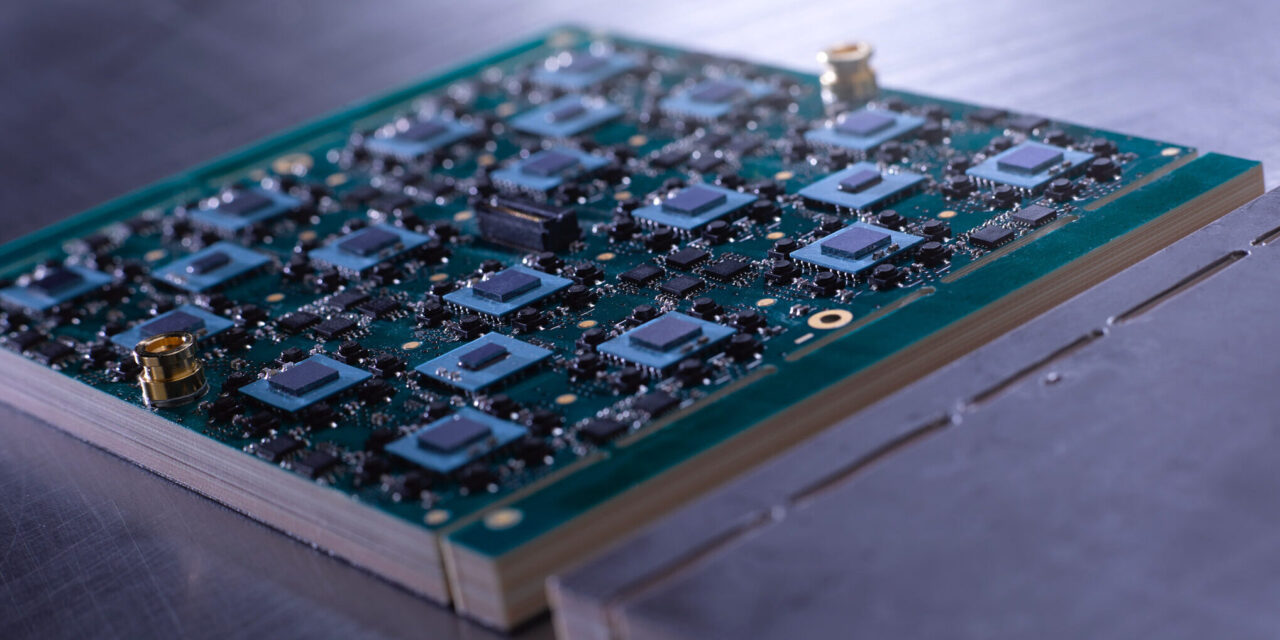

—Breakthroughs in Millimeter Wave PCB Processing Technology and Production Efficiency Contact: sales@kkpcb.com 1. Project Background Industry: Satellite Communications/Military Radar Application Scenario: 256-channel phased array antenna system (28GHz Ka-band) Customer requirements: ±60° beam steering, ±0.5dB amplitude consistency, 8-week delivery 2. Customer Pain Points & Manufacturing Challenges Challenge Category Original Design Issues KKPCB Manufacturing Solutions Process Compatibility...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 58 of 75

1. Customer Requirements & Background Industry: Defense Electronics End Applications: Armored vehicle main control units Field communication relay equipment Manufacturing Challenges: Heterogeneous material processing (AlSiC metal substrate + FR4 multilayer hybrid lamination) Extreme environment reliability (MIL-STD-810H vibration compliance) Military-grade quality control (100% inspection + batch traceability) Previous Supplier Pain Points: ✔ AlSiC substrate yield only 65% (delamination due to...

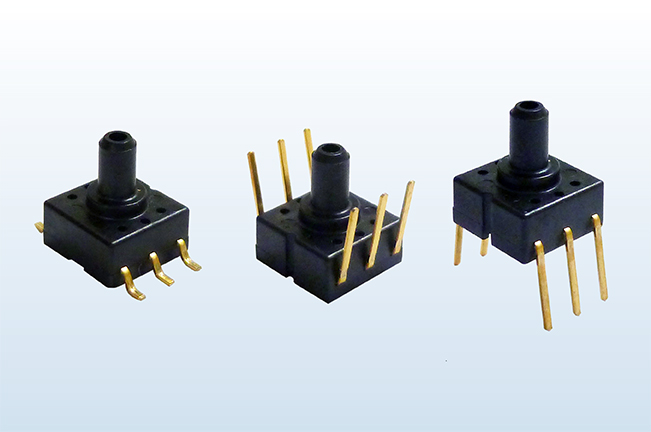

1.Background Overview A client from Europe, engaged in the development of industrial automation systems, required integration of a high-precision pressure sensor module in their next-generation process control system. The module needed to detect subtle changes in gas or liquid pressure in real time to enable dynamic control and safety alerts. Given the complex environment in...

