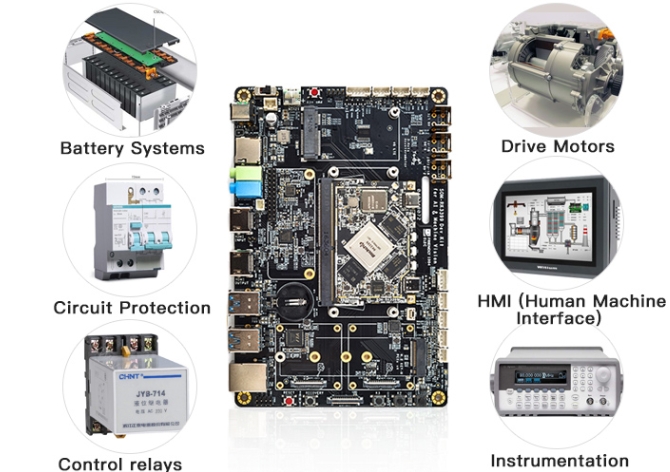

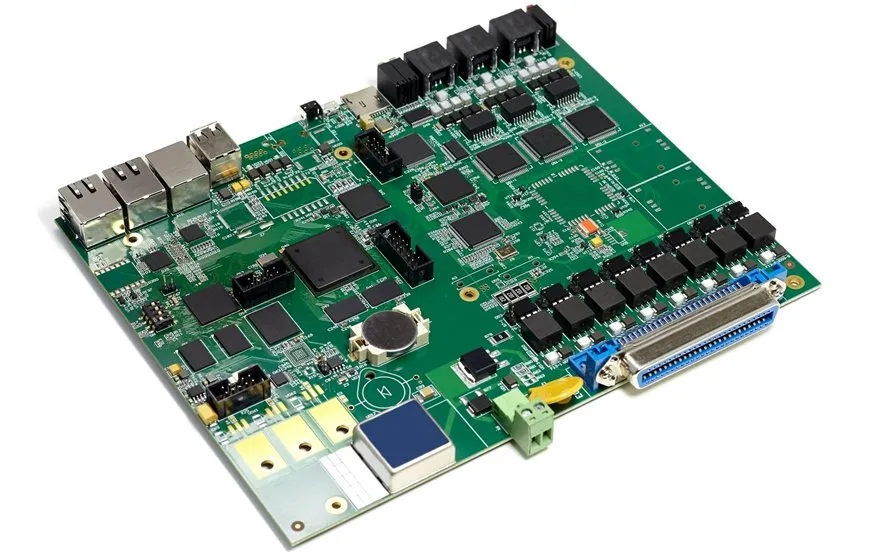

Due to the development of robotics and similar technologies, many different remote control devices are used in numerous fields. The assembly of printed circuit boards is essential for smooth movement and solid electrical connections between controllers and industrial machinery. Electronics must be rugged and able to withstand the harshest environments of industrial use. In addition, industrial control...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 8 of 75

PCB is one of the essential components and devices in electronics due to its wide availability and simplicity. Among the various types and forms of PCB, high-frequency PCB is widely used due to its general purpose. What is High-Frequency PCB? A high-frequency PCB is very similar to any other form of PCB (printed circuit board). It is compatible with...

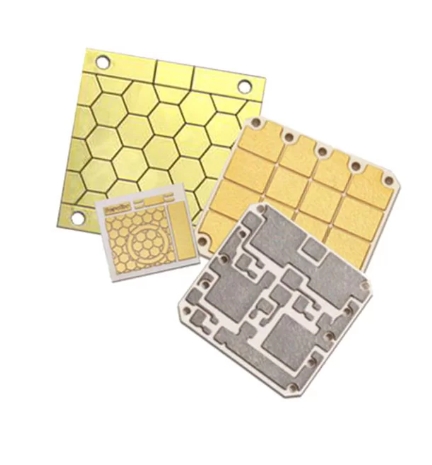

Among the numerous PCB options, two types are widely used. One is Ceramic PCB Substrate and the other is Alumina Substrate PCB. In this article, we will introduce the characteristics and advantages of each substrate in detail. Ceramic printed circuit boards are widely used in technology assembly due to their multiple characteristics and advantages. This type...

