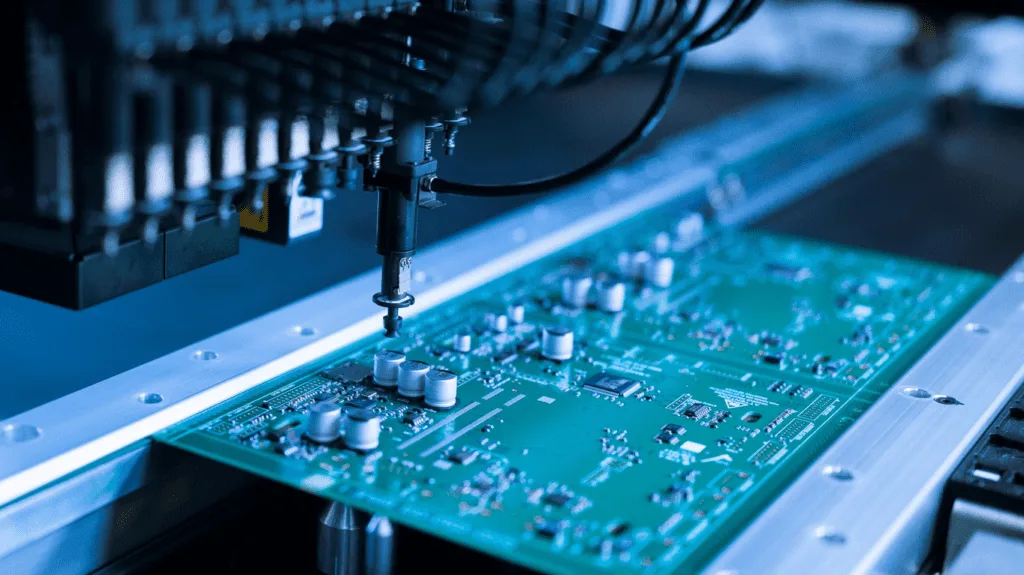

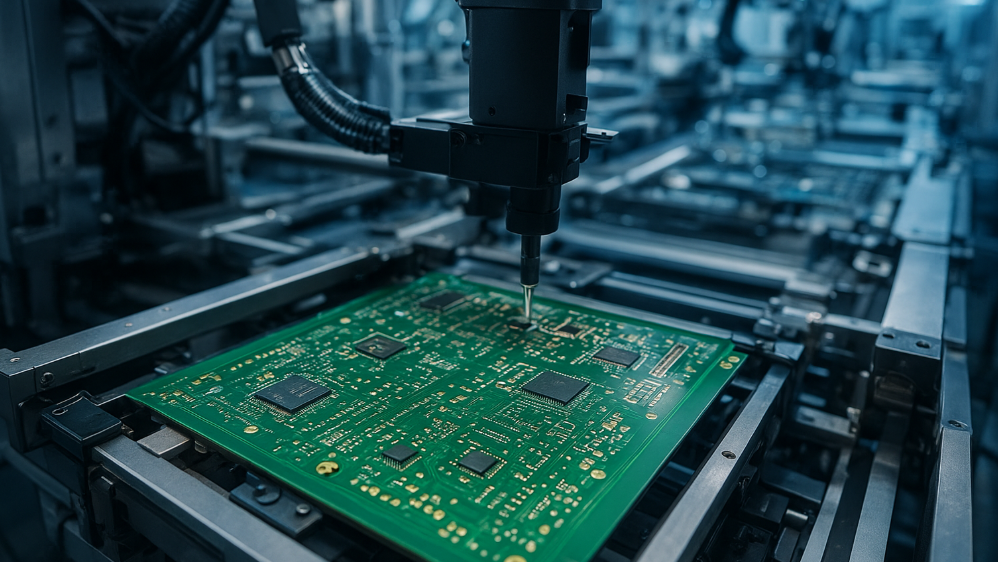

Introduction: Why Industrial Automation PCB Matters in Modern Manufacturing As factories advance toward full digitalization, the Industrial Automation PCB becomes the central hardware platform enabling control, monitoring, power management, robotics coordination, and real-time data acquisition.Unlike consumer electronics, an Industrial Automation PCB must operate reliably under harsh conditions—temperature extremes, vibration, electrical noise, humidity, and continuous 24/7...

