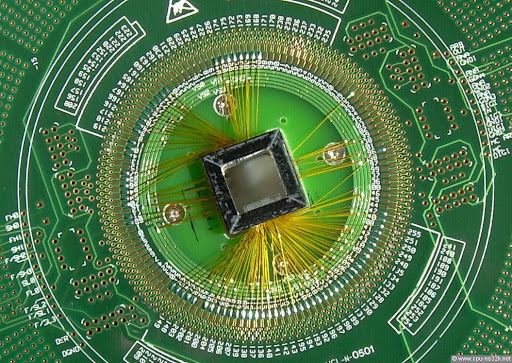

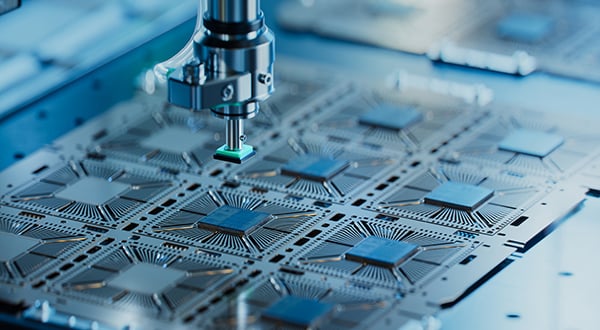

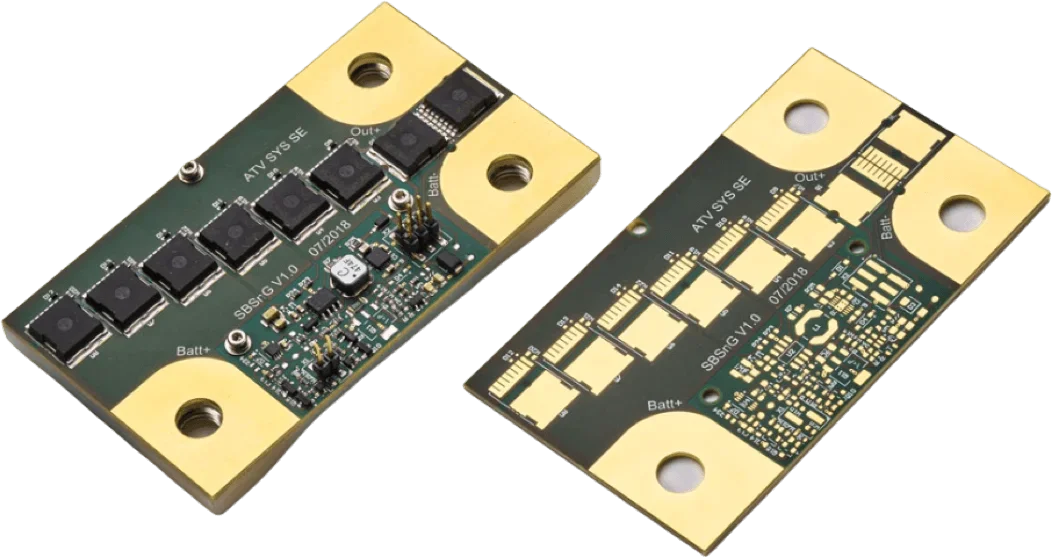

Wafer Test PCB for High-Precision Semiconductor and ATE Applications

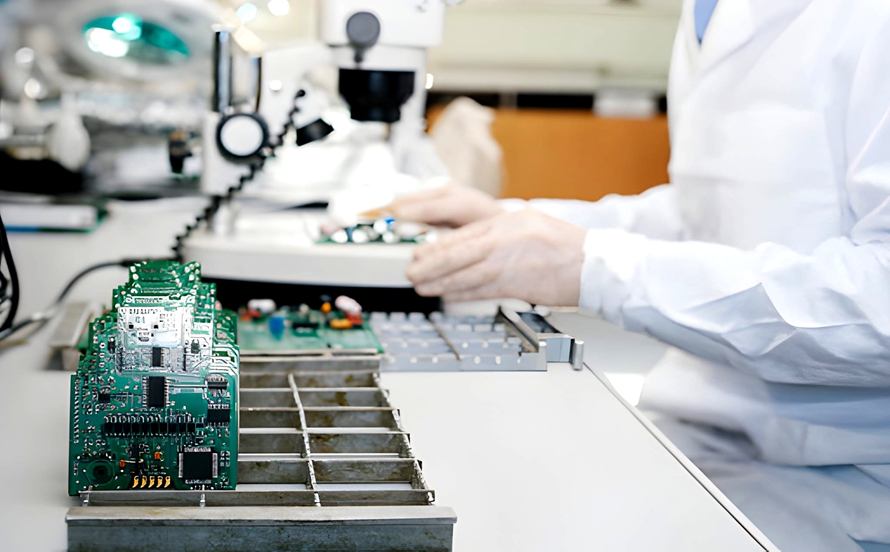

In modern semiconductor manufacturing, wafer-level testing is a critical step to ensure IC functionality, yield, and quality before packaging. Wafer Test PCBs serve as the electrical interface between probe cards and automated test equipment (ATE), enabling accurate signal transmission, high-density connections, and controlled impedance for reliable testing of wafers. By using high-quality wafer test PCBs,...