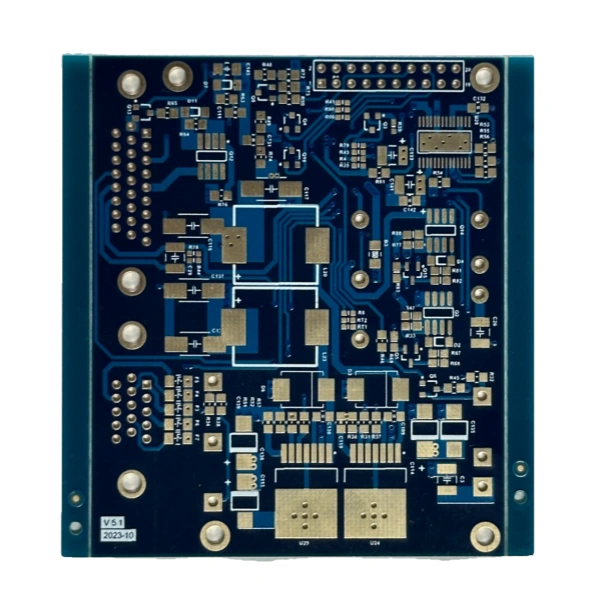

As electronic devices become smaller, faster, and more complex, traditional PCB technologies often reach their physical limits. HDI PCB (High Density Interconnect PCB) technology was developed to overcome these challenges by enabling higher wiring density, finer geometries, and improved electrical performance. A professionally manufactured HDI PCB is a key enabler for modern consumer electronics, communication...

HomeTag

multilayer PCB - KKPCB

High Pin Count PCB: Enabling Dense Interconnection for Advanced Electronic and Semiconductor Systems

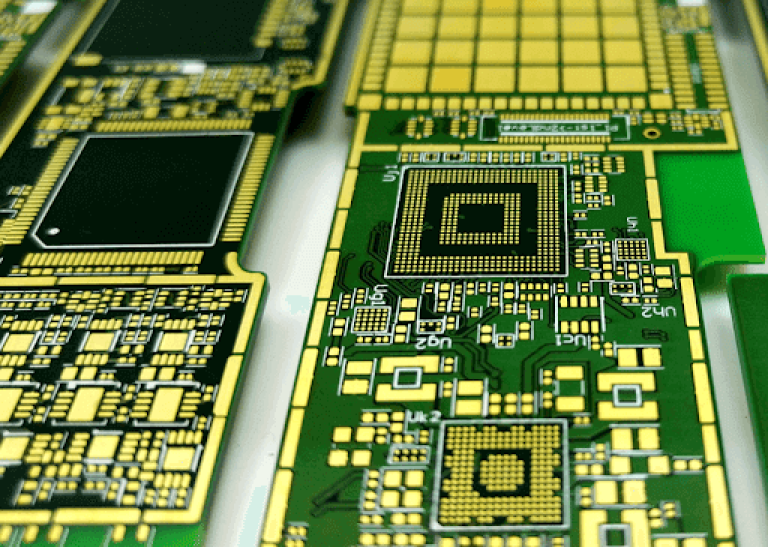

As electronic systems continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections continues to rise. The High Pin Count PCB is specifically engineered to manage thousands of interconnections while maintaining electrical integrity, mechanical reliability, and manufacturability. A professionally designed High Pin Count PCB is essential for modern...

As electronic devices continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections has increased dramatically. The high pin count PCB is specifically engineered to support dense interconnect requirements while maintaining stable electrical and mechanical performance. From semiconductor testing to high-speed communication systems, a professionally manufactured high pin...