HomeTag

industrial automation PCB - KKPCB

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB Assembly (PCBA)PCB DesignPCB ManufacturingPCB Materials

Smart Factory PCB Engineering for IIoT Intelligence, Autonomous Production, and Next-Generation Industrial Control

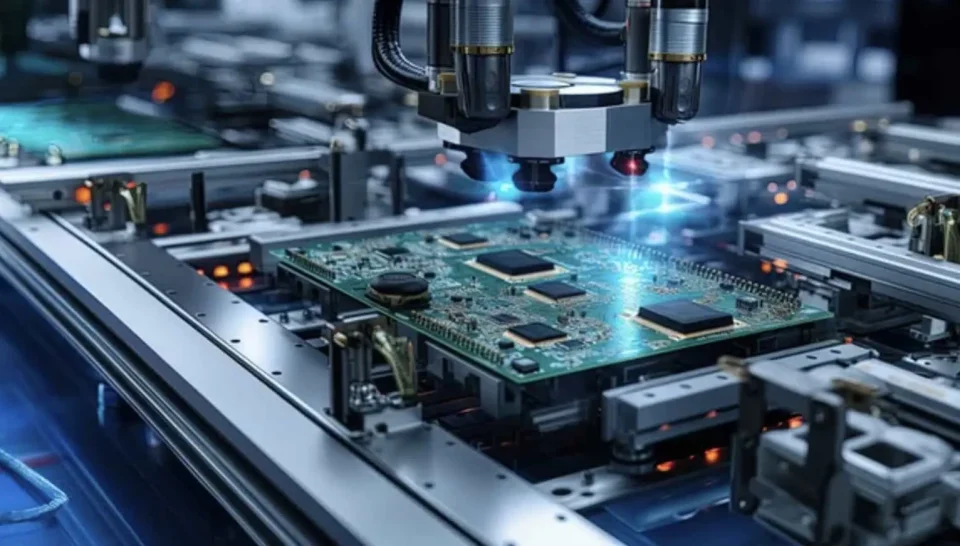

As global manufacturing transitions into fully connected, autonomous, data-driven ecosystems, the Smart Factory PCB has become the central hardware platform enabling real-time monitoring, predictive analytics, robotic coordination, and closed-loop industrial automation. Every intelligent machine, from PLC control modules to AMR robots and sensor gateways, relies on a high-reliability Smart Factory PCB to operate with precision...

In the accelerating era of Industry 4.0 and intelligent manufacturing, the Industrial Automation PCB has become the fundamental hardware platform enabling stable operation of automated production lines, robotic motion systems, IIoT equipment, and mission-critical industrial controllers. A high-quality Industrial Automation PCB determines whether robotic actuators synchronize accurately, whether PLC modules communicate without latency, and whether...

Modern industrial automation, autonomous robots, and collaborative robotic systems depend heavily on Robotics PCBs as the central electronic platform for control, sensing, and communication. Engineers designing Robotics PCBs face unique challenges: ensuring low-latency signal transmission, maintaining power stability for high-current actuators, integrating a diverse set of sensors, and protecting sensitive electronics from electromagnetic interference. 1....

Industrial Automation PCB engineering sits at the core of modern manufacturing, robotics, and process-control systems. In factory environments filled with electrical noise, high temperatures, continuous vibration, and mission-critical timing demands, the Industrial Automation PCB must deliver unwavering reliability, low signal distortion, and stable power delivery. As factories evolve toward smart, interconnected, high-speed architectures, the expectations...

Industrial Automation PCB engineering sits at the core of modern manufacturing, robotics, and process-control systems. In factory environments filled with electrical noise, high temperatures, continuous vibration, and mission-critical timing demands, the Industrial Automation PCB must deliver unwavering reliability, low signal distortion, and stable power delivery. As factories evolve toward smart, interconnected, high-speed architectures, the expectations...

