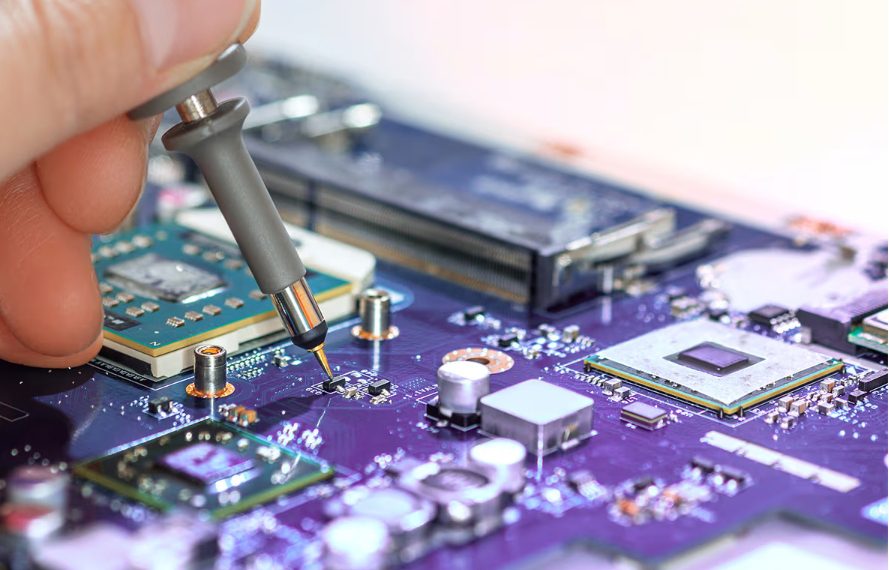

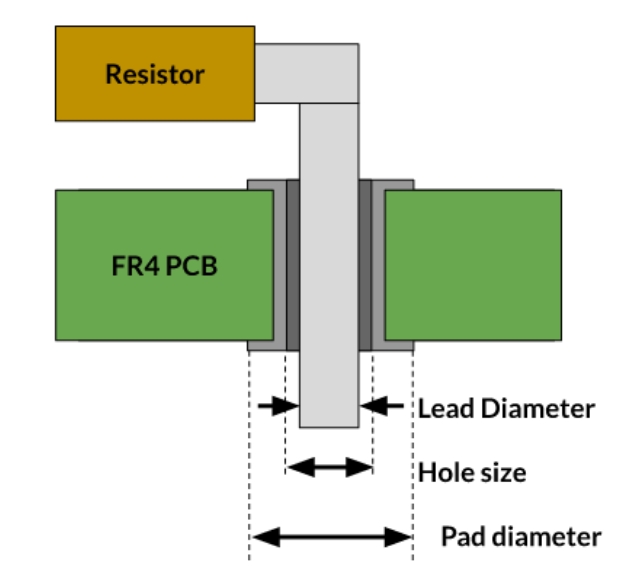

At the heart of nearly every electronic product today is a printed circuit board (PCB), which supports and electrically connects the electronic components needed for an electronic device to function. Manufacturing a printed circuit board is a complex process that involves many steps that are different for every project. First, you need to design the board...

HomeCategory

PCB Assembly (PCBA) Services | Turnkey Solutions - KKPCB

Customer Background: Our customer is a leading communication equipment company specializing in the development and manufacturing of high-frequency devices for 5G communication systems. Due to the high-frequency signal transmission requirements of their products, their PCB design demands extremely high signal integrity and strong anti-interference capabilities. Product Complexity: The primary challenge of this project was ensuring that the high-frequency...

