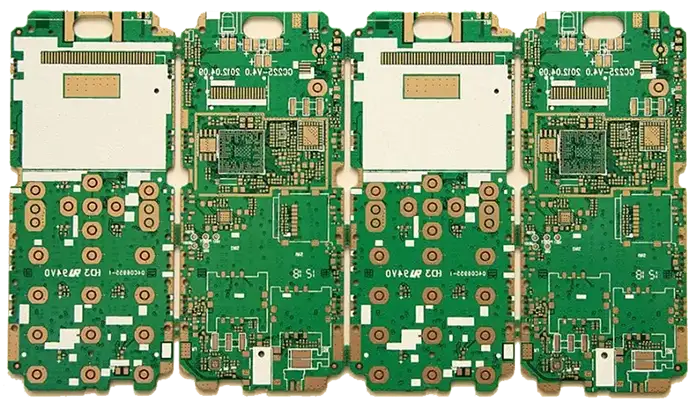

1. Engineering Overview / Abstract As 5G smartphone antenna modules integrate multiple MIMO paths and beam-forming arrays, precise impedance control and thermal uniformity become critical for stable signal transmission. Taconic RF-35 PCB substrates enable consistent dielectric performance and low-loss propagation under compact, multilayer conditions. KKPCB engineers apply fine-tuned lamination and impedance verification processes to...

HomeTag

impedance control - KKPCB

1. Engineering Overview / Abstract As precision RF test and measurement systems extend into the 40 – 110 GHz range, achieving sub-degree phase accuracy and minimal insertion-loss drift becomes a primary design requirement. Taconic RF-35 PCBs—engineered with a glass-reinforced PTFE composite (Dk = 3.50 ± 0.05, Df = 0.0018 @ 10 GHz)—enable calibration-grade impedance...

1. Engineering Overview — Material-Driven Signal Reliability for 5G Smartphones As 5G smartphones evolve toward multi-antenna, wide-band, and ultra-compact RF front-end architectures, PCB materials play a decisive role in ensuring signal alignment and thermal stability. The TLY-5 PCB, a PTFE-glass composite laminate from Taconic, provides excellent dielectric uniformity (Dk = 2.2 ± 0.02, Df...

