What Are High TG Materials? High TG materials refer to PCB laminate materials with a high glass transition temperature (Tg), typically above 170°C and often reaching 180°C–200°C or higher. The Tg value indicates the temperature at which the PCB material transitions from a rigid glass-like state to a softer rubber-like state. Using high TG materials...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

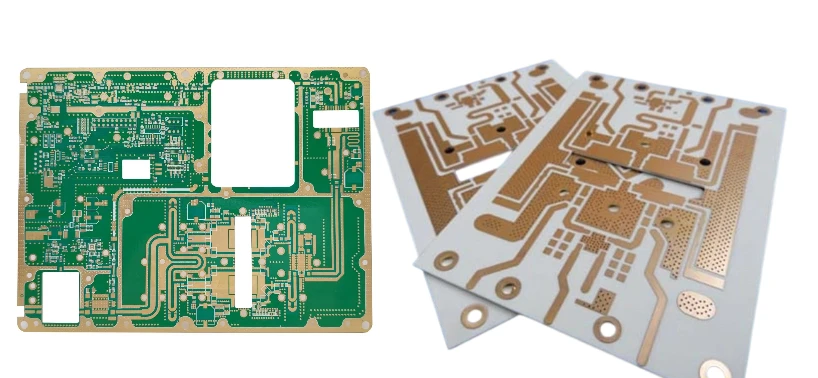

What Are Low Loss Materials? Low loss materials are specialized PCB laminate materials designed to minimize signal attenuation in high-speed and high-frequency circuits. Compared to standard FR-4 materials, low loss materials provide: Lower dissipation factor (Low Df) Stable dielectric constant (Dk) Reduced insertion loss Improved signal integrity Better high-frequency performance Low loss materials are essential...

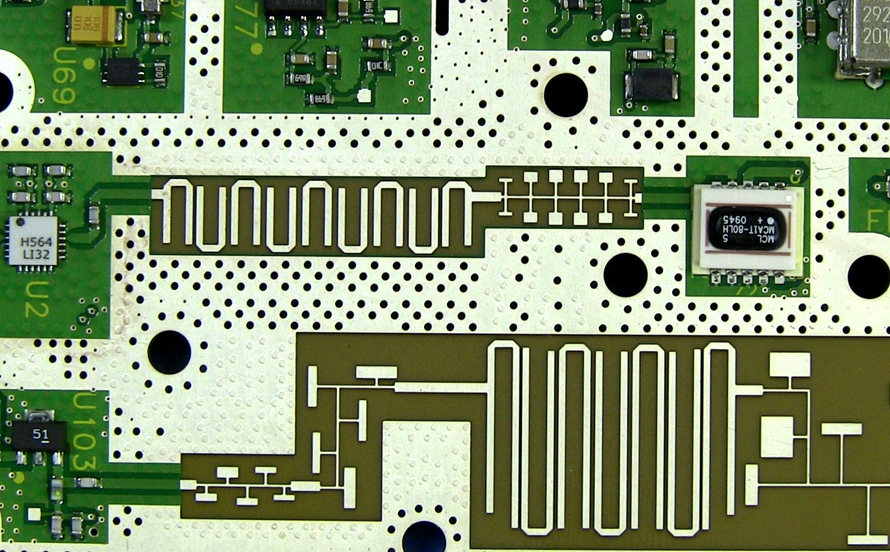

What Are High Frequency Laminates? High Frequency Laminates are specialized PCB base materials engineered for high-speed and high-frequency electronic applications. Unlike standard FR-4 materials, high frequency laminates offer: Low dielectric constant (Low Dk) Low dissipation factor (Low Df) Stable electrical performance at GHz frequencies Excellent signal integrity Reliable controlled impedance performance High frequency laminates are...

What Is a BT Epoxy PCB? A BT Epoxy PCB is a high-performance printed circuit board manufactured using Bismaleimide Triazine (BT) resin-based epoxy material. BT Epoxy PCB is widely used in IC substrate applications, semiconductor packaging, memory modules, and high-density electronic devices, where thermal stability, dimensional accuracy, and electrical performance are critical. Compared with standard...

