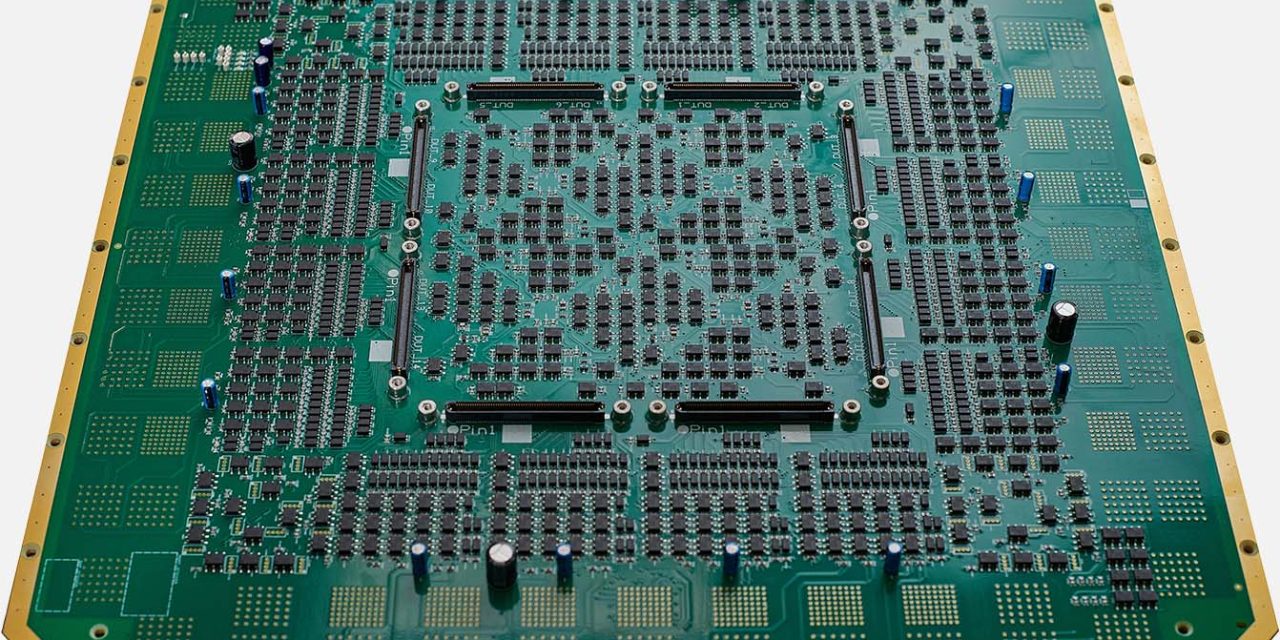

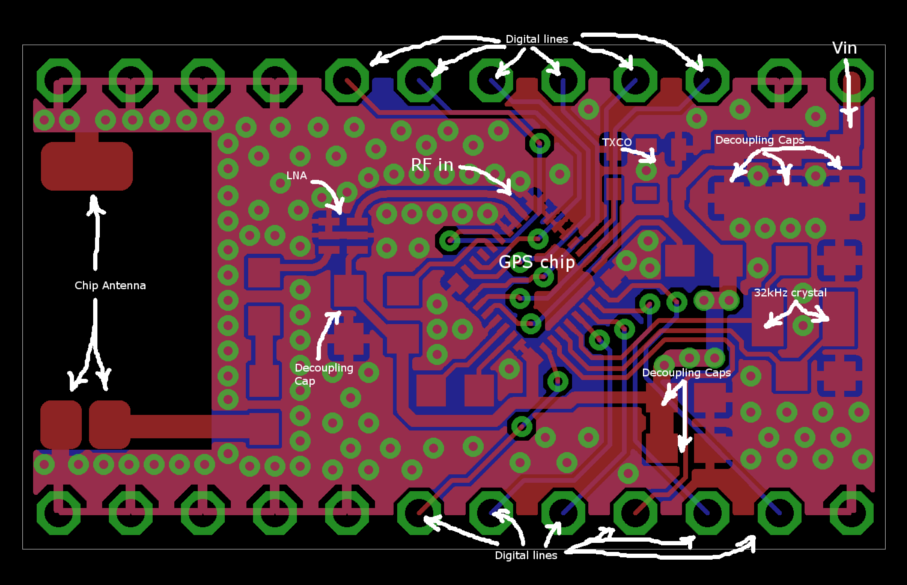

What Is a Semiconductor Load Board? A Semiconductor Load Board is a critical interface PCB used in IC testing systems, connecting the automated test equipment (ATE) to the device under test (DUT). It provides electrical routing, signal conditioning, power delivery, and mechanical support during functional, parametric, and performance testing of semiconductor devices. Load boards are...

