What Is a High Current PCB? A High Current PCB is a printed circuit board specifically designed to carry large currents while maintaining electrical stability and thermal reliability. These PCBs are commonly used in power electronics, automotive inverters, industrial automation, renewable energy systems, and high-current semiconductor testing. High current PCBs typically feature thick copper layers,...

HomeTag

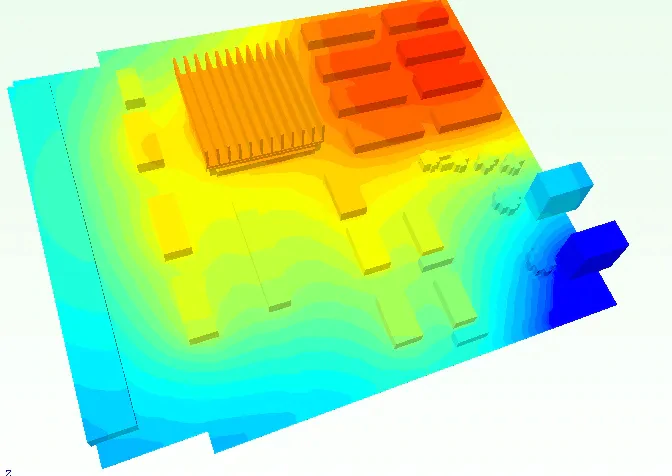

thermal management PCB - KKPCB

As electronic devices become more compact and powerful, effective Thermal Management PCB solutions are critical to ensure performance, reliability, and product lifespan. High-power components such as CPUs, power MOSFETs, IGBTs, LEDs, and RF amplifiers generate significant heat during operation. Without proper PCB thermal management, excessive temperature rise can lead to signal instability, reduced efficiency, and...

