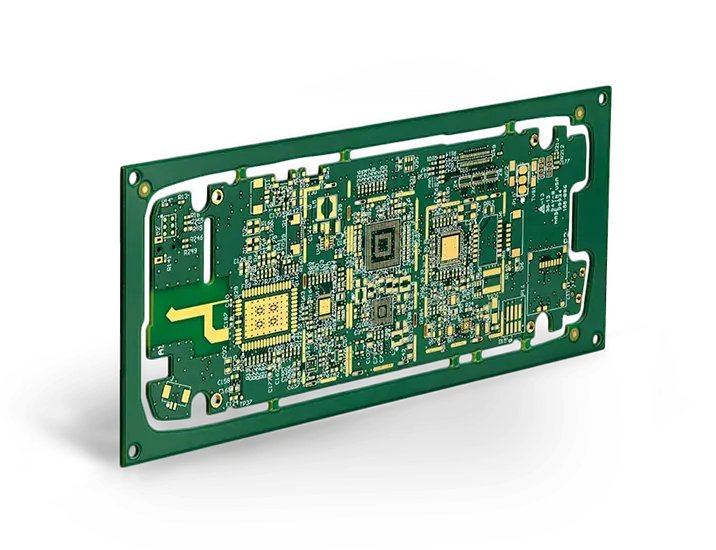

What Is an Impedance Controlled PCB? An Impedance Controlled PCB is a printed circuit board designed with precisely engineered impedance values for high-speed or high-frequency signal paths. These PCBs ensure signal integrity, minimal reflection, and low insertion loss, which are critical for RF modules, 5G routers, high-speed digital circuits, automotive electronics, and sensor interfaces. Key...

HomeTag

high-frequency PCB - KKPCB

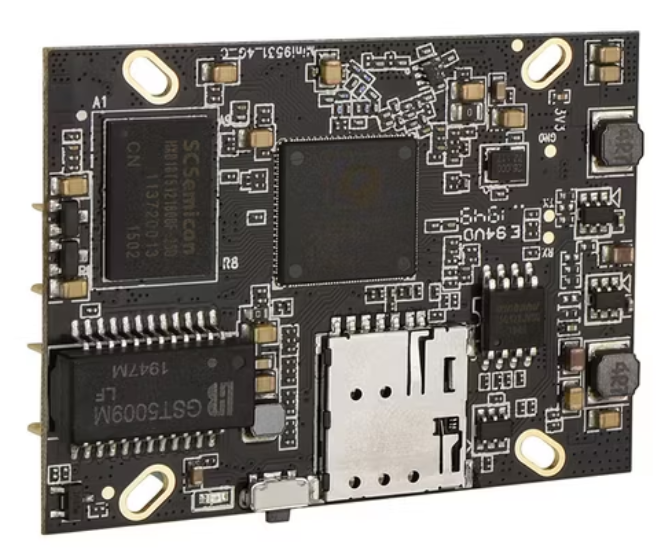

What Is a 5G Router PCB? A 5G Router PCB is a printed circuit board specifically developed for 5G wireless routers and communication devices, supporting high-speed signal transmission, low-loss RF paths, and stable impedance. These PCBs are essential for 5G base stations, routers, gateways, and mmWave communication modules, ensuring fast and reliable network performance. Key...

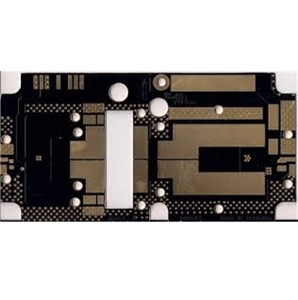

What Is a Megtron 7 PCB? A Megtron 7 PCB is a high-performance printed circuit board manufactured using Panasonic Megtron 7 laminate, designed for ultra-high-speed digital and high-frequency signal transmission. It is widely used in applications that demand exceptional signal integrity, extremely low transmission loss, and stable electrical performance. Megtron 7 PCB is commonly selected...

What Is an RF-35 PCB? An RF-35 PCB is a high-frequency printed circuit board fabricated with Taconic RF-35 laminate, designed for RF and microwave applications that require low loss, stable dielectric constant, and reliable impedance control. RF-35 PCB material provides excellent electrical performance while maintaining good manufacturability, making it suitable for both prototype and production...

What Is an RO4835 PCB? An RO4835 PCB is a high-frequency printed circuit board fabricated with Rogers RO4835 laminate, designed for RF and microwave applications requiring low loss, stable dielectric properties, and consistent impedance control. Rogers RO4835 material combines the electrical performance of PTFE-based laminates with the manufacturability of standard FR-4 processes, making it ideal...

What Is a Low Loss PCB? A Low Loss PCB is a printed circuit board engineered to reduce signal attenuation, insertion loss, and distortion during high-speed or high-frequency signal transmission. Low loss PCBs are essential in applications such as 5G communication, mmWave modules, data centers, automotive radar, and AI servers, where signal integrity is critical....

What Is a mmWave Module PCB? A mmWave Module PCB is a specialized printed circuit board used in millimeter-wave (mmWave) modules, typically operating at frequencies above 24 GHz, such as 26 GHz, 28 GHz, 39 GHz, and 77 GHz. These PCBs integrate RF transceivers, antennas, filters, and high-speed interfaces into compact modules. Due to the...

What Is a 5G Router PCB? A 5G router PCB is a printed circuit board specifically designed for 5G wireless routers and gateways, supporting high-frequency RF signals, high-speed digital processing, and stable power delivery. These PCBs integrate RF front-end circuits, baseband processing, power management, and high-speed interfaces on multilayer boards. Compared with traditional 4G router...

What Is Megtron 7 PCB? A Megtron 7 PCB is a high-performance printed circuit board fabricated using Panasonic Megtron 7 laminate, an ultra-low loss material developed for high-speed digital and high-frequency signal transmission. Megtron 7 PCBs are widely used in data centers, AI servers, networking equipment, and advanced computing systems where signal integrity is critical....

What Is RF-35 PCB? An RF-35 PCB is a high-frequency printed circuit board fabricated using Taconic RF-35 laminate, a woven glass–reinforced hydrocarbon ceramic material designed for RF and microwave circuits. RF-35 PCB offers low dielectric loss, stable dielectric constant, and excellent dimensional stability, making it a reliable choice for high-frequency electronic designs. Compared with standard...