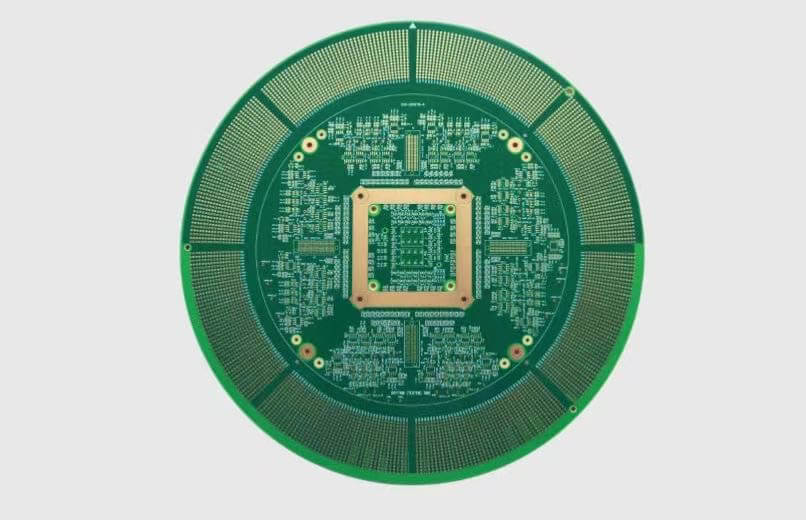

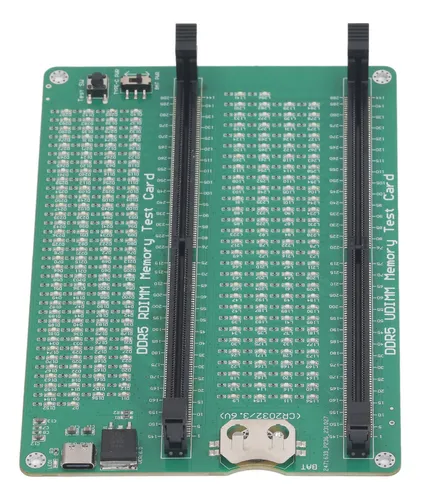

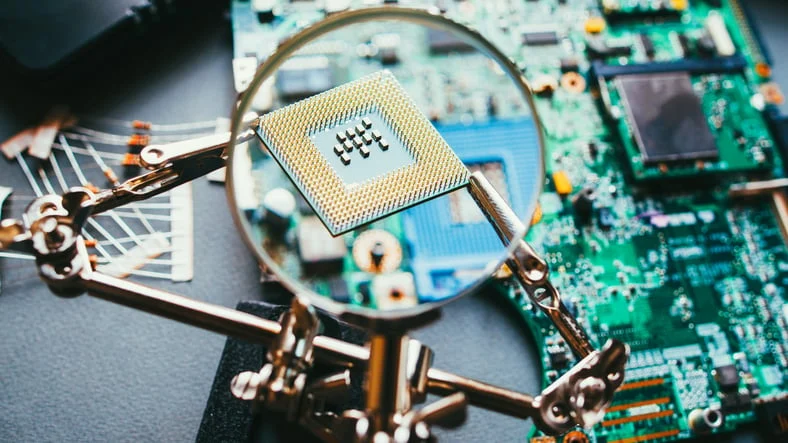

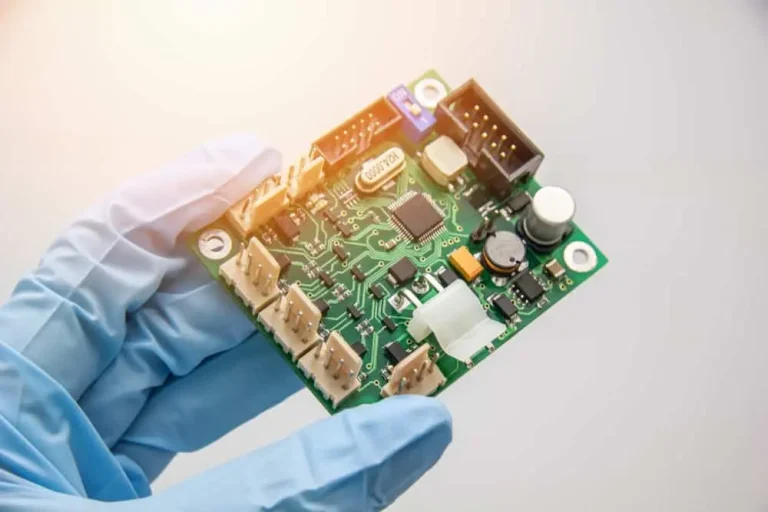

Test Socket PCB for IC: High-Precision PCB Solutions for Accurate Semiconductor Testing