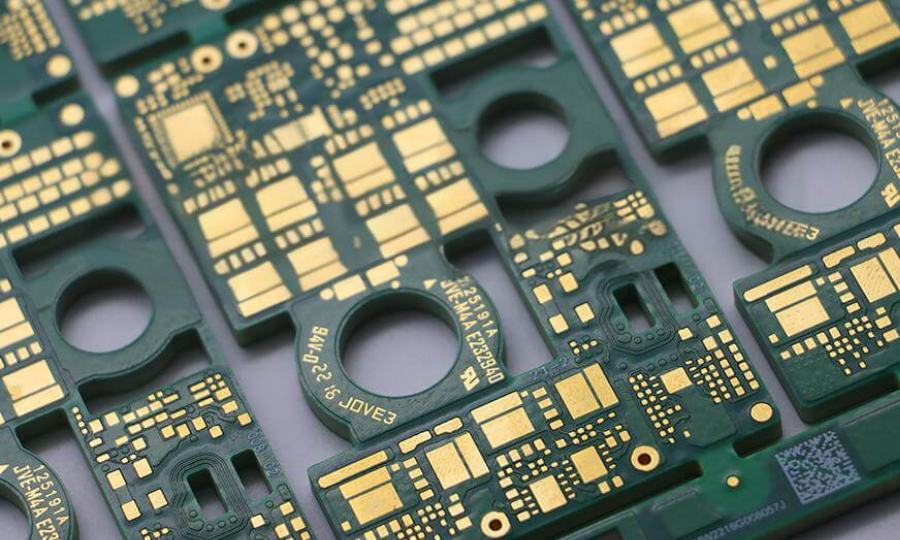

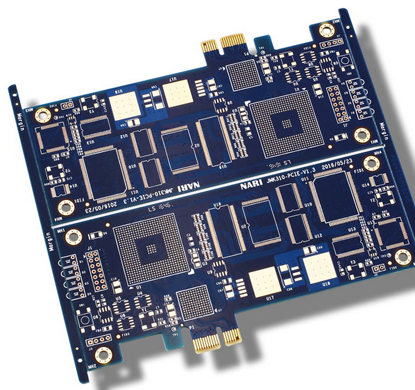

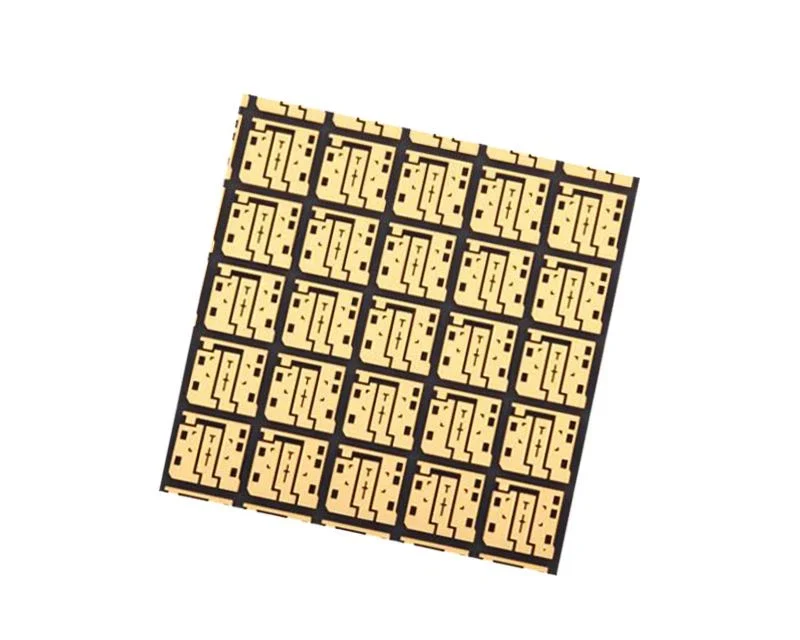

What Is a Heavy Copper PCB? A Heavy Copper PCB is a printed circuit board manufactured with thick copper layers, typically ranging from 3 oz to over 20 oz per square foot, to support high current, high power, and enhanced thermal performance. Compared with standard PCBs, heavy copper PCBs provide lower resistance, better heat dissipation,...

