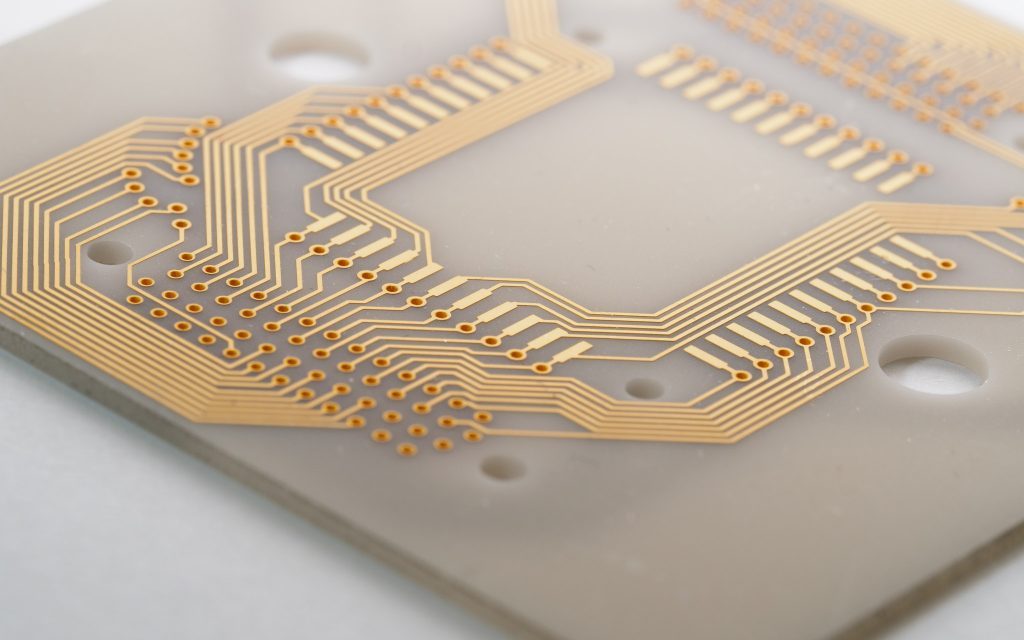

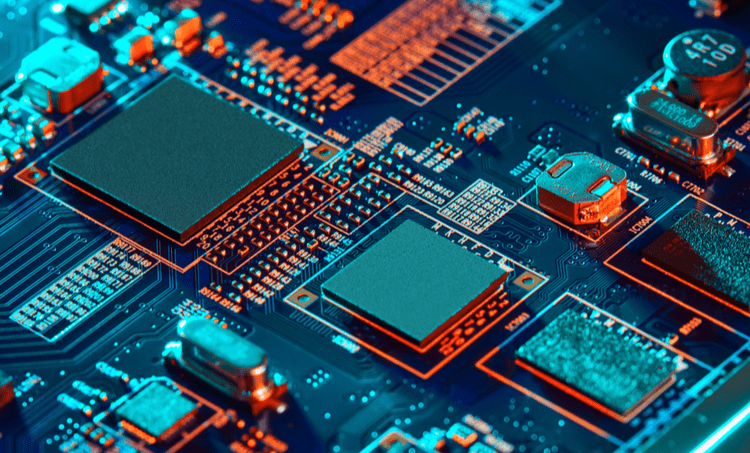

An Aluminum Nitride PCB (AlN PCB) is a ceramic-based circuit substrate engineered for electronic systems that demand exceptional thermal conductivity, electrical insulation, and dimensional stability under high power density and elevated temperature conditions. In power electronics and high-reliability applications, material selection is not a secondary decision—it defines system performance limits. Material-driven Aluminum Nitride PCB design...

