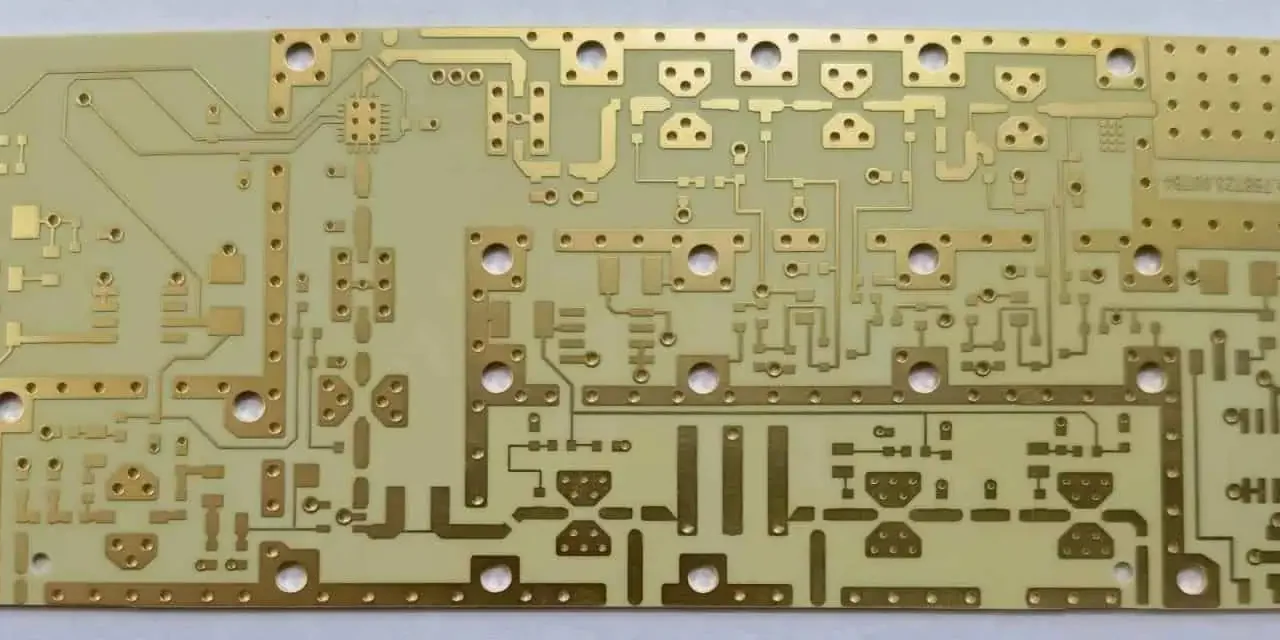

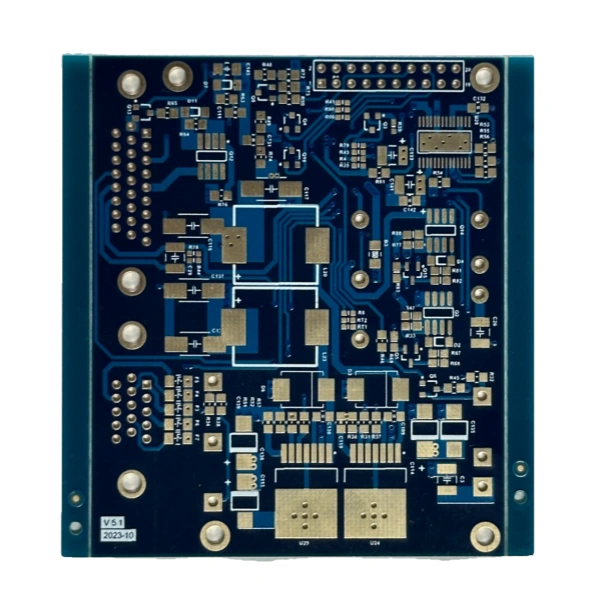

As RF and microwave systems continue to push into higher frequencies, material selection becomes a critical factor in circuit performance. The Duroid 6002 PCB is widely used in high-frequency designs where low loss, tight impedance control, and thermal stability are essential. Compared with standard FR-4, Duroid 6002 offers significantly improved electrical performance for demanding RF...

