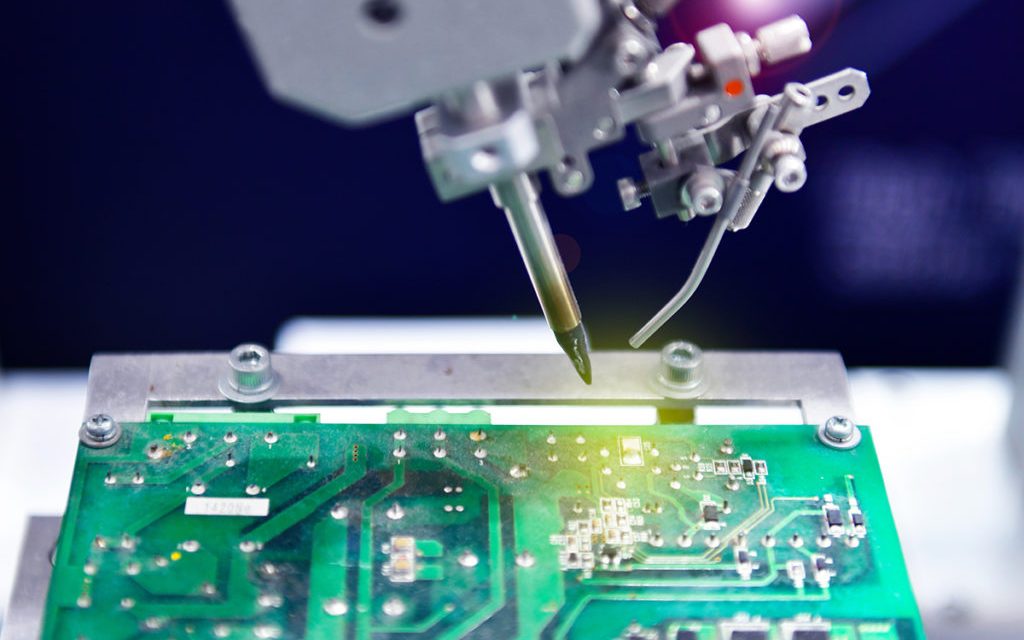

In automated test environments, PCB fabrication alone is not enough. The performance of an ATE system heavily depends on the quality of ATE PCB Assembly, where component placement accuracy, solder integrity, and process control directly affect test stability and yield. A professionally executed ATE PCB assembly ensures that the test board performs consistently across long...

HomeTag

Turnkey PCB Assembly - KKPCB

Why PCB Turnkey Matters in Modern Electronics Manufacturing As electronic systems become more complex, managing separate suppliers for PCB fabrication, component sourcing, assembly, and testing introduces cost risk, schedule delays, and quality uncertainty. This is especially true for products involving high-speed digital signals, RF circuits, power electronics, or mixed-technology assemblies. PCB turnkey solutions address this...

What Is PCB Turnkey? PCB Turnkey refers to a one-stop PCB solution where a single manufacturer manages the entire process—from bare PCB fabrication and electronic component procurement to assembly, testing, and logistics. Instead of coordinating multiple suppliers, customers work with one partner who takes full responsibility for quality, schedule, and delivery. At KKPCB, PCB Turnkey...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

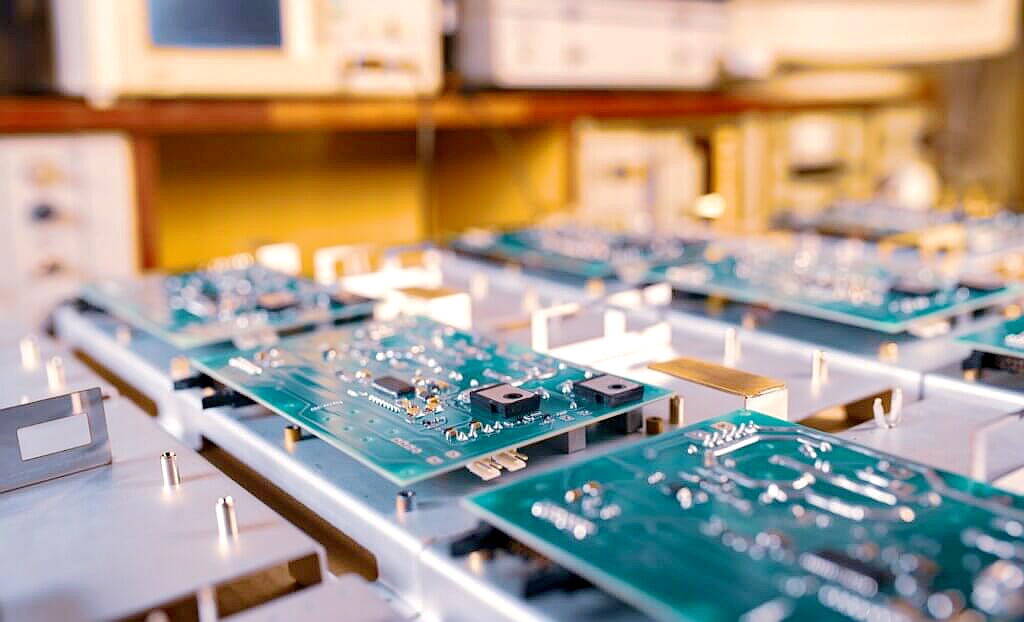

PCB Turnkey Solutions for Integrated Design, Fabrication, Assembly, and Supply Chain Management

PCB Turnkey: A Complete Engineering-Driven Manufacturing Model PCB Turnkey refers to a fully integrated manufacturing solution that covers PCB fabrication, component sourcing, PCB assembly, functional testing, and logistics delivery under a single engineering-managed workflow. Unlike fragmented outsourcing models, PCB Turnkey services eliminate interface risk between suppliers and significantly improve quality consistency, lead time predictability, and...