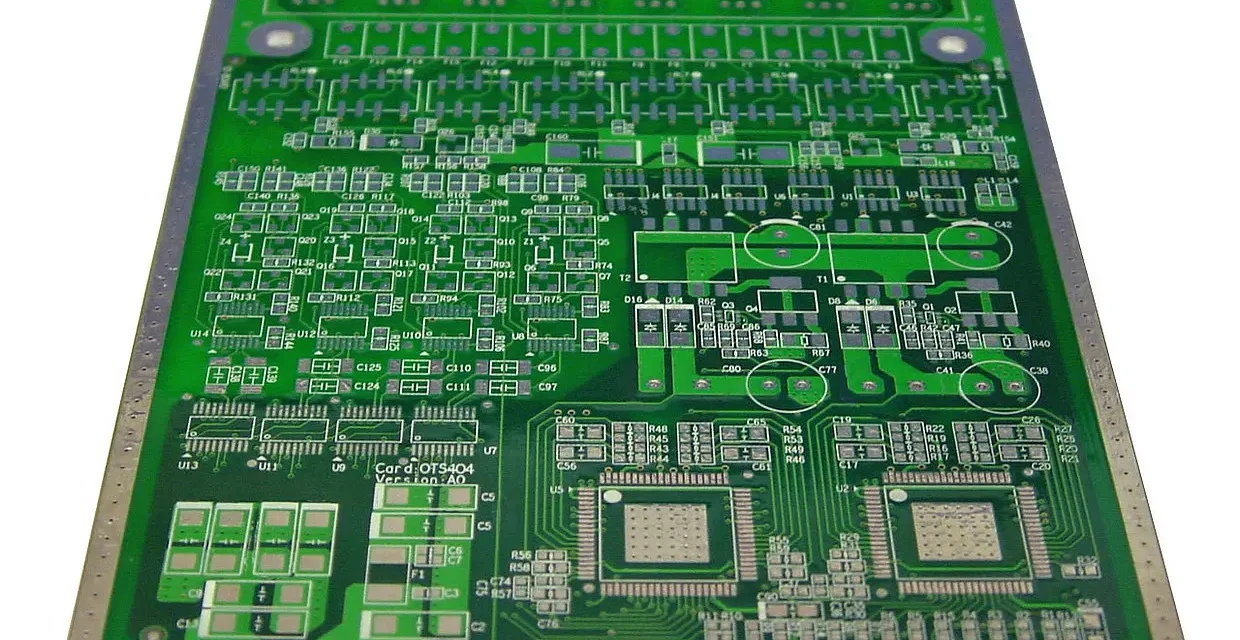

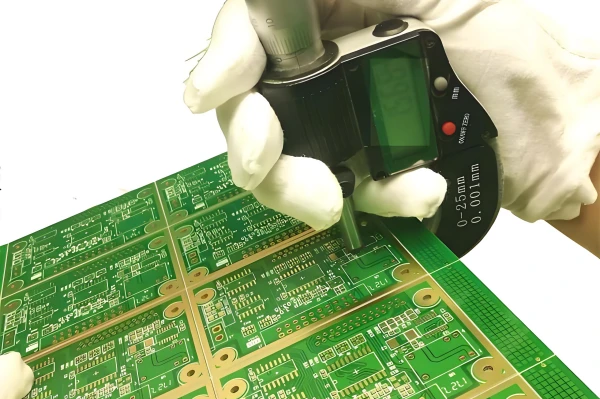

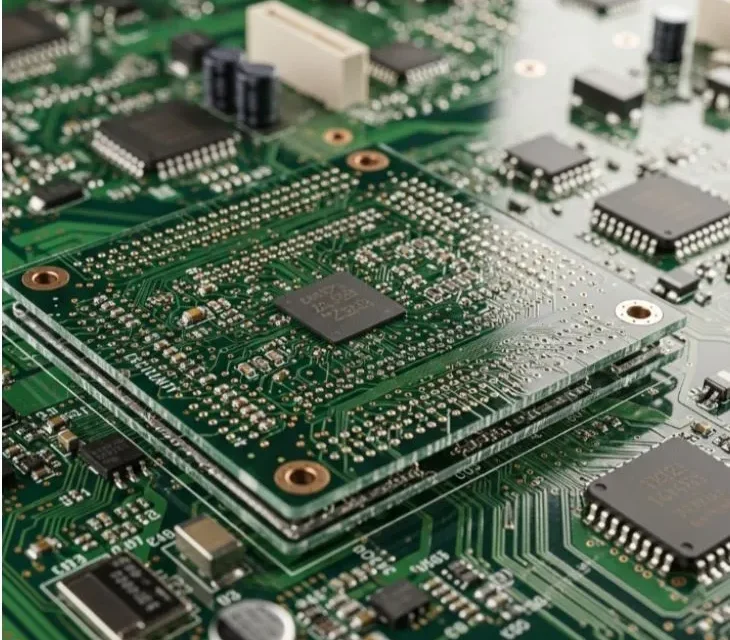

What Is a PCB Prototype Order? A PCB prototype order refers to the production of low-quantity printed circuit boards used for design verification, functional testing, and engineering validation before volume manufacturing. PCB prototype orders are a critical step in product development, R&D, and new product introduction (NPI). Compared with mass production, PCB prototype manufacturing prioritizes...

HomeTag

Small Batch PCB - KKPCB

What Is a PCB Prototype Order? A PCB prototype order refers to the fabrication (and optional assembly) of small-quantity printed circuit boards used to verify circuit design, functionality, and manufacturability before entering mass production. PCB prototype orders are a critical step in product development, R&D, and engineering validation. Compared with volume production, PCB prototype manufacturing...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Fast Delivery PCB: Accelerating Product Development with Rapid PCB Manufacturing

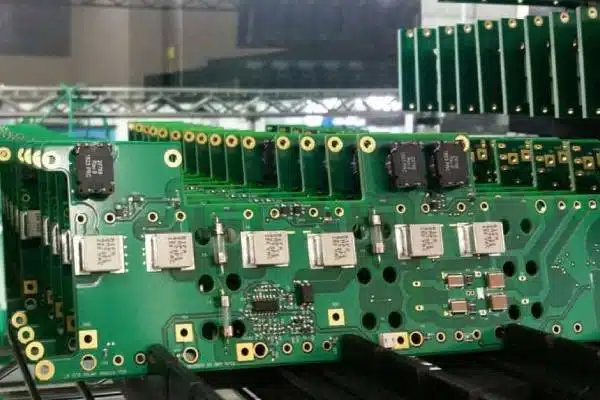

In today’s highly competitive electronics market, speed is often the key differentiator between success and missed opportunity. Fast delivery PCB services enable engineers, startups, and OEMs to shorten development cycles, validate designs faster, and respond quickly to market demands. Whether for early-stage prototypes, small-batch production, or urgent engineering revisions, fast delivery PCB manufacturing plays a...