HomeTag

Power Electronics PCB - KKPCB

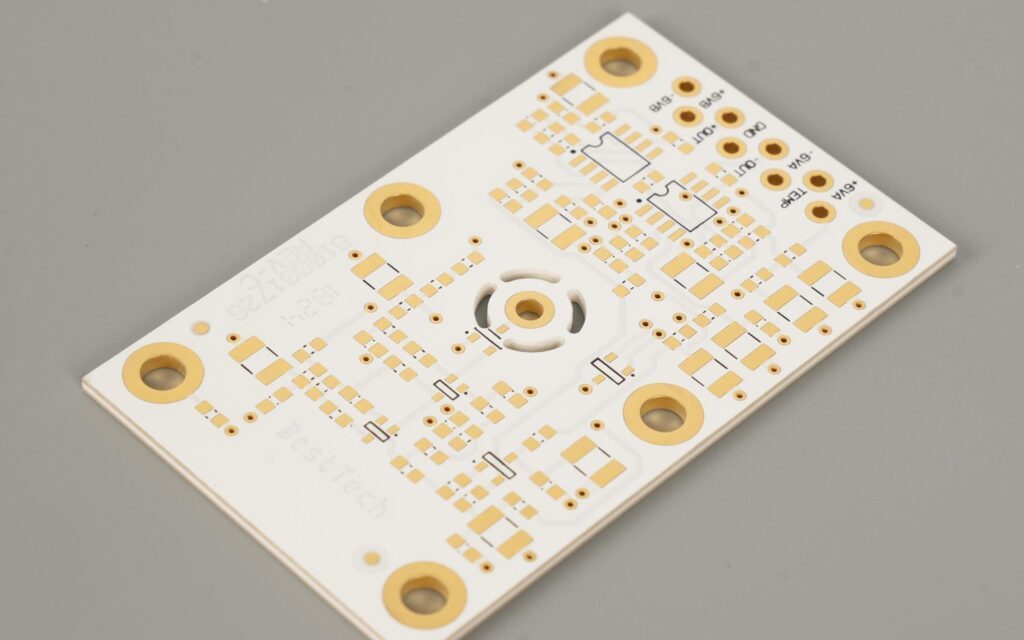

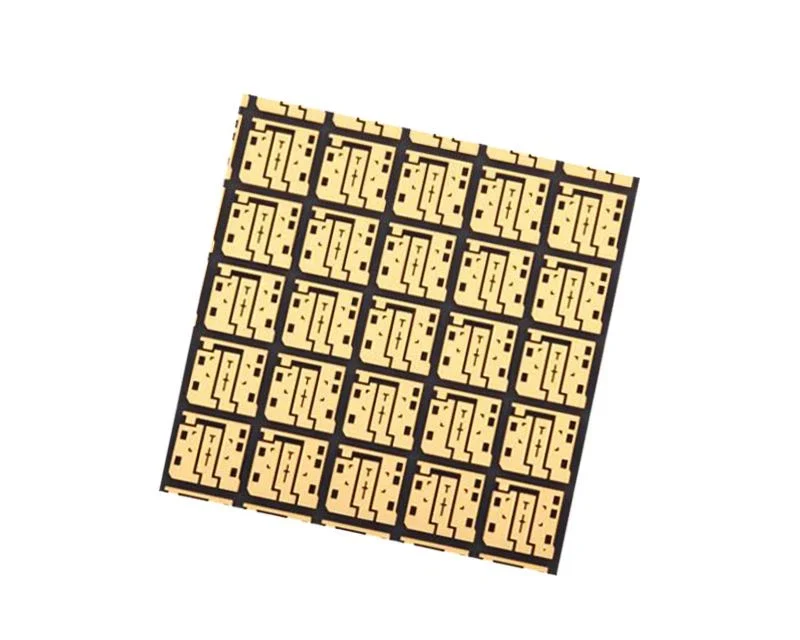

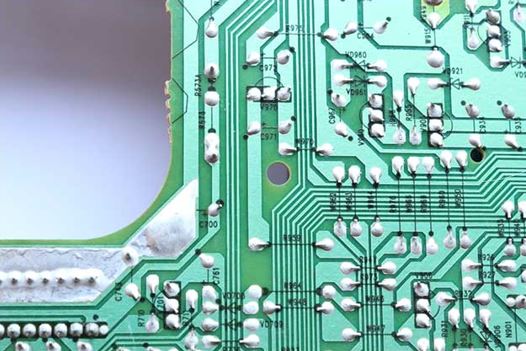

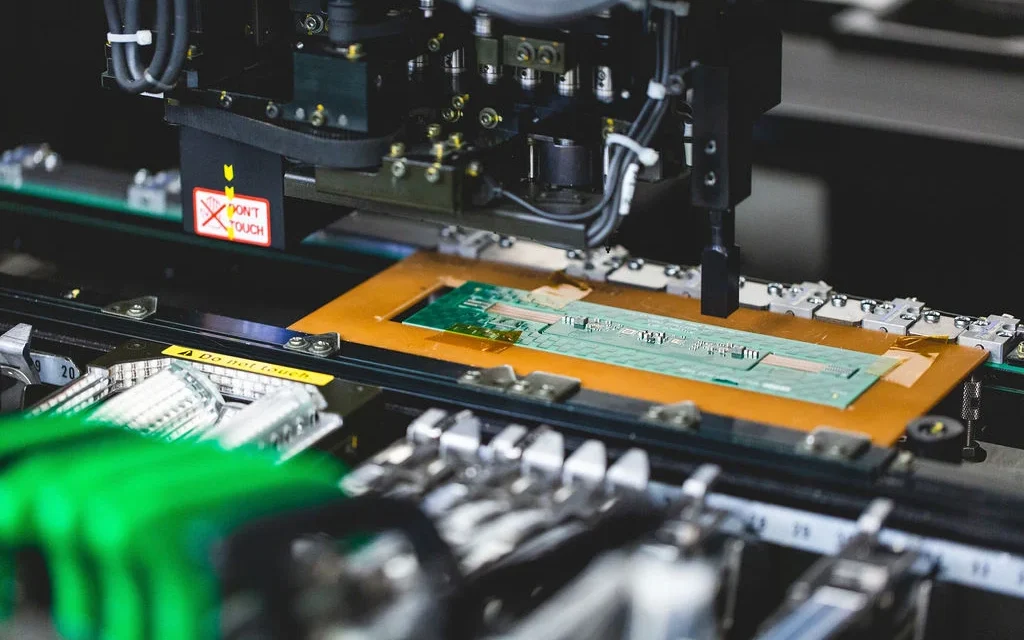

A Ceramic PCB is a high-performance circuit substrate engineered for applications that demand excellent thermal conductivity, electrical insulation, and long-term reliability under harsh operating conditions. Unlike organic PCB materials such as FR-4 or PTFE, ceramic PCB substrates are inorganic, enabling stable electrical