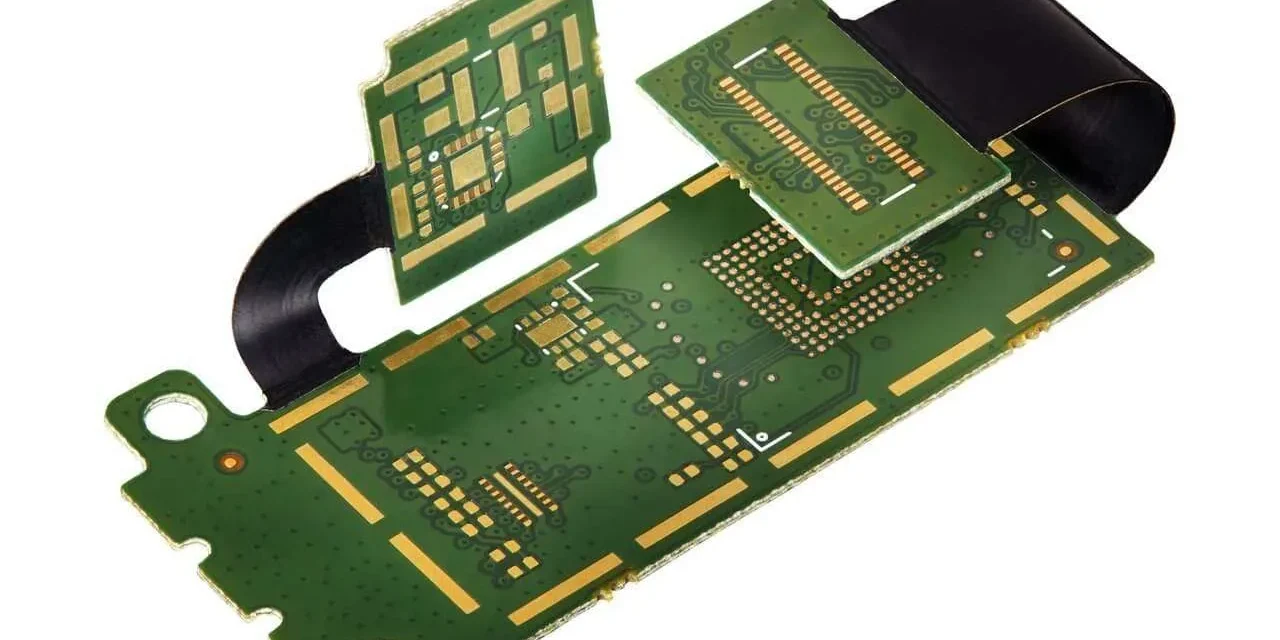

Multilayer Rigid-Flex PCB Manufacturer: Advanced Solutions for High-Density and Flexible Electronics

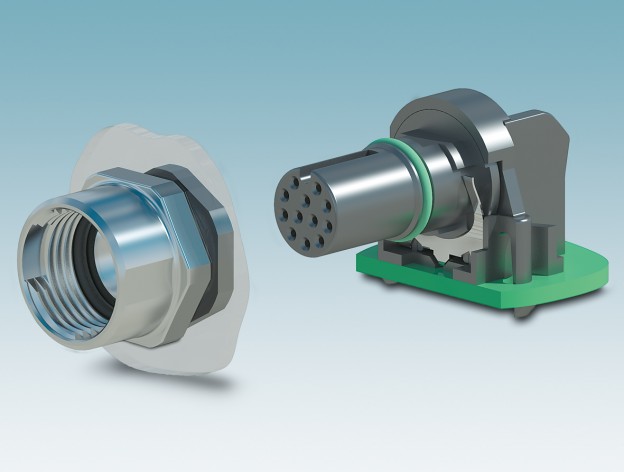

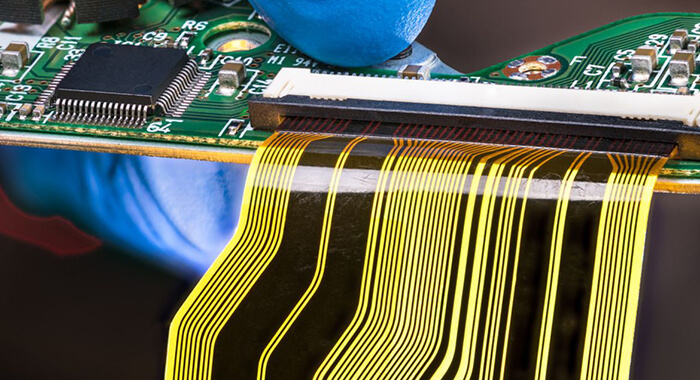

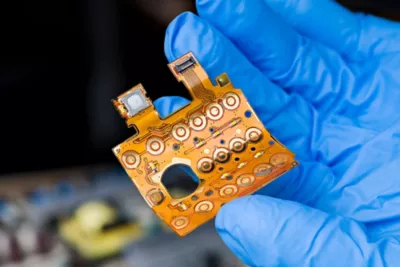

Modern electronics increasingly require compact, lightweight, and mechanically flexible designs. Multilayer rigid-flex PCB manufacturers provide integrated solutions that combine rigid PCB sections with flexible circuits, enabling reliable interconnection and high-density packaging in advanced electronic systems. From wearable devices to aerospace and automotive electronics, multilayer rigid-flex PCBs offer durability, signal integrity, and design flexibility that conventional...

As electronic products become smaller, lighter, and more complex, the demand for integrated and space-saving interconnect solutions continues to grow. A professional multilayer rigid-flex PCB manufacturer provides advanced manufacturing solutions that combine the mechanical stability of rigid PCBs with the flexibility of flex circuits. Multilayer rigid-flex PCBs enable compact design, improved reliability, and reduced interconnection...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Multilayer Rigid-Flex PCB Manufacturer: Advanced Solutions for Compact and High-Reliability Electronics

As electronic products become smaller, lighter, and more functionally integrated, traditional rigid PCBs and cable interconnects often fail to meet modern design requirements. Multilayer rigid-flex PCBs combine rigid and flexible circuits into a single structure, enabling compact layouts, improved reliability, and enhanced electrical performance. Working with an experienced multilayer rigid-flex PCB manufacturer is essential to...

