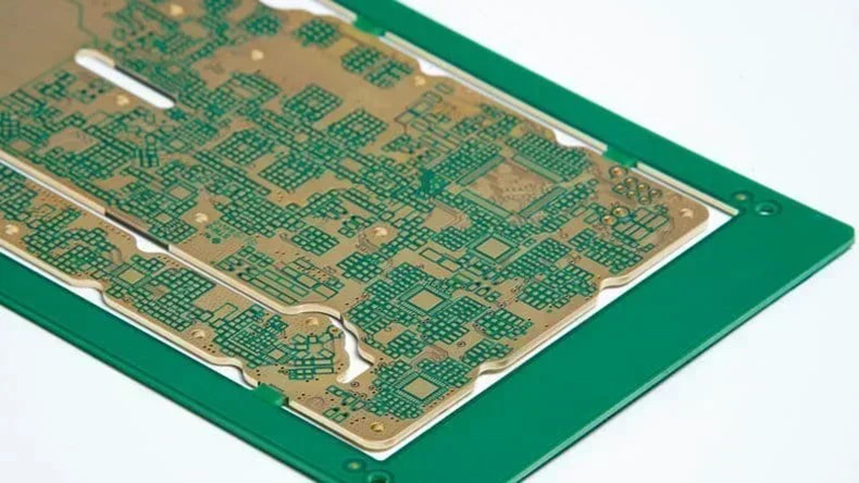

High TG materials are specialized PCB laminates and prepregs engineered to operate reliably under elevated temperatures, repeated thermal cycling, and high-density multilayer stackups. TG, or glass transition temperature, defines the point at which the resin matrix softens, directly affecting mechanical stability, dimensional integrity, and electrical performance. In advanced electronic systems, selecting high TG materials is...