and mechanical performance at elevated temperatures and high power densities. Ceramic PCB technology...

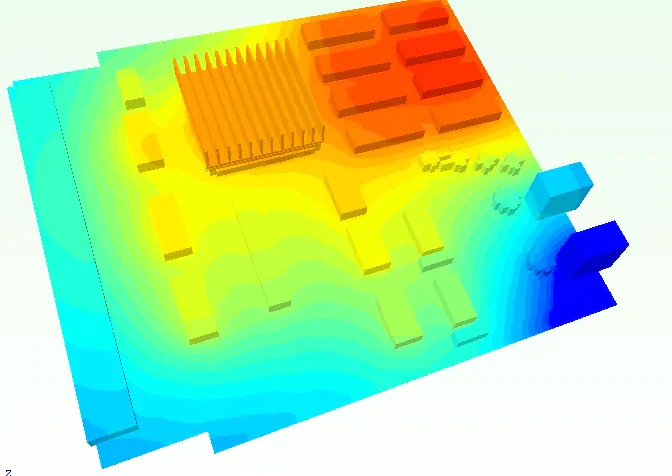

As modern electronics continue to evolve toward higher power density, smaller packaging, and harsher operating environments, thermal performance has become one of the most important factors in PCB material selection. In applications such as EV power modules, IGBT and MOSFET power stages, SiC/GaN devices, and high brightness LED modules, traditional FR-4 PCBs often cannot provide...

