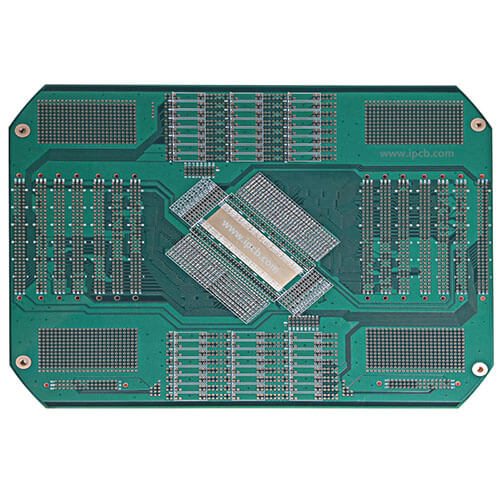

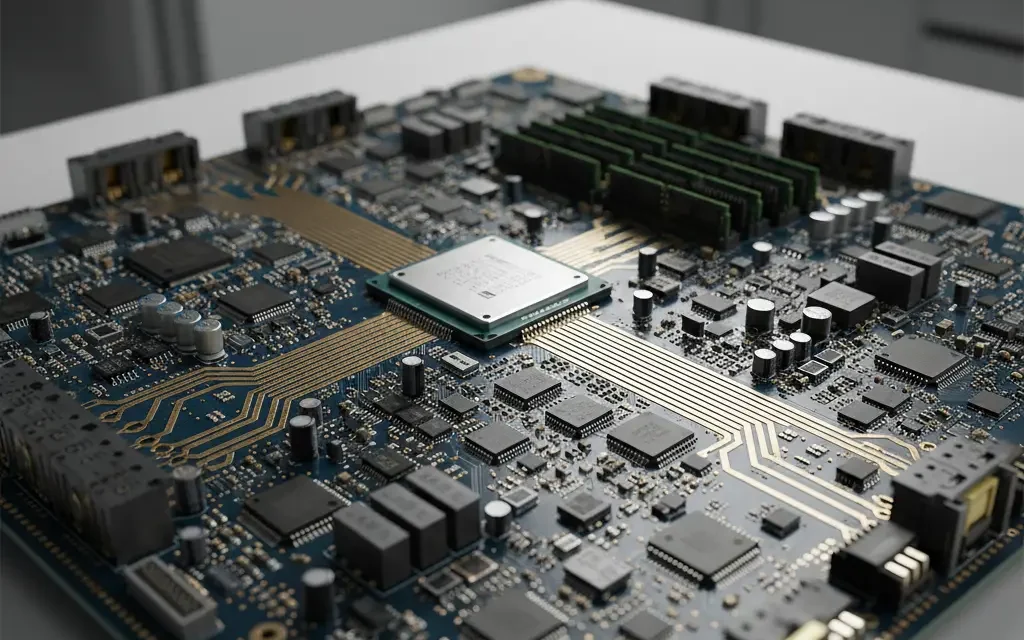

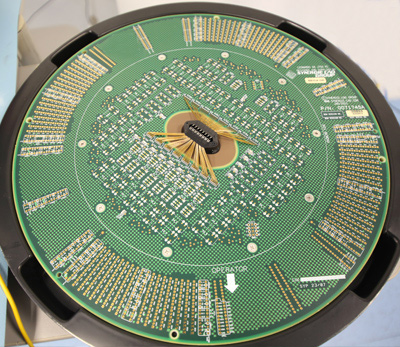

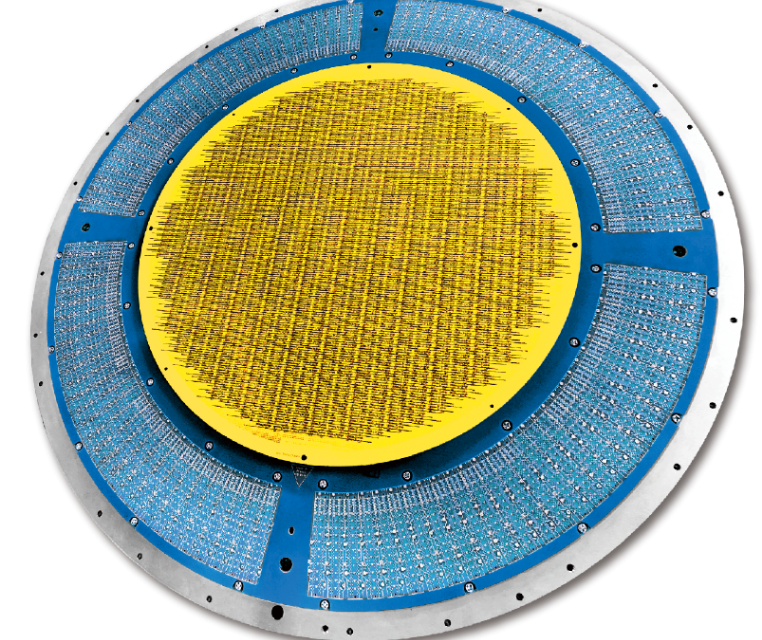

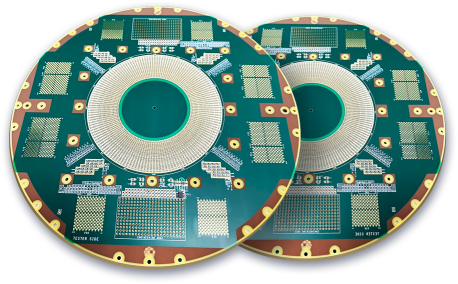

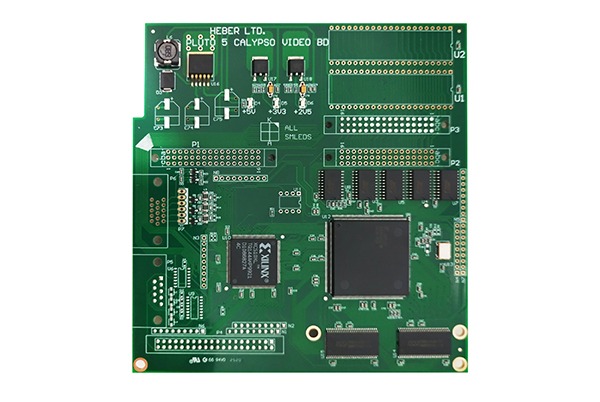

Small Batch ATE PCB Manufacturing for Semiconductor and Automated Test Equipment

Small Batch ATE PCB manufacturing is designed to support semiconductor and automated test equipment (ATE) applications that require low-volume production with high performance and reliability. Unlike mass production PCBs, small batch ATE PCBs are typically used for engineering validation, system qualification, pilot runs, and customized test solutions. As test requirements continue to evolve rapidly, small...