In today’s fast-paced electronics and semiconductor industry, speed and reliability are critical. Engineers often need to validate designs quickly, iterate rapidly, and move from prototypes to production with minimal delay. Fast delivery PCBs provide the ideal solution by offering rapid prototyping, small-batch manufacturing, and high-quality boards that meet strict electrical and mechanical requirements. These PCBs...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB Assembly (PCBA)PCB DesignPCB ManufacturingPCB Materials

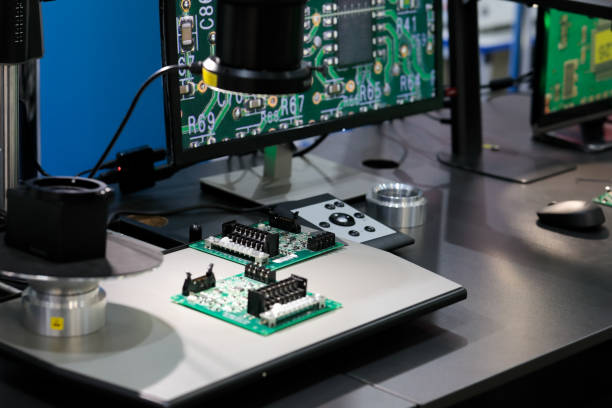

ATE PCB Prototype: Rapid Prototyping Solutions for Automated Test Equipment

In semiconductor and electronic testing environments, speed and accuracy are critical. ATE PCB prototypes play a key role in validating automated test equipment designs, allowing engineers to quickly evaluate signal integrity, mechanical fit, and electrical performance before full-scale production. Fast and reliable ATE PCB prototyping reduces development risk and accelerates time-to-market. What Is an ATE...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Fast Delivery PCB: Accelerate Prototyping and Production with Rapid PCB Services

In today’s fast-paced electronics market, time-to-market is critical. Fast delivery PCBs provide a solution for engineers and manufacturers who need quick turnaround without compromising quality. Whether for prototyping, small batch production, or urgent project deadlines, fast delivery PCB services help accelerate product development cycles and engineering iterations. What Is a Fast Delivery PCB? A fast...