In today’s fast-paced electronics industry, rapid product validation and frequent design iterations are essential.small batch PCBmanufacturing provides an ideal solution for startups, R&D teams, and engineering groups that require high-quality PCBs without committing to large production volumes. This article explores what small batch PCB manufacturing is, why it matters, and how it supports efficient product...

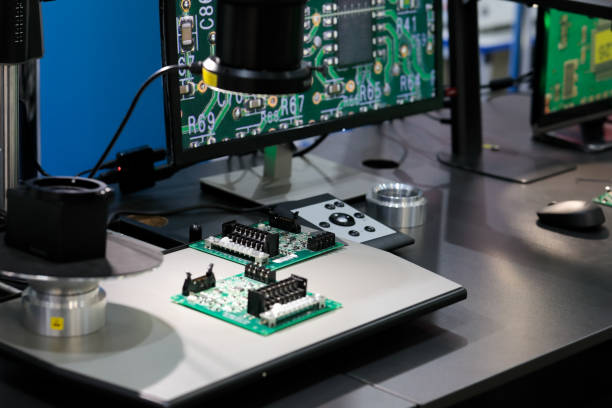

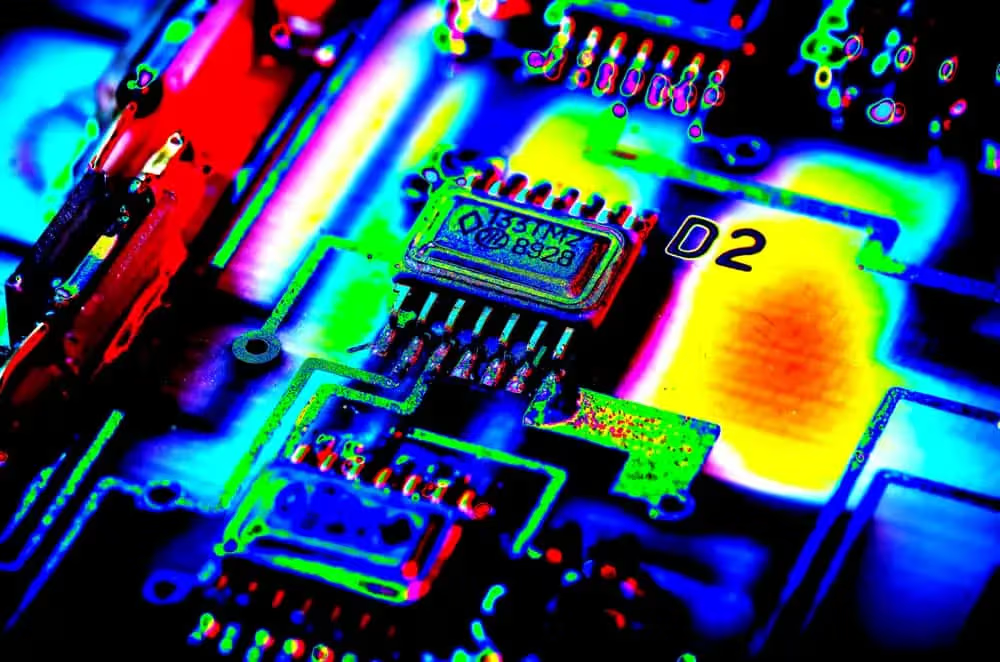

Key Manufacturing Factors That Affect Controlled Impedance PCB Accuracy In today’s high-speed electronics market, Controlled Impedance PCB manufacturing has become a fundamental requirement for ensuring excellent signal integrity and stable electrical performance. As operating frequencies and data transmission speeds continue to rise, even minor impedance deviations in a controlled impedance PCB can result in signal...

Engineering High Layer Count PCBs: Why “More Layers” Isn’t the Answer As electronic systems evolve toward higher speeds, higher integration, and smaller form factors, high layer count PCBs—typically 16 layers and above—have become standard in data centers, telecommunications, aerospace electronics, and advanced industrial systems. However, many multilayer PCBs fail not because of schematic errors, but...

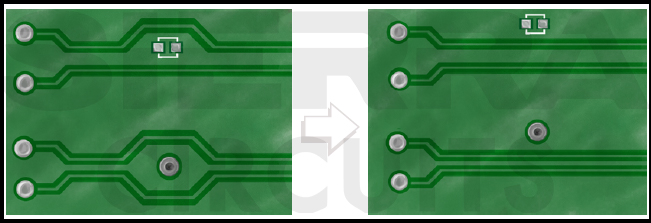

As electronic systems continue to evolve toward higher speeds, greater functionality, and reduced form factors, Buried Via PCB structures have become a critical enabler for advanced multilayer designs. By allowing interlayer connections without penetrating the outer layers, buried vias unlock higher routing density, improved signal integrity, and enhanced EMI control. However, these electrical advantages must...