HomeTag

High Temperature PCB - KKPCB

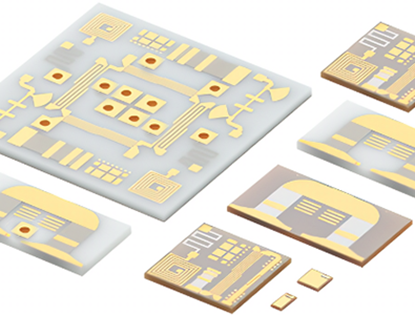

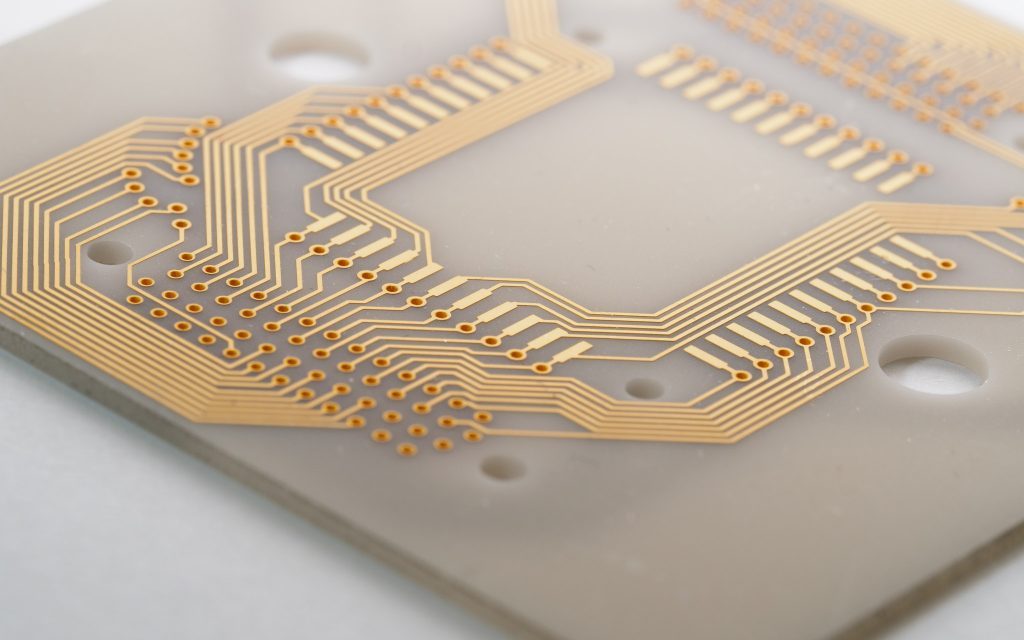

Aluminum Nitride PCB (AlN PCB) is a ceramic substrate technology specifically engineered for electronic systems where power density, thermal stress, and operating temperature exceed the limits of conventional PCB materials. In high-power and high-temperature environments, Aluminum Nitride PCBs serve not only as circuit carriers but as primary thermal management and reliability enablers. Why Aluminum Nitride...

High Tg Materials: A Critical Upgrade for Reliable PCB Performance Modern electronic products are operating under increasingly demanding conditions—higher power density, higher assembly temperatures, and more complex multilayer designs. As a result, PCB materials must deliver stronger thermal stability and long-term reliability. This is why High Tg materials have become a common choice in automotive,...

Aluminum Nitride PCB: The Premium Ceramic Substrate for Advanced Thermal Management As modern electronics continue to push toward higher power density, smaller size, and higher reliability, thermal management becomes a key design challenge. In applications such as power modules, EV systems, high-brightness LEDs, and industrial converters, standard PCB materials often struggle to dissipate heat effectively....

Ceramic PCB: The Ideal Solution for Heat Dissipation and High-Reliability Electronics As electronic products become smaller, more powerful, and more integrated, thermal management has become one of the biggest challenges in modern PCB design. In applications such as power modules, high-brightness LEDs, automotive electronics, and industrial control systems, standard FR4 boards may struggle with heat...

As modern electronics continue to evolve toward higher power density, smaller packaging, and harsher operating environments, thermal performance has become one of the most important factors in PCB material selection. In applications such as EV power modules, IGBT and MOSFET power stages, SiC/GaN devices, and high brightness LED modules, traditional FR-4 PCBs often cannot provide...