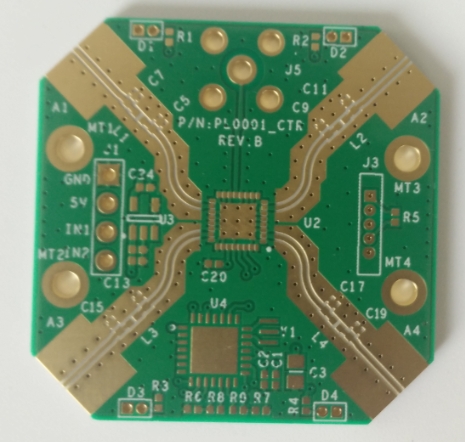

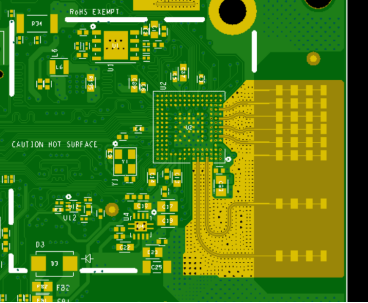

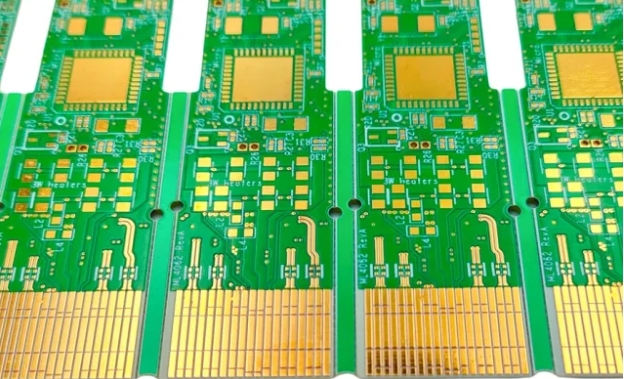

If you are new to the PCB industry, you may feel that PCBs look very similar. Can we identify the internal quality of PCBs by appearance? In fact, if there are slight differences in the appearance of PCBs, PCB industry experts can also identify the differences, and a good appearance is essential for the overall...

Customer Background The client specializes in the development and production of a wide range of microwave electronic products. These products are extensively used in satellite communication, television broadcasting, long-range communication, data and image transmission, radar, remote control, remote sensing, electronic reconnaissance, and electronic countermeasures. With deep technical expertise in microwave technology and high-frequency electronic products,...

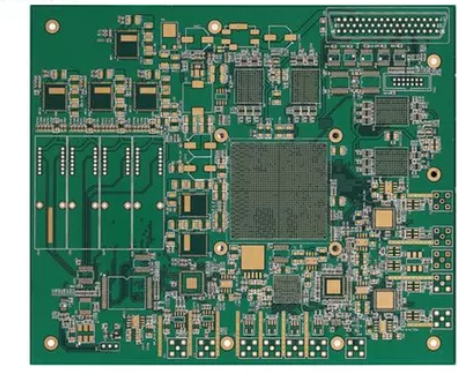

PCB assembly is a crucial step to ensure any new device is fully functional and productive. Engineers first build and test a prototype on a breadboard or computer. The prototype is then assembled and tested on the layout. Adjustments are made based on the test results, and once finalized, the product goes into production. In the...

The Printed Circuit Board (PCB) is a fundamental component of all electronic devices, serving as the “command center” that ensures their functionality. However, many business owners struggle to differentiate between PCB manufacturing and PCB assembly, often leading to suboptimal decisions. This article clarifies the distinction and importance of both processes. What is PCB Manufacturing? PCB manufacturing is the process of creating...

High-frequency PCBs are specialized circuit boards designed to transmit signals over a gigahertz (GHz) frequency range, ensuring quick and reliable communication in devices ranging from military radar systems to smartphones. These boards maintain signal integrity even at high frequencies, which is crucial for the functionality and efficiency of modern electronic devices. Stick around, and let’s explore...

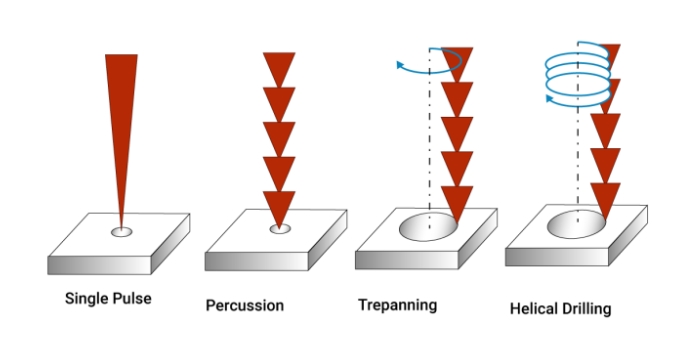

Staggered vias are a crucial element in the world of printed circuit board (PCB) design, especially for high-density interconnect (HDI) boards. But what exactly are they? Why are they important? Let’s take a deep dive into staggered vias and their benefits. What Are Staggered Vias? Staggered vias are tiny holes drilled at an offset across different layers of a...

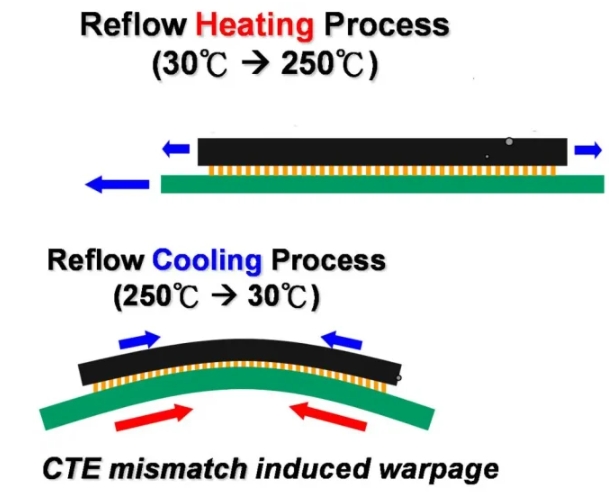

When designing and manufacturing Printed Circuit Boards (PCBs), one common yet often overlooked issue is warpage. Warping occurs when the PCB bends or twists, leading to alignment issues during assembly. This deformation can cause misalignment of components, poor solder joints, and even failure of the final product. In this article, we will explore what causes PCB warpage,...