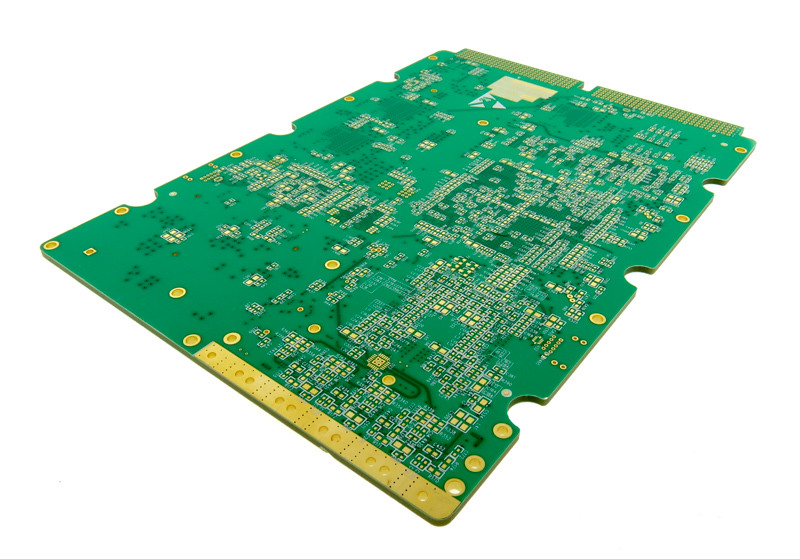

Client Industry: European Industrial Equipment Manufacturer Applications: Particle Accelerator RF Systems / Industrial Microwave Heating 1. Industry Manufacturing Challenges Critical Requirements: Sustain 100A+ high-frequency current (13.56MHz) Maintain MOSFET junction temperature <135°C in 85°C ambient Achieve 10-year maintenance-free operation Previous Supplier Issues: ▶ CTE mismatch in traditional aluminum substrates caused copper layer delamination ▶ Manual MOSFET soldering led...

Client Industry: European EMC Testing Equipment Manufacturer Applications: ISO 17025-Certified Probe Calibration / High-Frequency Field Measurement 1. Manufacturing Challenges Critical Requirements: Maintain dielectric thickness tolerance ±2% across 150mm×150mm panels (18GHz applications) Control Dk temperature drift within ±0.02 (-40°C to +85°C) Achieve 100% electrical parameter consistency for laboratory-grade calibration Previous Supplier Limitations: ▶ Manual thickness compensation caused ±8% dielectric variation ▶ PTFE delamination during lamination...