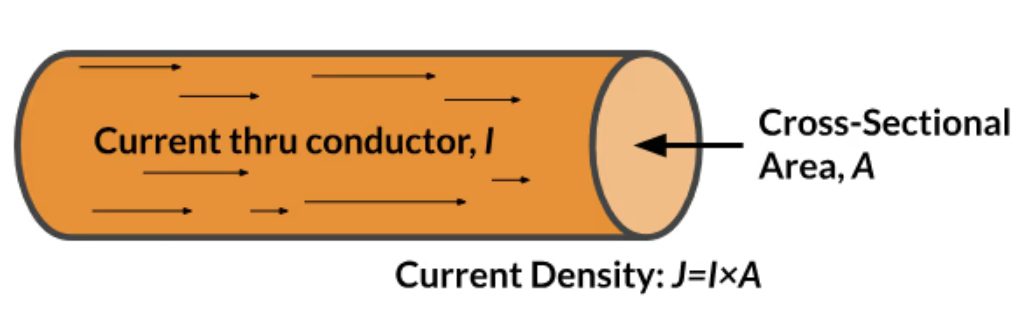

Copper current density refers to the amount of continuous current going through a copper wire —whether on a circuit board as a trace or not. According to the principles of Joule or Ohmic heating (represented as VI or I²R), any material that conducts electricity will generate heat, leading to a gradual rise in temperature in...

Low power circuit design includes strategies focused on minimizing both dynamic and static power usage in your printed circuit boards. While selecting components with low power requirements is a crucial element, low power PCB design involves more comprehensive considerations to effectively manage power consumption. Lower Power Circuit Designs Tips Aspect Description Identify Major Power Consumers Start by...

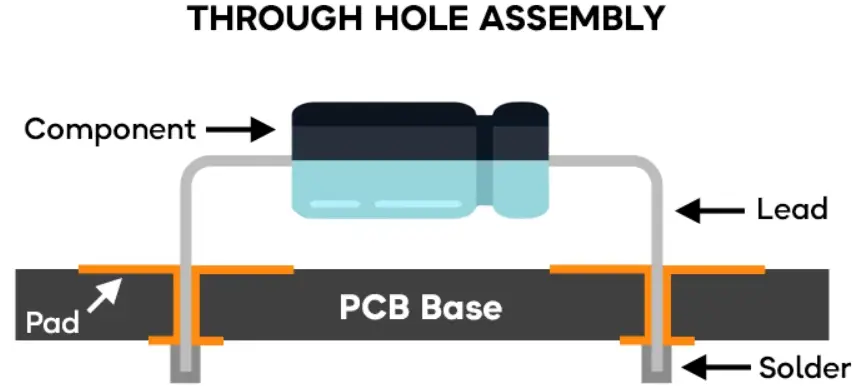

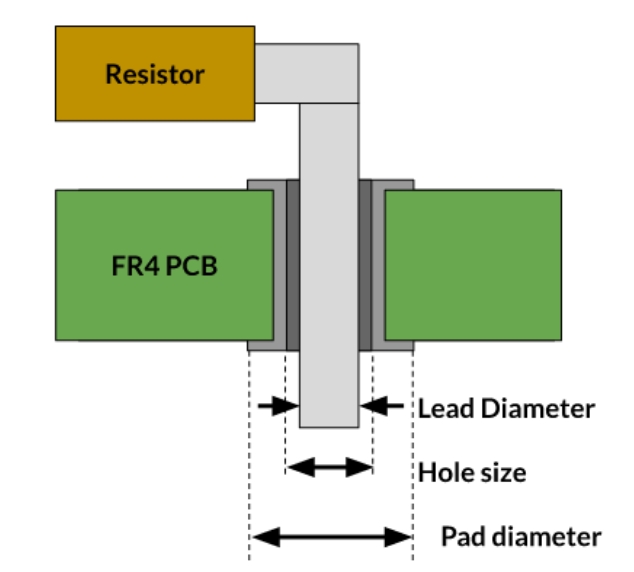

In printed circuit board (PCB) design, the choice of pad type plays a critical role in determining the durability, reliability, and performance of the final product. Through-hole pads, which are designed for components with leads that pass through the PCB, offer superior mechanical and electrical connections compared to surface mount pads. This article explores the design steps for...