HomeCategory

Advanced Engineering Technologies for PCB & PCBA Solutions - KKPCB

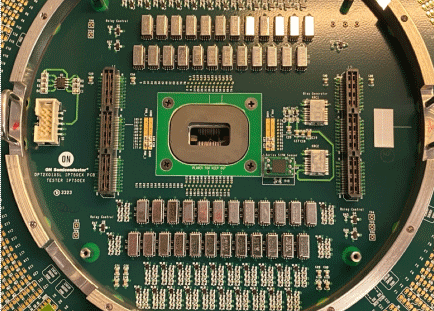

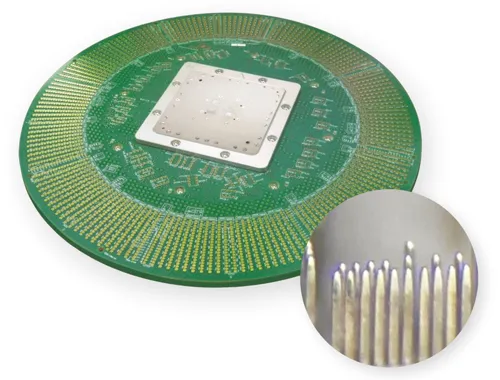

A Probe Card Assembly PCB is a highly specialized printed circuit board used in semiconductor wafer testing, acting as the critical electrical interface between the automated test equipment (ATE) and the device under test (DUT). It enables precise signal transmission from the tester to microscopic probe needles or MEMS probes that contact IC pads on...

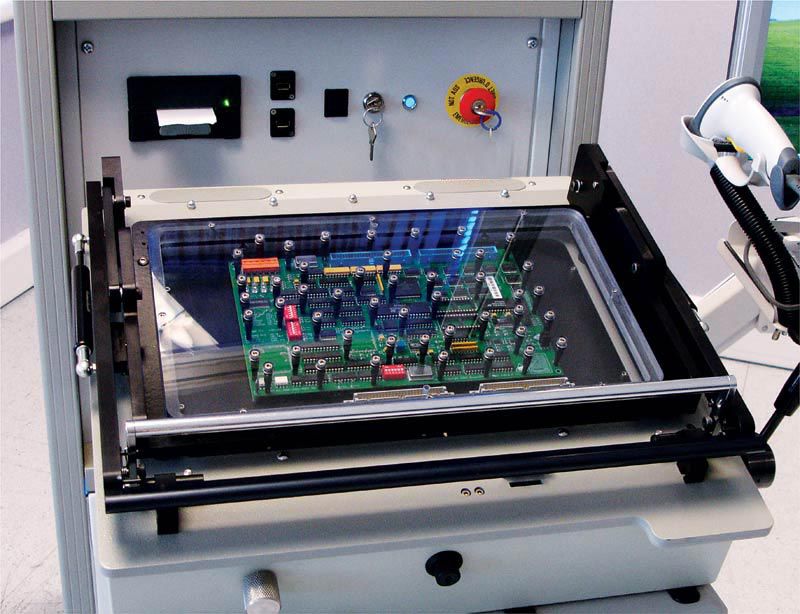

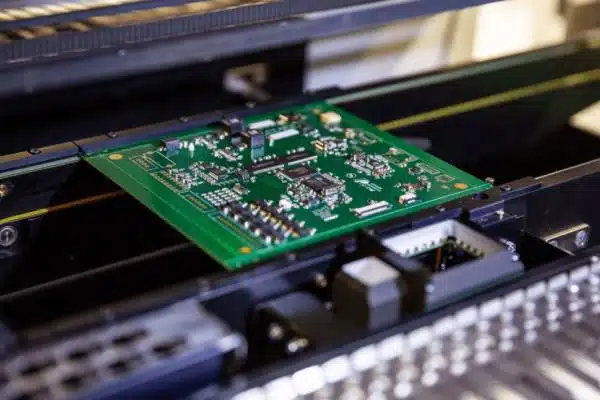

Automated Test Equipment PCB Manufacturing for High-Speed and High-Reliability Semiconductor Testing

In modern semiconductor manufacturing, Automated Test Equipment (ATE) plays a critical role in verifying the performance, reliability, and functionality of integrated circuits. At the core of every ATE system is the Automated Test Equipment PCB, which serves as the electrical interface between the test system and the device under test (DUT). An ATE PCB must...