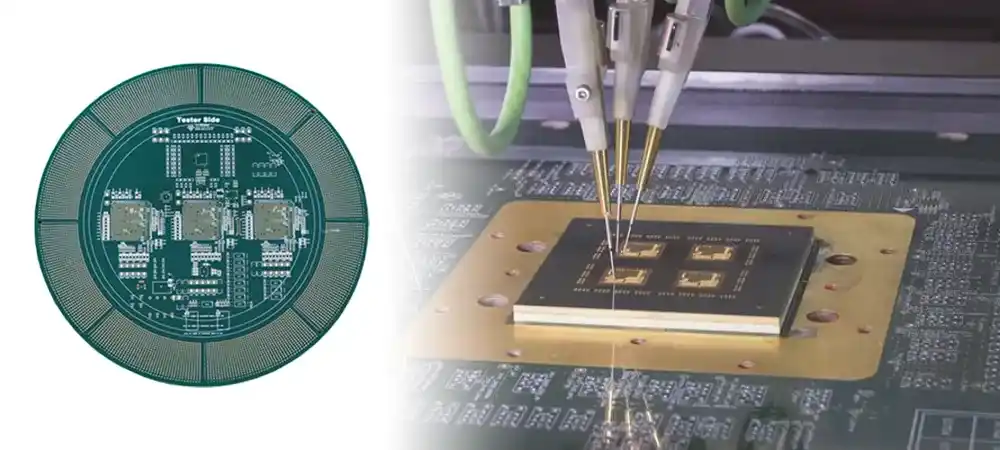

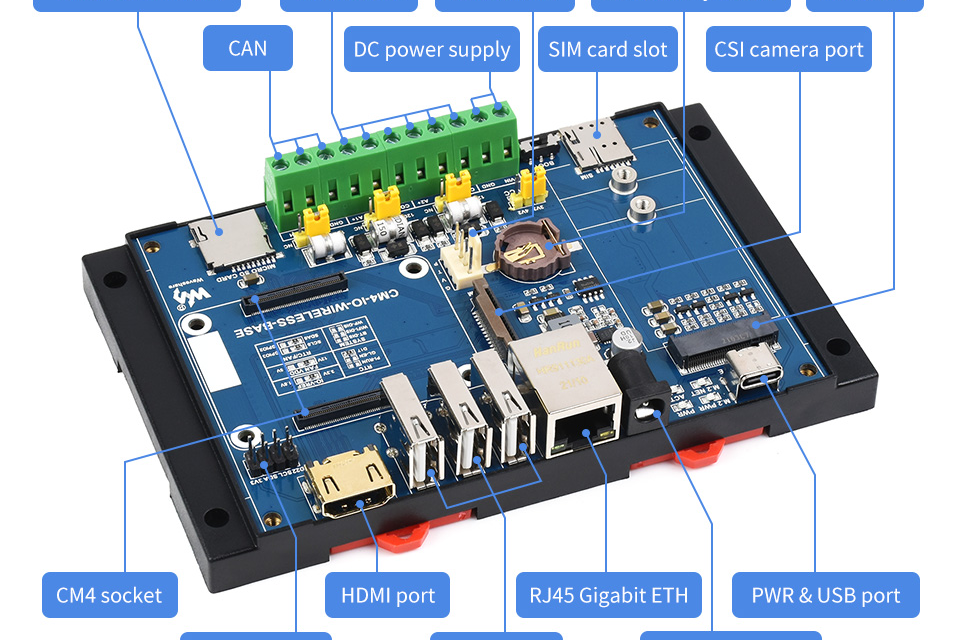

RF Test PCB: Engineering Precision for High-Frequency Testing Applications Introduction As wireless communication, semiconductor devices, and high-frequency electronics continue to advance, the demand for precise and reliable test platforms has increased dramatically. Among these platforms, the RF Test PCB plays a central role. It enables engineers to validate RF performance, measure high-frequency characteristics, and ensure...

Probe Card PCB: Engineering Precision for Wafer-Level Testing Introduction At the wafer-level test stage, the probe card PCB serves as the indispensable interface between automated test equipment (ATE) and the semiconductor wafer. As device geometries continue shrinking and electrical performance requirements become more demanding, precision test interfaces have become essential. The probe card PCB establishes...

