With the rapid advancement of high-frequency electronics, modern RF and microwave systems demand PCBs with ultra-low loss, stable dielectric properties, and controlled impedance performance. Applications such as 5G wireless communication, satellite systems, radar, high-frequency RF front-end modules, and microwave circuits require materials that maintain signal integrity at GHz frequencies. Duroid PCB is a PTFE-based high-frequency...

HomeTag

PCB manufacturing - KKPCB

As electronic devices become faster and more complex, maintaining the quality of electrical signals on a PCB is critical. Signal Integrity PCBs are designed to preserve signal quality, minimize noise, and reduce data errors in high-speed circuits. Proper design and manufacturing of these boards are essential for reliable high-performance electronics, from telecommunications and computing to...

Modern electronics often require boards capable of handling high currents safely and efficiently. High Current PCBs are specially designed to manage large amounts of electrical current while maintaining thermal stability, signal integrity, and mechanical reliability. These PCBs are widely used in power electronics, automotive systems, industrial machinery, and energy storage applications. What is a High...

In today’s rapidly evolving electronics market, devices are becoming smaller, faster, and more complex. To meet these demands, Microvia PCBs have become a critical solution in HDI PCB and high-speed PCB design. Microvias are extremely small vias that create precise interlayer connections, allowing for high-density routing, improved signal integrity, and reliable performance in modern electronic...

Between prototyping and mass production, semiconductor test development requires a flexible manufacturing stage to validate design stability and manufacturing consistency. Small batch ATE PCBs bridge this critical gap by enabling controlled, repeatable builds for engineering validation and pilot testing in ATE environments. Small batch ATE PCB manufacturing ensures design maturity before full-scale production. What Is...

In a competitive electronics market, sourcing printed circuit boards from a PCB supplier direct—a factory-level manufacturer rather than an intermediary—provides clear advantages in price transparency, communication efficiency, quality control, and production reliability. A true PCB supplier direct partner enables engineers and procurement teams to access direct factory pricing, faster engineering feedback, and high-performance PCB manufacturing...

In today’s global electronics supply chain, many engineers and procurement teams prefer to source printed circuit boards directly from a PCB supplier direct—a factory-level manufacturer that eliminates intermediaries and delivers transparent pricing, faster lead times, and tighter quality control. A true PCB supplier direct partner provides direct access to PCB manufacturing expertise, supports rapid prototyping,...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Factory Direct: Cost-Effective, Transparent, and Reliable PCB Manufacturing from the Source

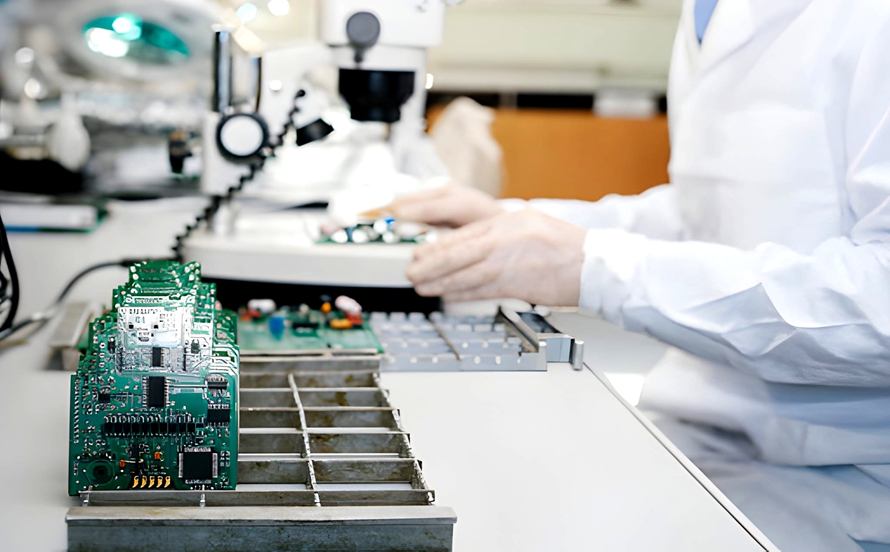

Choosing PCB factory direct manufacturing is one of the most effective ways for electronics companies to reduce cost, improve communication, and ensure consistent quality. By sourcing PCBs directly from the factory, customers eliminate intermediaries and gain full control over pricing, lead time, and manufacturing processes. For prototype development, small batch orders, and mass production, PCB...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Factory Direct: Cost-Effective, Reliable, and Transparent PCB Manufacturing from the Source

Choosing PCB factory direct manufacturing has become the preferred sourcing model for global electronics companies seeking lower cost, faster response, and higher quality control. By working directly with a PCB factory, customers eliminate intermediaries and gain full transparency over pricing, lead time, and manufacturing processes. PCB factory direct sourcing is ideal for PCB prototypes, small...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

PCB Price Request: How to Get a Fast, Accurate, and Competitive PCB Quotation

Submitting a clear and complete PCB price request is the most effective way to receive an accurate quotation, reduce communication time, and speed up PCB production. Whether you are ordering PCB prototypes, small batch runs, or mass production, the quality of your price request directly affects cost, lead time, and manufacturing feasibility. This guide explains...