As microwave and mmWave semiconductor technologies continue to evolve, accurate testing at GHz-level frequencies is essential. A Microwave IC Test PCB serves as a critical interface between microwave integrated circuits and automated test equipment (ATE), enabling precise signal transmission, impedance control, and reliable measurement results. These specialized test PCBs are widely used in RF front-end...

With the rapid advancement of RF and wireless semiconductor devices, precise testing at high frequencies has become critical. An RF IC Test PCB provides the necessary electrical interface for high-frequency ICs during automated test equipment (ATE) validation, ensuring accurate signal transmission, impedance matching, and repeatable test results. RF IC test PCBs are widely used in...

As memory devices continue to evolve toward higher speed, higher density, and lower power consumption, precise testing becomes increasingly critical. A well-designed Memory Test PCB is essential for validating the performance, reliability, and functionality of DRAM, NAND Flash, and other memory ICs throughout development and production stages. Memory test PCBs provide the electrical interface between...

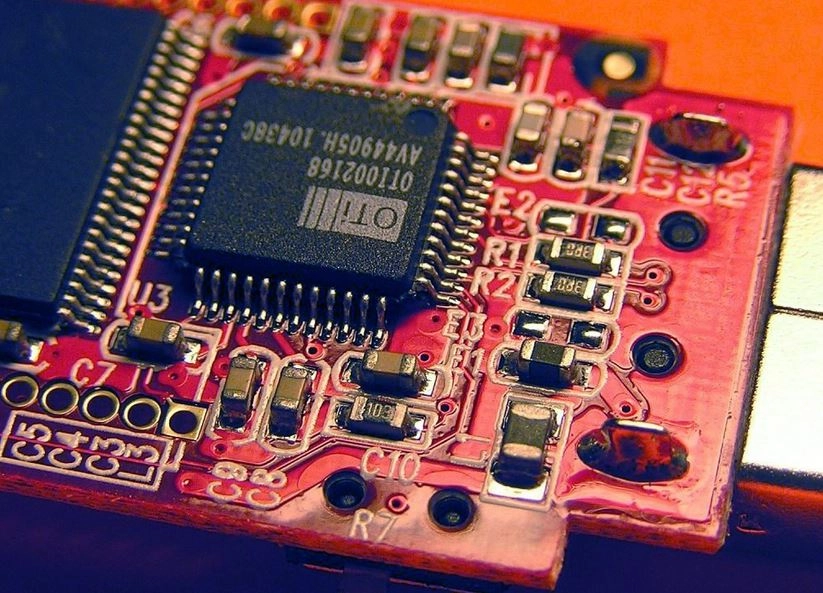

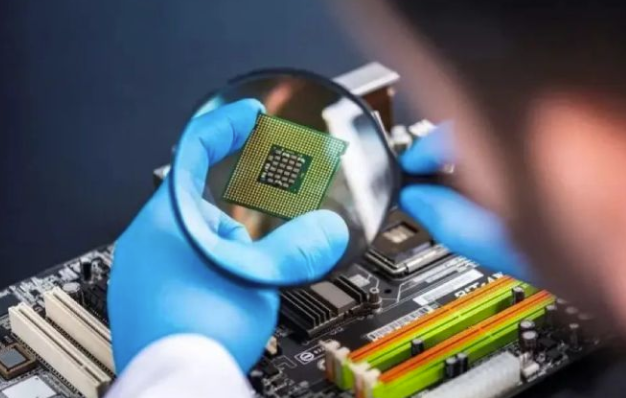

As semiconductor devices become faster, smaller, and more complex, accurate testing at the chip level is essential to ensure product performance and yield. A high-quality Chip Test PCB plays a critical role in IC validation by providing a stable and precise electrical interface between the chip under test and automated test equipment (ATE). Chip test...

In semiconductor manufacturing, wafer testing is a critical step performed before packaging to verify die functionality and performance. A high-quality Wafer Test PCB serves as the electrical interface between the wafer probe card and automated test equipment (ATE), enabling precise signal transmission and accurate measurement results. As IC designs continue to scale in speed, density,...

As integrated circuits become more complex and performance-driven, IC testing PCB plays a critical role in ensuring functionality, reliability, and yield throughout the semiconductor lifecycle. From early-stage IC validation to high-volume production testing, IC testing PCBs provide the electrical interface between the device under test (DUT) and automated test equipment (ATE). A high-quality IC testing...

In today’s fast-paced electronics industry, fast delivery PCB services are essential for companies facing tight development schedules, urgent testing requirements, or accelerated product launches. Whether for PCB prototypes, engineering validation, or short-run production, fast delivery PCBs help engineers reduce time-to-market without sacrificing quality. A reliable fast delivery PCB manufacturer combines efficient engineering processes, advanced fabrication...