Blog

Explore the KKPCB Blog for the latest PCB manufacturing and assembly news, industry insights, expert tips, and technology trends, helping you stay informed and optimize your electronics projects.

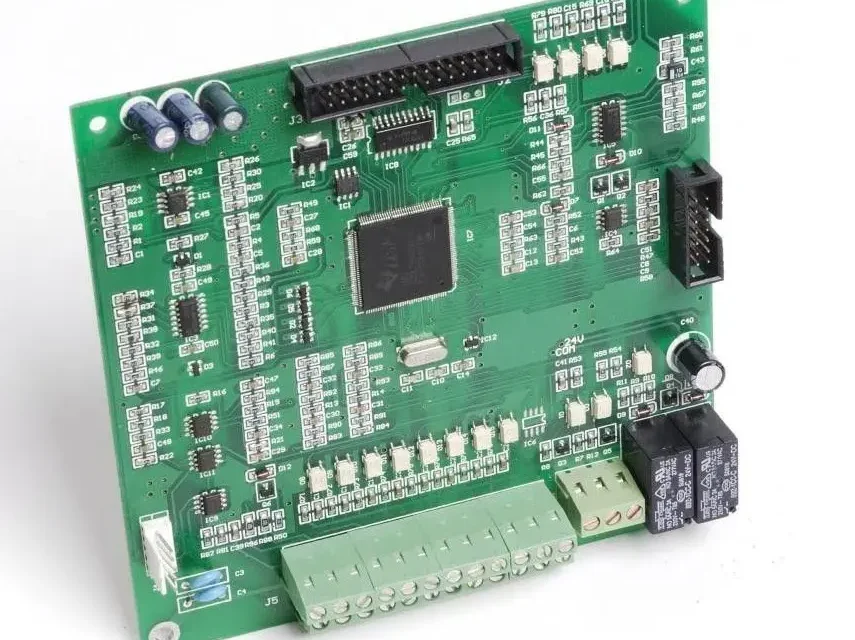

In semiconductor mass production, test throughput and consistency are just as important as accuracy. The Load Board PCB is a critical interface between automated test equipment (ATE) and packaged semiconductor devices, ensuring reliable electrical connection and repeatable test performance during high-volume production. A well-designed Load Board PCB minimizes downtime, reduces false failures, and supports long-term...

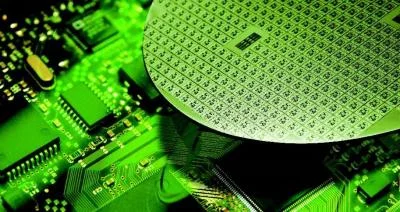

Semiconductor devices must pass multiple test stages before entering mass production and end-use applications. At every stage, the Semiconductor Test PCB plays a vital role in ensuring accurate measurement, stable operation, and repeatable test results. Whether used in wafer probing, package testing, or final system validation, a well-designed semiconductor test PCB directly impacts yield, reliability,...