Industrial Automation PCB: High-Reliability Engineering for Modern Automated Systems Industrial Automation PCB technology is the backbone of automated factories, motion-control systems, industrial robots, PLC modules, sensor interfaces, and high-duty power conversion equipment. Unlike consumer electronics, an Industrial Automation PCB must deliver continuous uptime, deterministic performance, and long operational life under electrical noise, mechanical stress, and...

Modern industrial robots, collaborative robots (cobots), AGVs, AMRs, and aerial autonomous platforms rely heavily on Robotics PCBs for motion control, sensor fusion, decision-making, communication, and continuous power delivery. As robots transition toward higher precision and autonomy, the electronic design inside them becomes increasingly complex.A well-engineered Robotics PCB determines performance in terms of stability, latency, environmental...

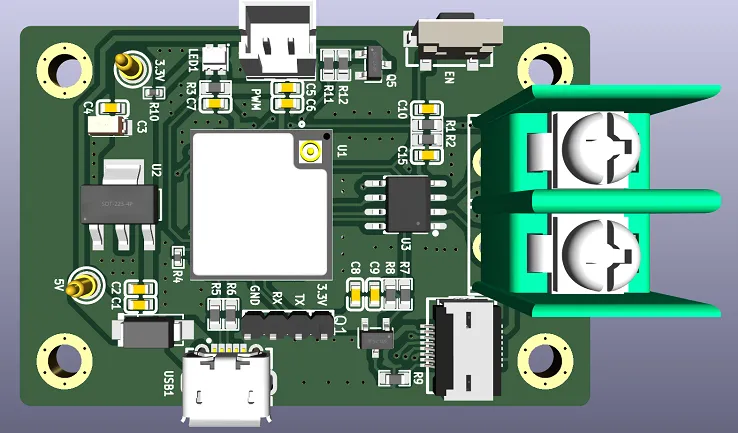

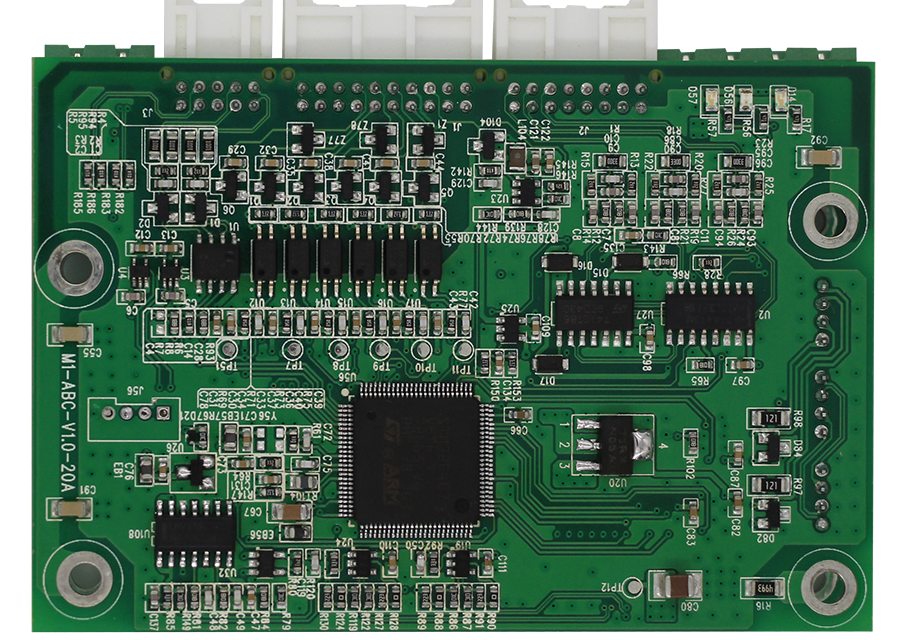

Discover how KKPCB delivered a high-reliability servo drive PCBA for a European industrial automation client. Featuring 6–8 layer HDI PCB fabrication, high-TG materials, ENIG finish, optimized thermal design, controlled impedance routing, copper-block heat management, and full SMT + DIP assembly. Achieved 45% EMI improvement, 30%+ uptime increase, <0.2% repair rate, and 12% cost reduction.