As 5G RF front-end modules push into sub-6 GHz and mmWave bands, PCB materials must deliver extreme electrical precision, low-loss propagation, and predictable thermal behavior. TLY-5 PCB laminates, based on PTFE composites engineered with ultra-low dielectric constant (Dk ≈ 2.17) and low dissipation factor (Df ≈ 0.0009), have emerged as one of the most reliable...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

Precision mmWave routing networks—operating from 26 GHz to beyond 90 GHz—demand exceptional electromagnetic uniformity, controlled impedance, and stable mode behavior to maintain system linearity. RT/duroid 5880 PCB materials have become a foundational high-frequency laminate for mmWave architectures because their ultra-low dielectric constant (Dk ≈ 2.20), extremely low dissipation factor (Df ≈ 0.0009), and isotropic PTFE...

High-Q RF filters operating in microwave, mmWave, radar, and satellite communication systems demand exceptionally stable phase behavior and predictable wideband propagation. Rogers 5880 PCB laminates have become a preferred high-frequency substrate because their ultra-low dielectric constant (Dk 2.20) and extremely low dissipation factor (Df 0.0009) enable ultra-flat phase response, low-loss signal transmission, and coherent filter...

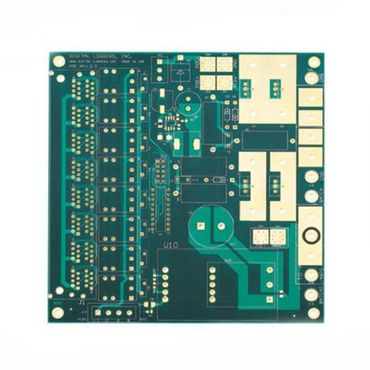

Introduction: Why PCB Prototype Engineering Defines Modern Electronics A PCB Prototype is no longer just a pre-production sample—it is the central engineering stage that determines product performance, manufacturability, reliability, and cost.In advanced electronics such as 5G, IoT, robotics, automotive, aerospace, AI edge computing, and industrial automation, a well-engineered PCB Prototype ensures signal integrity, thermal stability,...

Modern industrial robots, collaborative robots (cobots), AGVs, AMRs, and aerial autonomous platforms rely heavily on Robotics PCBs for motion control, sensor fusion, decision-making, communication, and continuous power delivery. As robots transition toward higher precision and autonomy, the electronic design inside them becomes increasingly complex.A well-engineered Robotics PCB determines performance in terms of stability, latency, environmental...

TLY-5 PCB materials have become a core enabler in modern high-frequency electronics, especially as RF, microwave, and mmWave systems continue pushing toward higher bandwidth, lower loss, and stricter phase-stability requirements. Built on a PTFE-based low-loss dielectric platform, TLY-5 PCBs deliver exceptionally high electrical performance while supporting the reliability demands of satellite payloads, radar front-ends, high-power...

Mission-critical aerospace and high-frequency communication systems depend on PCB materials that deliver absolute electrical stability, consistent power efficiency and repeatable RF performance under extreme thermal, mechanical and radiation environments. RO5880 PCB architectures have become a foundation for these systems because they offer exceptionally stable Dk/Df, low insertion loss and predictable phase behavior across microwave and...

PCB Assembly (PCBA)Electronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Reduce Conductor Loss and Maintain High-Frequency Linearity with Duroid 5880 PCB Microstrip/Coplanar Structures for Advanced Microwave Modules

Advanced microwave modules demand transmission structures that deliver extremely low loss, high linearity and wideband frequency stability. Modern radar front-ends, satellite communication units and mmWave transceivers rely heavily on Duroid 5880 PCB technology because it offers exceptionally low dielectric loss, high-frequency predictability and precise impedance behavior. When engineered into microstrip and coplanar waveguide (CPW) structures,...

Modern electronics development depends on fast, accurate, and predictable PCB prototype fabrication. As device complexity rises—spanning RF modules, 5G transceivers, AI accelerators, and densely integrated consumer electronics—engineering teams rely on high-precision prototyping to validate architectures before mass production. PCB prototype technology has evolved from simple single-layer boards into a highly automated, material-specific, impedance-controlled manufacturing discipline....

1. Engineering Context Next-generation mmWave communication systems—including 5G base stations, satellite payloads, and radar modules—require PCBs that provide ultra-stable impedance, low insertion loss, and phase-consistent routing. Traditional FR-4 or high-speed laminates often suffer from dielectric drift, higher Df, and thermal expansion issues, which degrade signal fidelity, EMI immunity, and system reliability in dense multi-layer RF...