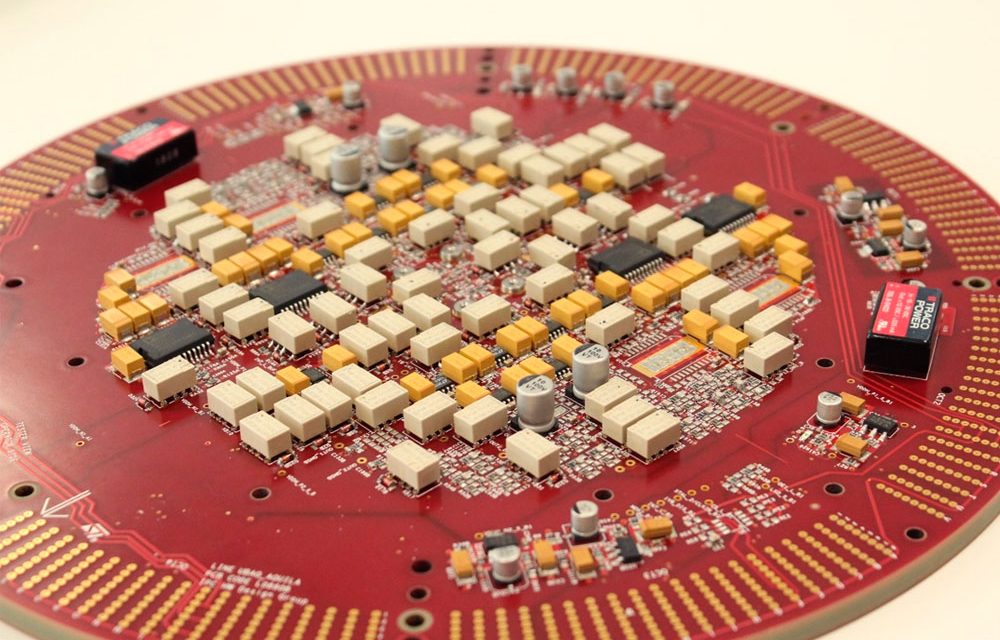

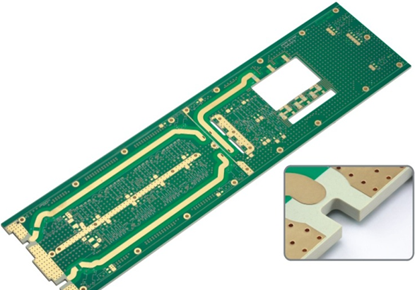

Wafer-level testing is one of the most demanding stages in semiconductor manufacturing. At this level, accuracy, repeatability, and mechanical precision are critical. The Probe Card PCB serves as the core platform that connects automated test equipment (ATE) to semiconductor wafers, enabling precise electrical contact and reliable signal transmission during wafer probing. A high-quality Probe Card PCB...

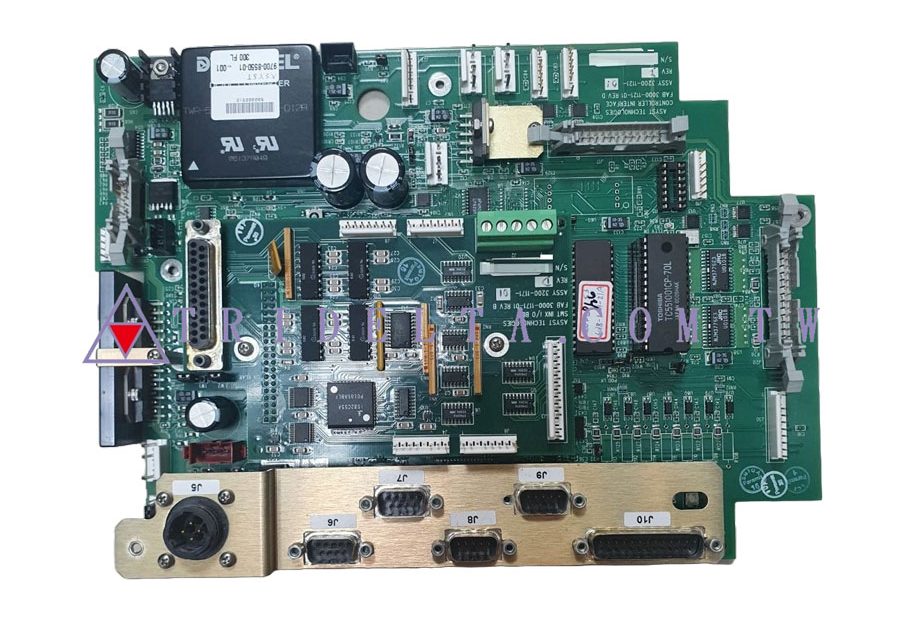

Automated Test Equipment (ATE) is the backbone of modern semiconductor validation and mass production. At the center of every ATE system is the ATE Test PCB, which directly affects test accuracy, yield stability, and long-term reliability. A well-engineered ATE test PCB ensures that measured performance reflects the device under test—not limitations of the test hardware....