What Is a High Current PCB? A High Current PCB is a printed circuit board specifically engineered to carry and distribute large electrical currents safely and efficiently. Unlike standard PCBs, high current PCBs utilize heavy copper layers, wide trace designs, and optimized thermal management to minimize power loss, prevent overheating, and ensure long-term reliability. High...

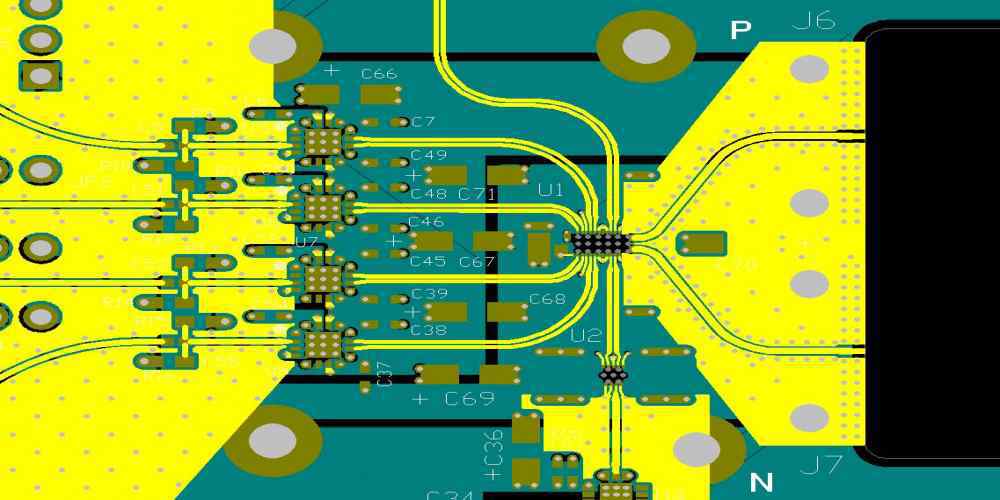

What Is a Power Integrity PCB? A Power Integrity (PI) PCB is a specialized printed circuit board designed to maintain stable voltage, minimize power noise, and ensure consistent current delivery across all components in high-speed, high-frequency, and high-density electronic systems. In modern electronics, poor power integrity can lead to signal errors, timing instability, and even...

What Is a High Current PCB? A High Current PCB is specifically designed to safely carry and distribute large electrical currents without overheating, voltage drop, or reliability failure. Unlike standard PCBs, a high current PCB focuses on low resistance conductor design, thick copper layers, and enhanced thermal management to ensure stable performance under continuous or...

A Thermal Management PCB is a specialized printed circuit board designed to control, spread, and dissipate heat generated by electronic components. As modern electronic devices operate at higher power levels, higher frequencies, and increased component density, effective thermal management has become a critical factor in ensuring performance stability, reliability, and product lifespan. By integrating advanced...

A Thermal Management PCB is a specialized printed circuit board designed to effectively manage heat generated by high-power components. As electronic devices become more compact and operate at higher currents and voltages, efficient heat dissipation is critical to maintain performance, prevent component failure, and ensure long-term reliability. These PCBs are widely used in power electronics,...

Engineering Context: Why High TG PCB Is Critical in Modern Electronics As electronic systems continue to push toward higher power density, faster signal speeds, and harsher operating environments, conventional PCB materials increasingly become a reliability bottleneck. Excessive heat, repeated thermal cycling, and dense component placement place enormous stress on standard laminates, often leading to warpage,...

High TG PCB technology has become a cornerstone for high-temperature, high-power, and long-duty-cycle electronic systems. As devices shrink, current density rises, and thermal loads increase, traditional FR-4 can no longer maintain stability. This is where High TG PCB materials—TG170, TG180, and beyond—deliver the thermal robustness and dimensional stability required for demanding environments. High TG (Glass...