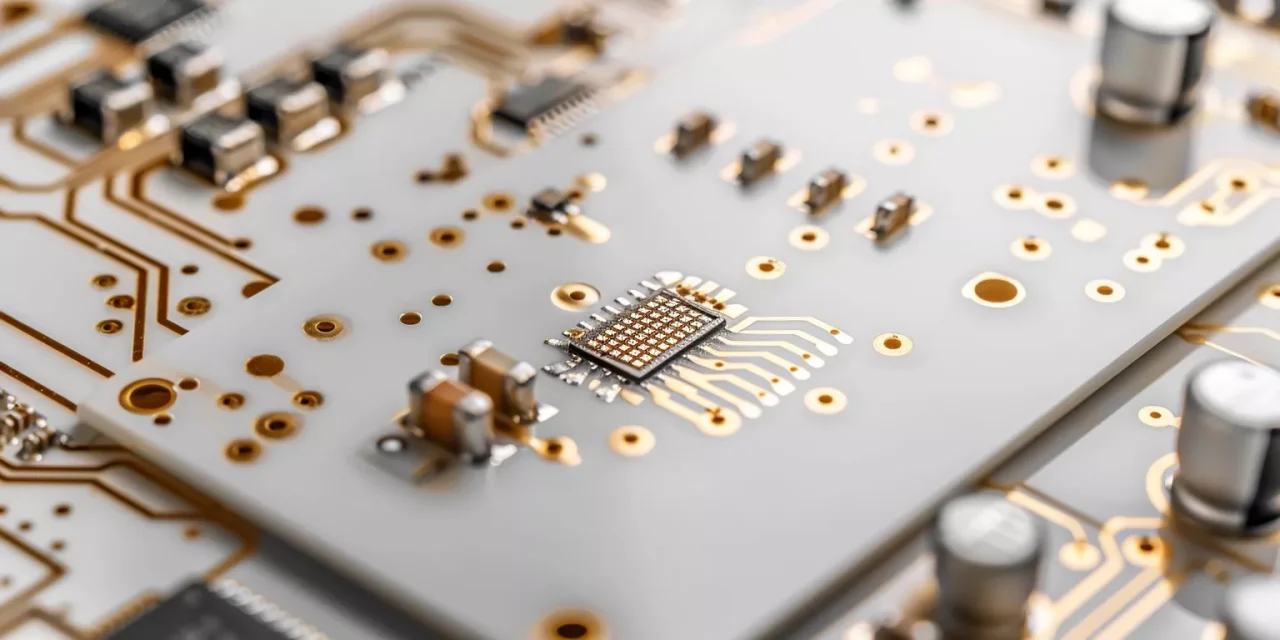

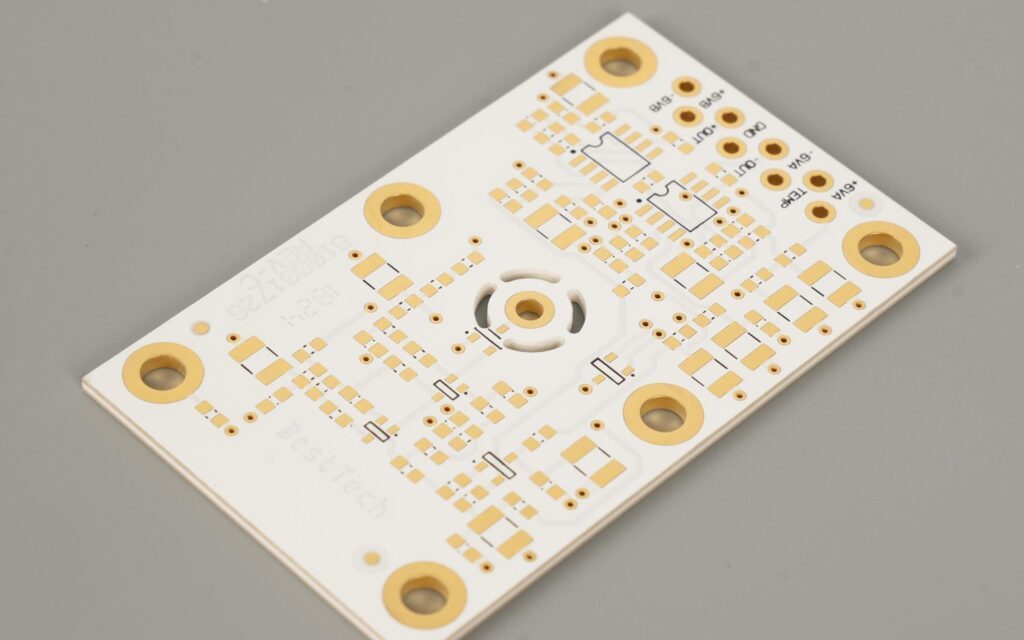

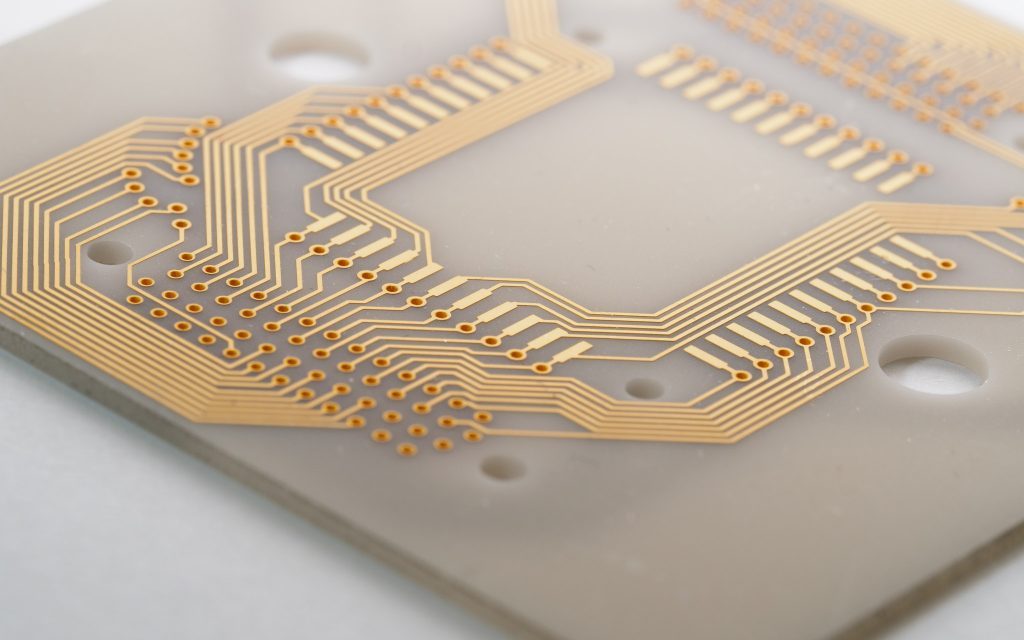

What Is Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Alumina ceramic PCBs are widely used in high-power, high-temperature, and high-reliability electronic applications due to their excellent thermal conductivity, electrical insulation, and mechanical strength. Compared with traditional FR-4 PCBs, Alumina PCBs provide superior...

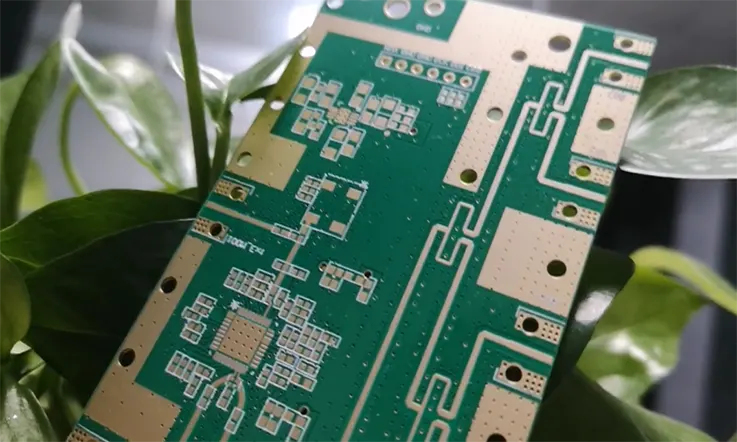

What Are Hybrid PCB Materials? Hybrid PCB materials refer to printed circuit boards made from a combination of two or more substrate types, such as FR-4, metal-core, PTFE, or ceramic, to achieve specific electrical, thermal, or mechanical properties. Hybrid PCB materials are widely used in advanced PCB designs, where a single material cannot meet all...

Hybrid PCB materials combine two or more substrate types—such as high-speed laminates, low-loss materials, BT epoxy, and ceramics—to create boards optimized for electrical performance, thermal management, and mechanical stability. Unlike single-material PCBs, hybrid designs allow engineers to tailor material properties to different areas of the circuit, achieving performance levels unattainable with conventional laminates. Why Hybrid...

