process,...

When it comes to assembling Printed Circuit Boards (PCBs), there are two primary technologies: Surface Mount Technology (SMT) assembly and Through-Hole Technology (PTH) assembly. Understanding their differences, advantages, and disadvantages is crucial for selecting the best option for your PCB-based project. This guide by Viasion experts provides a comprehensive comparison to help you make an informed decision. What...

Learn the differences between flux and solder paste in PCB soldering. Understand their composition, functions, and applications for hand soldering, wave soldering, and SMT assembly. Ensure high-quality, reliable solder joints with KKPCB expertise.