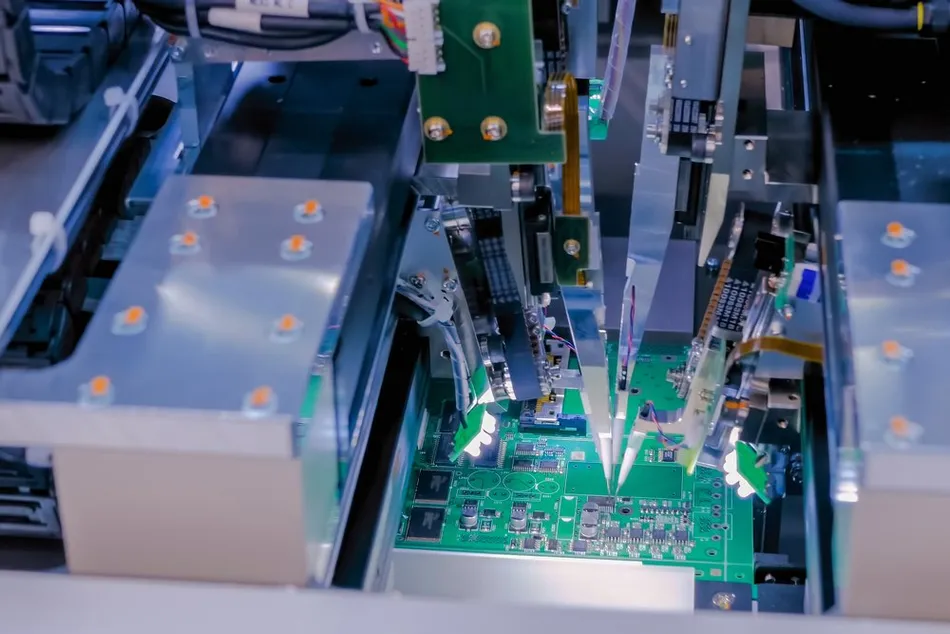

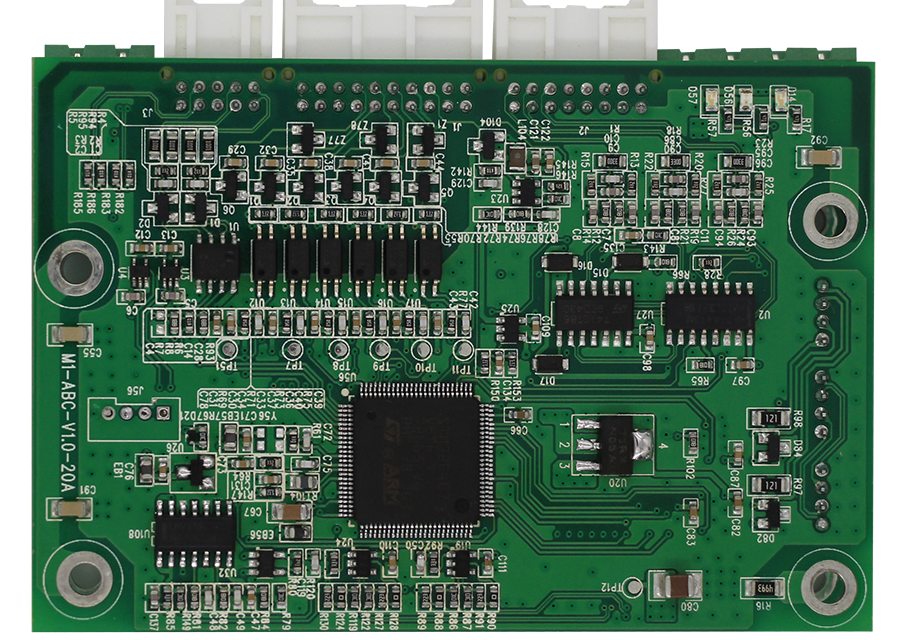

— High-Performance Drive Control Board Empowering Industrial Control Systems 1. Background Overview A customer from the Middle Eastern region, engaged in industrial control system integration, planned to develop a two-phase open-loop stepper motor driver for use in precision mechanical control applications. The project required a control board (PCBA) with high stability, strong interference resistance, precise microstepping control,...

Client: A Leading Metro System Operator (Asia) Application: Underground Tunnel Communication Systems 1. Operational Challenges Environmental Conditions: 24/7 high humidity: 95% RH (Relative Humidity) Condensation cycles with temperature fluctuations (15°C–45°C) Continuous vibration from passing trains Critical Failures Observed: ▶ Insulation resistance (IR) dropped to <1GΩ within 6 months ▶ Bit Error Rate (BER) surged to 10⁻⁴ (vs....

—Ultra-High-Density Design & Thermal Management for Compact Servo Systems 1. Customer Requirements Application: Industrial robotic joint drive control Key Challenges: Integrate 16-channel PWM control + current sampling within 80mm × 60mm Excessive MOSFET temperature rise (>30°C @20A), causing throttling Compliance with IEC 61000-6-4 (Industrial EMC Standard) 2. KKPCB Innovative Solution (1)Ultra-High-Density Interconnect Design 10-layer any-layer HDI (1+N+1 stackup), 0.1mm laser microvias, enabling 5μm trace/space Hybrid...

Discover how KKPCB delivered a high-reliability servo drive PCBA for a European industrial automation client. Featuring 6–8 layer HDI PCB fabrication, high-TG materials, ENIG finish, optimized thermal design, controlled impedance routing, copper-block heat management, and full SMT + DIP assembly. Achieved 45% EMI improvement, 30%+ uptime increase, <0.2% repair rate, and 12% cost reduction.

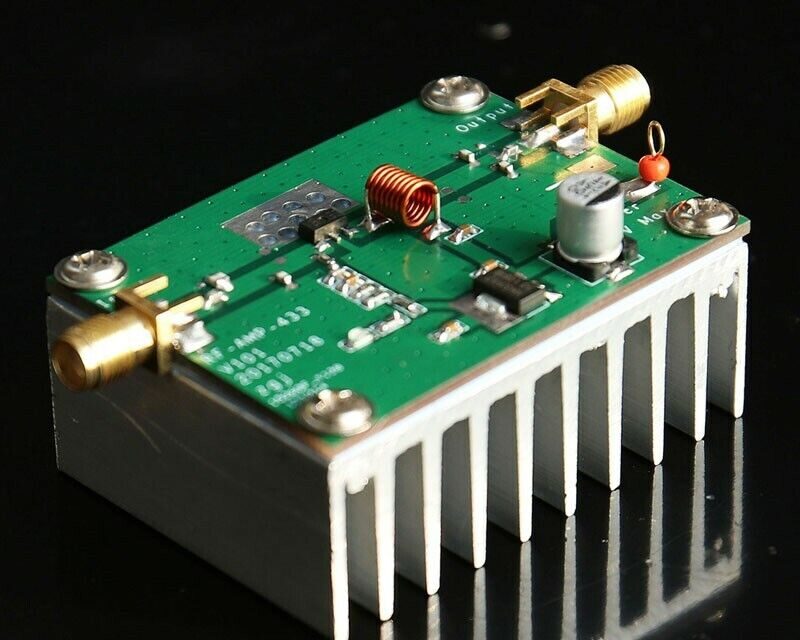

——High-Efficiency Design Solving Thermal Challenges in RF Applications 1. Customer Challenge Application: 5G Base Station/Radar Power Amplifier Pain Points: Low Efficiency: Only 35% at 6GHz, causing excessive heat Unstable Performance: Return loss > -15dB, signal reflection issues Material Limitations: FR4-only PCB led to dielectric loss (Df > 0.02 @10GHz) 2. KKPCB Breakthrough Solution (1)Hybrid Material Stackup Rogers RO4350B (top/bottom)...