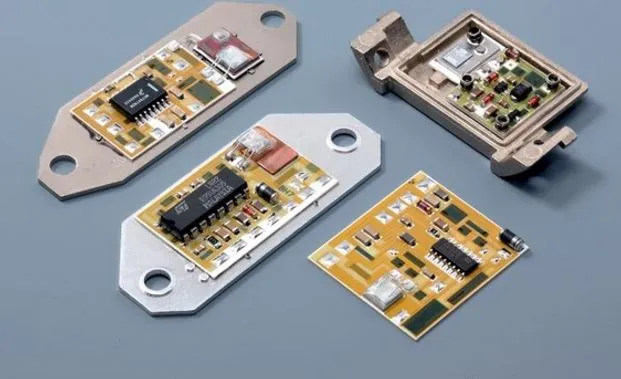

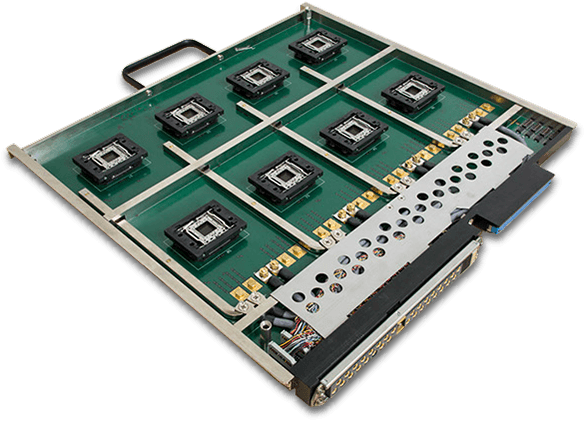

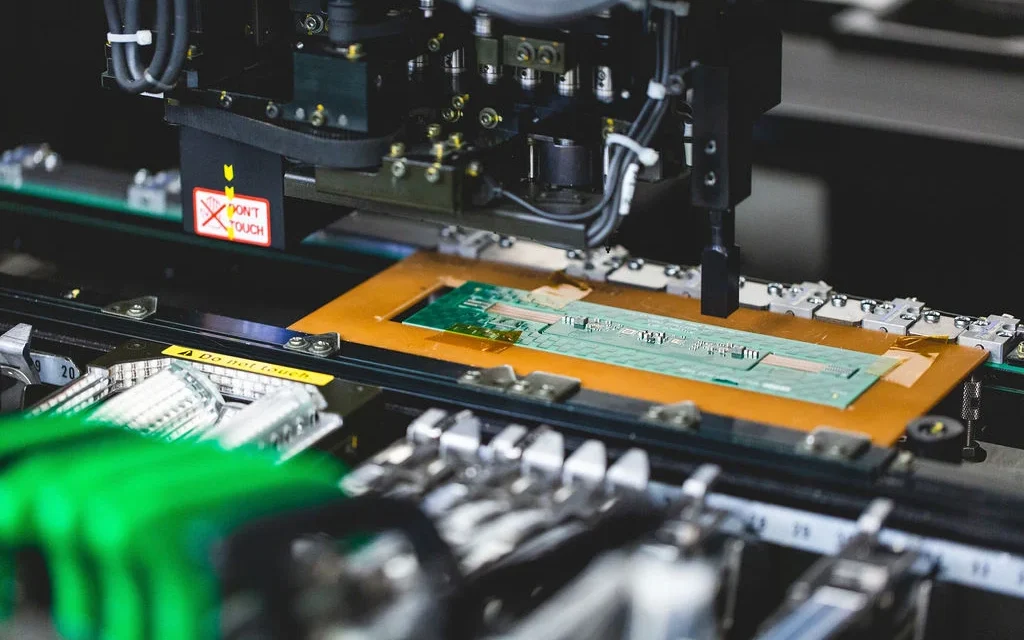

A Burn-in Board PCB is a specialized semiconductor test PCB used during the burn-in process, where integrated circuits are operated under elevated temperature, voltage, and extended time conditions to detect early-life failures. This testing stage is critical for improving IC reliability before devices enter mass production or high-reliability applications. Burn-in boards serve as the electrical...

A Burn-in Board PCB is a specialized semiconductor test PCB used during the burn-in process to identify early-life failures in integrated circuits. Installed in burn-in ovens or Automated Test Equipment (ATE) systems, burn-in board PCBs operate under elevated temperatures, extended test durations, and high electrical stress, making reliability and material stability critical. Unlike standard IC...

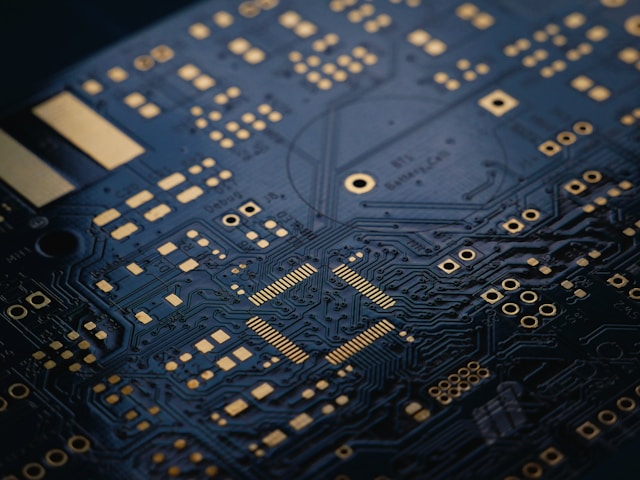

Engineering Context: Why High TG PCB Is Critical in Modern Electronics As electronic systems continue to push toward higher power density, faster signal speeds, and harsher operating environments, conventional PCB materials increasingly become a reliability bottleneck. Excessive heat, repeated thermal cycling, and dense component placement place enormous stress on standard laminates, often leading to warpage,...

High TG PCB technology has become a cornerstone for high-temperature, high-power, and long-duty-cycle electronic systems. As devices shrink, current density rises, and thermal loads increase, traditional FR-4 can no longer maintain stability. This is where High TG PCB materials—TG170, TG180, and beyond—deliver the thermal robustness and dimensional stability required for demanding environments. High TG (Glass...