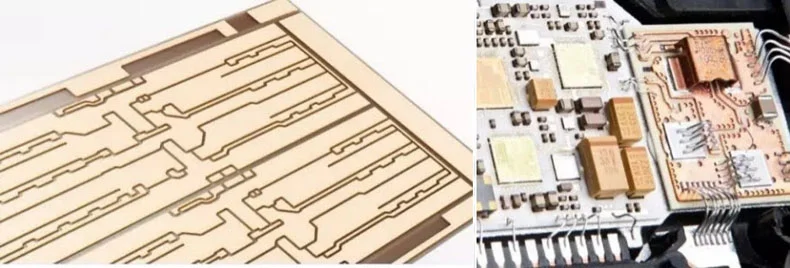

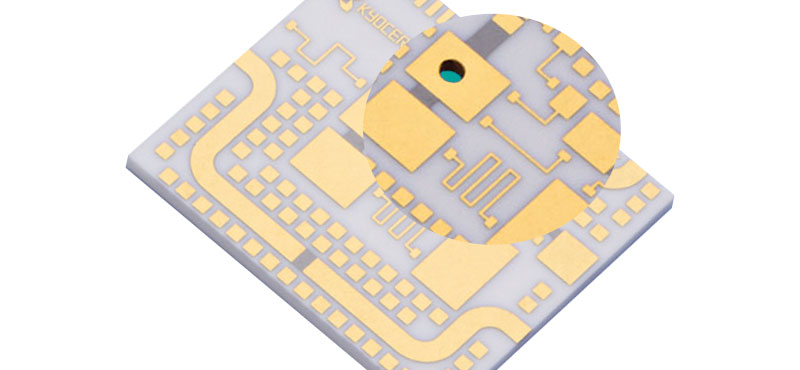

What Is an Aluminum Nitride PCB? An Aluminum Nitride PCB (AlN PCB) is a high-performance ceramic printed circuit board manufactured using Aluminum Nitride substrate material, known for its exceptionally high thermal conductivity and excellent electrical insulation properties. Compared to traditional FR-4 or even Alumina ceramic PCBs, Aluminum Nitride PCB offers significantly enhanced heat dissipation performance,...

What Is a Ceramic PCB? A Ceramic PCB is a high-performance printed circuit board manufactured using ceramic substrate materials such as Alumina (Al₂O₃), Aluminum Nitride (AlN), or Beryllium Oxide (BeO). Unlike traditional FR-4 PCBs, Ceramic PCBs provide: Excellent thermal conductivity High mechanical strength Superior electrical insulation Stable performance in extreme environments Ceramic PCB technology is...

What Is an RO4003C PCB? An RO4003C PCB is a high-frequency printed circuit board manufactured using Rogers RO4003C laminate, a hydrocarbon ceramic-filled material specifically engineered for low loss RF and microwave applications. RO4003C PCBs are widely used in: RF and microwave circuits 5G base station modules Automotive radar systems Satellite communication equipment High-speed digital and...

What Is a PTFE PCB? A PTFE PCB is a printed circuit board made from polytetrafluoroethylene (PTFE) laminates, known for extremely low dielectric loss, stable dielectric constant, and excellent high-frequency performance. PTFE PCBs are widely used in 5G, mmWave modules, RF/microwave systems, aerospace electronics, and high-speed computing, where signal integrity and low insertion loss are...

What Is a Rogers PCB? A Rogers PCB is a printed circuit board that uses Rogers high-frequency laminates, such as RO4003C, RO4350B, and Duroid series, designed for low dielectric loss, precise impedance control, and high-frequency signal transmission. Rogers PCBs are essential in 5G communications, RF/microwave modules, high-speed computing, and aerospace electronics. Why Rogers PCB Technology...

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to carry high-speed and high-frequency signals with minimal loss, reflection, or distortion. These PCBs are crucial in RF, microwave, 5G, high-speed computing, and semiconductor test applications, where signal integrity and low insertion loss are essential for system...