In today’s fast-paced electronics industry, speed can determine market success. Fast delivery PCBs offer engineers and manufacturers the ability to accelerate prototyping, testing, and low-volume production without compromising quality or electrical performance. Fast delivery PCB services are essential for time-sensitive projects, including high-frequency, high-speed, and complex multilayer designs. What Is a Fast Delivery PCB? A...

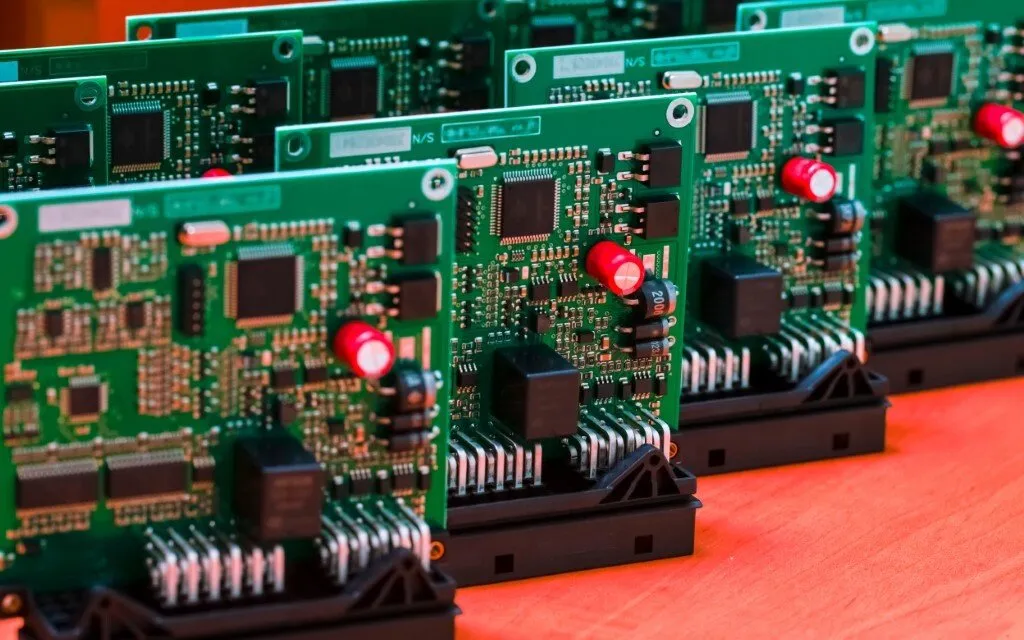

In today’s fast-paced electronics industry, rapid product validation and frequent design iterations are essential.small batch PCBmanufacturing provides an ideal solution for startups, R&D teams, and engineering groups that require high-quality PCBs without committing to large production volumes. This article explores what small batch PCB manufacturing is, why it matters, and how it supports efficient product...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Small Batch PCB Manufacturing: Enabling Flexible Engineering Validation and Low-Risk Product Development

Why Small Batch PCB Matters in Modern Electronics Development In today’s electronics industry, product lifecycles are shorter and design iterations are more frequent. Before committing to mass production, engineering teams must validate signal integrity, power stability, thermal behavior, and manufacturability. Small batch PCB manufacturing plays a critical role in this phase by enabling controlled, low-risk...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Small Batch PCB Manufacturing for High-Mix, Engineering-Driven Electronics Development

Small Batch PCB manufacturing refers to low-volume PCB production typically ranging from a few pieces to several hundred units, designed to support prototype validation, pilot runs, and early-stage product commercialization. Unlike mass production, Small Batch PCB emphasizes engineering accuracy, process flexibility, and rapid iteration over scale efficiency. For modern electronics development, Small Batch PCB is...