Hybrid PCB materials are engineered substrates that combine multiple material types to achieve optimized electrical, thermal, and mechanical performance in demanding electronic applications. By integrating properties of FR-4, high-frequency laminates, PTFE, or ceramic materials, hybrid PCBs enable designers to meet multi-domain requirements that a single material cannot satisfy. Material Characteristics of Hybrid PCB Materials The...

An Aluminum Nitride PCB (AlN PCB) is a ceramic-based circuit substrate engineered for electronic systems that demand exceptional thermal conductivity, electrical insulation, and dimensional stability under high power density and elevated temperature conditions. In power electronics and high-reliability applications, material selection is not a secondary decision—it defines system performance limits. Material-driven Aluminum Nitride PCB design...

A Ceramic PCB is a high-performance circuit substrate engineered for applications that demand excellent thermal conductivity, electrical insulation, and long-term reliability under harsh operating conditions. Unlike organic PCB materials such as FR-4 or PTFE, ceramic PCB substrates are inorganic, enabling stable electrical and mechanical performance at elevated temperatures and high power densities. Ceramic PCB technology...

As modern electronics continue to evolve toward higher power density, smaller packaging, and harsher operating environments, thermal performance has become one of the most important factors in PCB material selection. In applications such as EV power modules, IGBT and MOSFET power stages, SiC/GaN devices, and high brightness LED modules, traditional FR-4 PCBs often cannot provide...