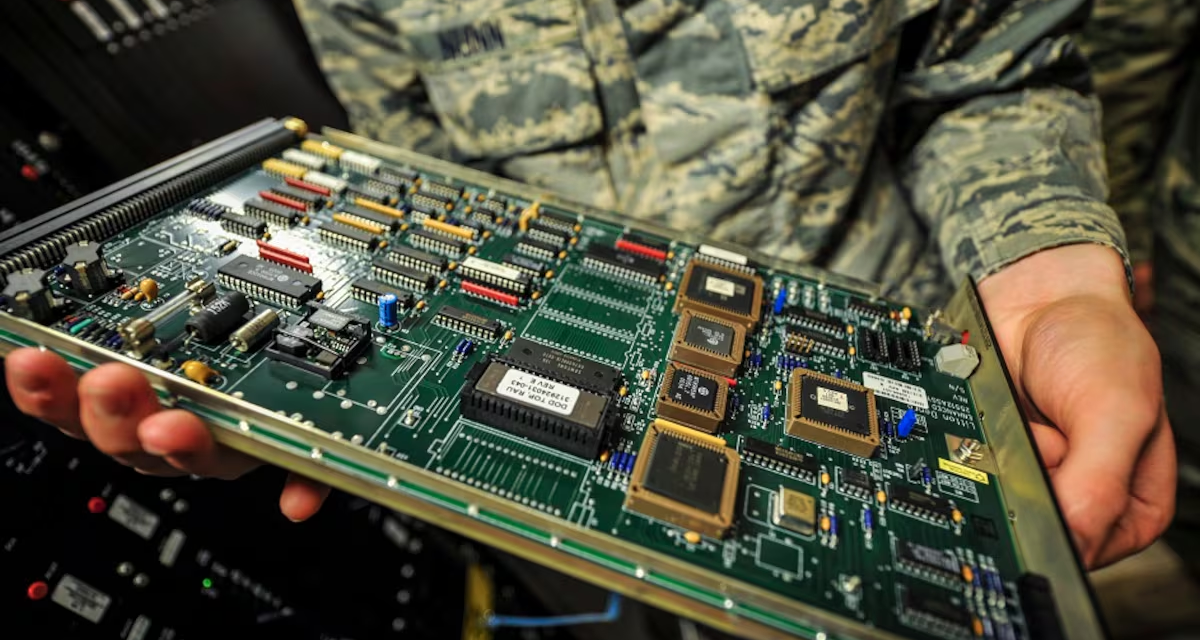

1. Introduction In advanced RF and microwave test systems, where signal accuracy defines measurement integrity, the substrate material directly determines consistency. The RF-35 PCB—a low-loss laminate with optimized dielectric uniformity—has become a preferred platform for network analyzers, calibration modules, and power sensors operating between 20 GHz to 50 GHz. KKPCB’s engineering framework addresses key...

Engineering Context — RF-35 PCB for Next-Generation Industrial mmWave Networks Industrial IoT communication is rapidly shifting toward 28 GHz to 60 GHz mmWave domains, demanding high-power amplifier (HPA) modules that deliver low-loss signal routing, stable gain, and robust thermal reliability.At these frequencies, the choice of PCB substrate directly determines the performance envelope of the...

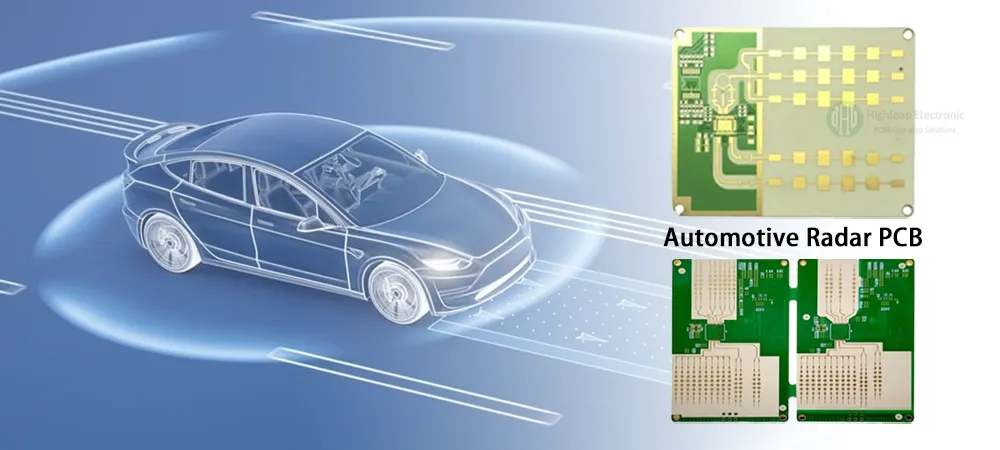

Engineering Context — Why RF-35 PCB Is Key to Automotive Radar Precision As modern automotive radar systems evolve toward 76–81 GHz mmWave operation, PCB materials must ensure phase stability, low insertion loss, and precise impedance control across multiple layers.The RF-35 PCB, a Taconic PTFE glass-reinforced laminate, combines Df = 0.0018 @ 10 GHz and...

The Challenge — Miniaturization vs. RF Integrity In the race toward smaller, lighter, and more integrated microwave systems, engineers face an unavoidable trade-off: how to pack more functionality—LNAs, filters, phase shifters, power amplifiers—into limited PCB real estate without compromising signal integrity or dielectric stability. Rogers Duroid 6010, with its high dielectric constant (Dk...

Signal Integrity and Cavity Resonance Control in Duroid 6010 PCB Substrates for RF Front-End Modules

Why Cavity Resonance Is the Hidden Enemy in High-Dk RF Boards In high-frequency RF front-end modules—especially those operating beyond 20 GHz—engineers often encounter unexpected resonance spikes, gain ripple, and phase drift despite ideal simulations. The culprit is frequently cavity resonance—localized standing waves caused by dielectric thickness, copper enclosure geometry, or high-Dk material behavior. ...