Automated Test Equipment (ATE) platforms are highly configurable, but their performance ultimately depends on how well the test interface matches the device under test. A Custom ATE PCB is specifically designed to bridge this gap by aligning electrical, mechanical, and system-level requirements for accurate and repeatable semiconductor testing. Unlike off-the-shelf boards, a custom ATE PCB...

Testing high-frequency circuits is fundamentally different from testing standard digital electronics. At RF and microwave frequencies, even small PCB variations can introduce loss, phase error, or impedance mismatch that directly distort test results. The High Frequency Test PCB is specifically engineered to provide a stable and predictable platform for accurate RF measurement and validation. A...

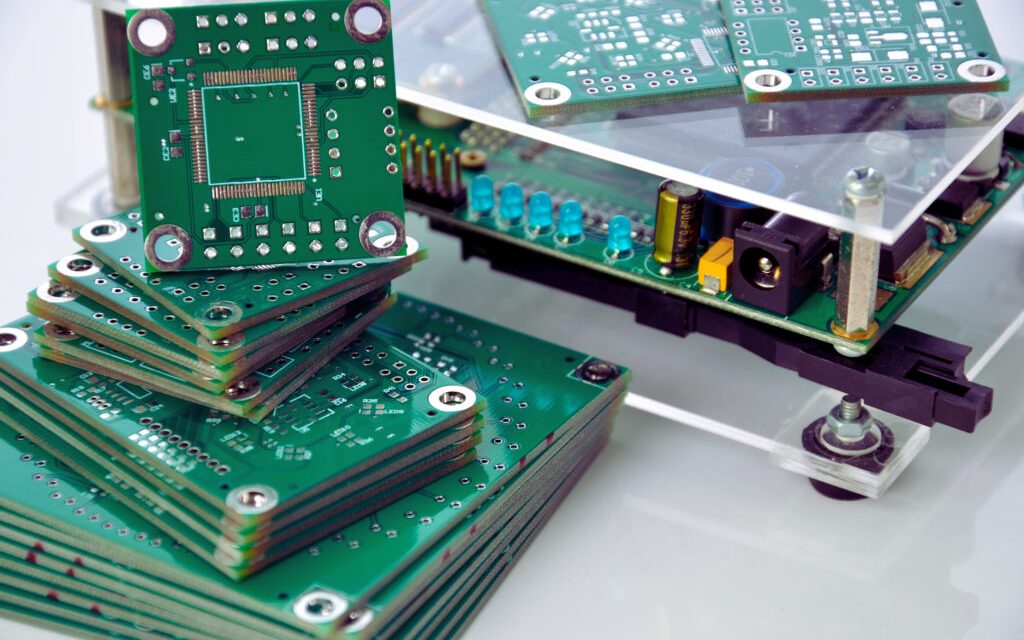

As electronic devices and semiconductor systems grow more complex, test requirements evolve beyond what simple PCB structures can support. The Multilayer Test PCB provides the routing density, electrical isolation, and power stability required for accurate, repeatable testing across development and production stages. A professionally engineered Multilayer Test PCB ensures that test results remain consistent as...

As electronic devices become smaller, faster, and more complex, traditional PCB technologies often reach their physical limits. HDI PCB (High Density Interconnect PCB) technology was developed to overcome these challenges by enabling higher wiring density, finer geometries, and improved electrical performance. A professionally manufactured HDI PCB is a key enabler for modern consumer electronics, communication...

High Pin Count PCB: Enabling Dense Interconnection for Advanced Electronic and Semiconductor Systems

As electronic systems continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections continues to rise. The High Pin Count PCB is specifically engineered to manage thousands of interconnections while maintaining electrical integrity, mechanical reliability, and manufacturability. A professionally designed High Pin Count PCB is essential for modern...