In printed circuit board (PCB) design, copper pads are points for attaching components with soldering. These pads come in two primary types: through-hole and surface-mount (SMD). Through-hole pads are designed for components with leads that are inserted through the pad’s holes and soldered on the opposite side of the board. This method ensures a mechanical and electrical bond between...

1. Customer Background The customer is a globally leading manufacturer of communication equipment, specializing in the development and production of large-scale routers, switches, servers, and high-speed networking devices. As modern network communications demand increasingly high signal integrity, reliability, and thermal stability, the customer required an 36-layer PCB with low-loss material (S1000-2M) and advanced immersion gold plating to ensure stable signal transmission...

Project Background A manufacturing plant in California sought to reduce electricity costs through a distributed rooftop solar system while enhancing its green and sustainable corporate image. With ample rooftop space available, the company required a highly efficient MPPT solar controller capable of maximizing solar energy utilization and ensuring stable operation. ⚡The Role of PCBA Technology...

KKPCB provides precision PCBA manufacturing and assembly solutions for extreme environments in sewage treatment plants across Europe, America, and the Middle East. Our PCBA solutions ensure high reliability, dust and corrosion resistance, long-term stability, and intelligent control for PLC-based automation systems. Optimized for high temperature, high humidity, and corrosive conditions, our boards support multi-layer HDI designs and advanced Ethernet communication.

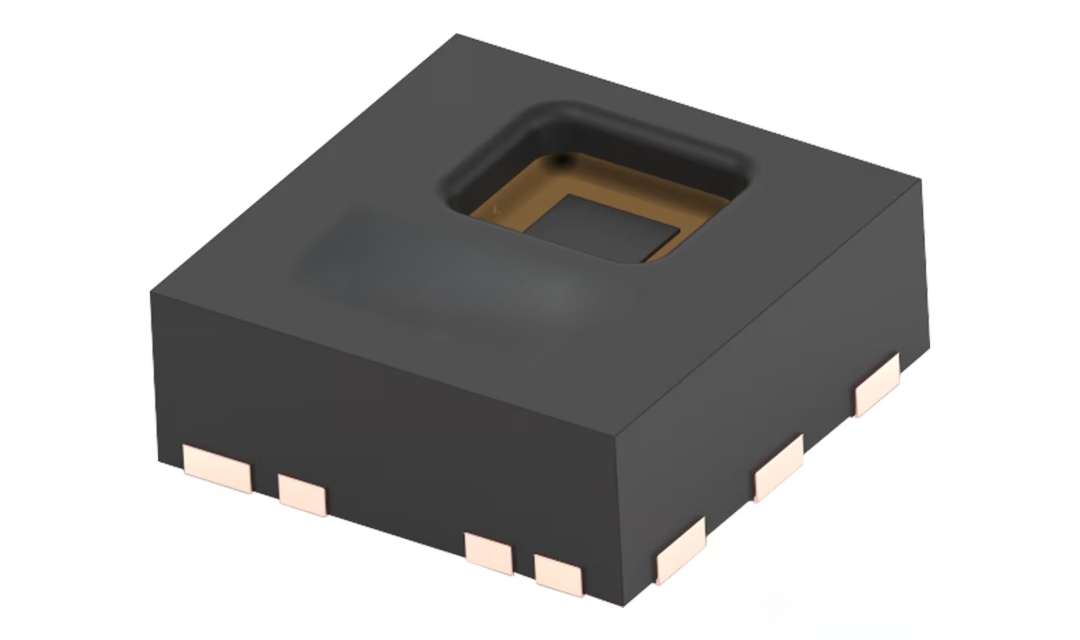

1. Background Overview A European client in the industrial automation sector required a compact, highly accurate humidity and temperature sensor solution with stable performance under harsh environmental conditions. To meet this demand, KKPCB was entrusted with providing a reliable, cost-efficient, and fast-delivery PCBA manufacturing solution for this sensor project. 2. Application Scenario The humidity and...