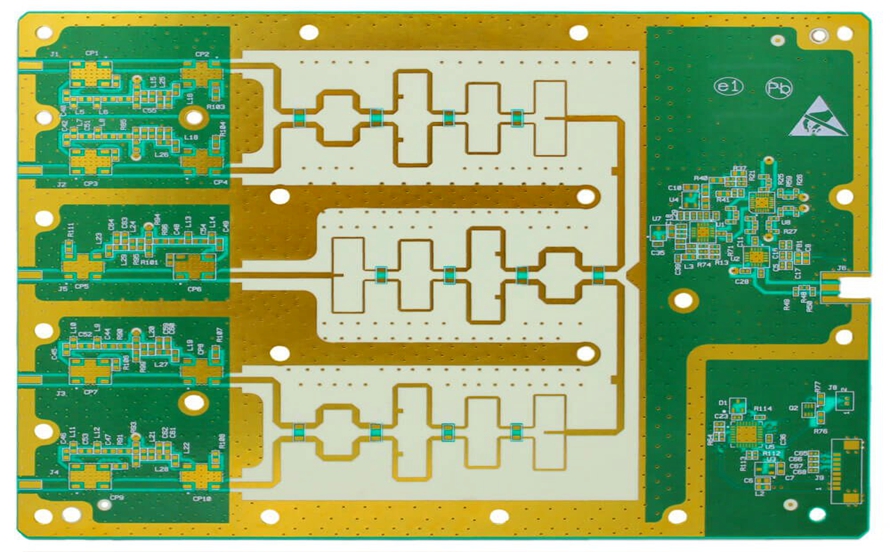

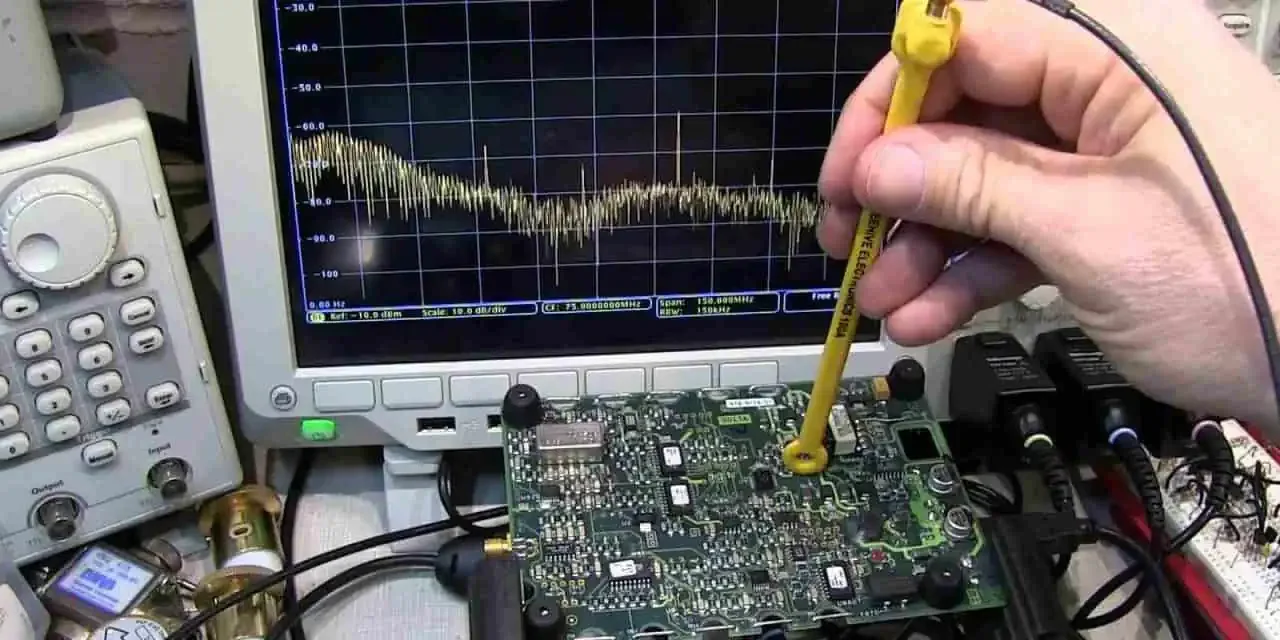

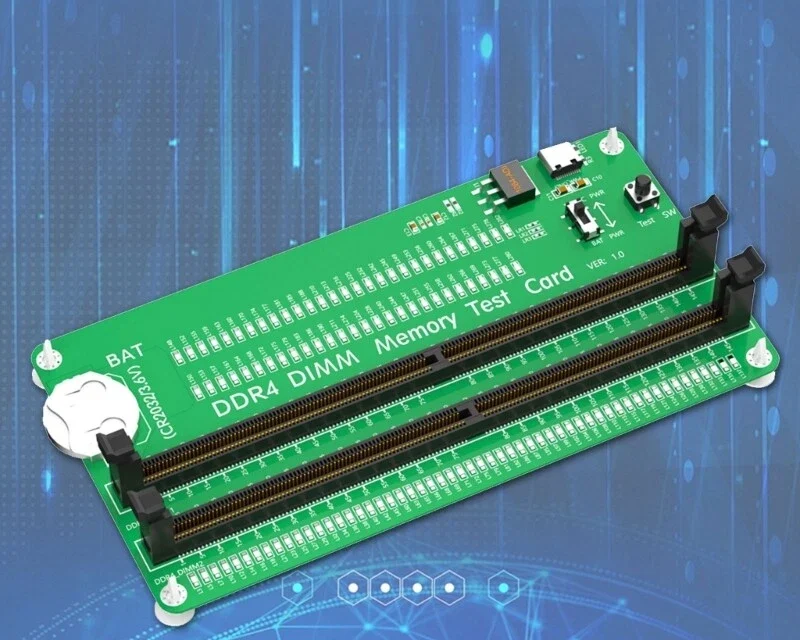

In modern semiconductor testing, the Test Socket PCB for IC is a critical interface between the device under test (DUT) and Automated Test Equipment (ATE). These PCBs enable accurate electrical contact, high-speed signal transmission, and mechanical stability, ensuring reliable IC, memory, and RF testing. As integrated circuits become more complex with higher pin counts, finer...