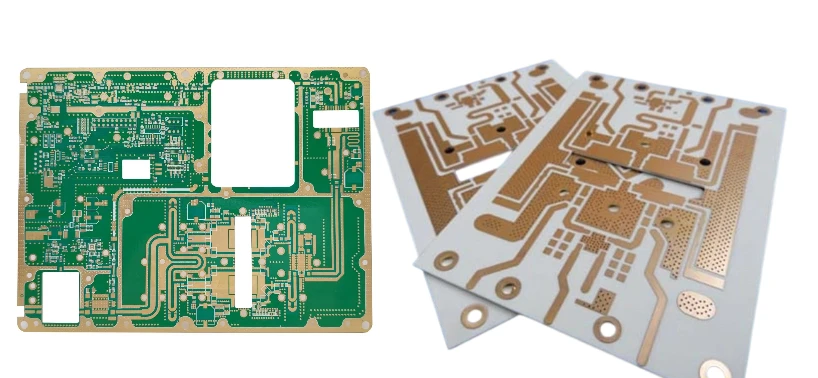

What Are Low Loss Materials? Low loss materials are specialized PCB laminate materials designed to minimize signal attenuation in high-speed and high-frequency circuits. Compared to standard FR-4 materials, low loss materials provide: Lower dissipation factor (Low Df) Stable dielectric constant (Dk) Reduced insertion loss Improved signal integrity Better high-frequency performance Low loss materials are essential...

HomeTag

signal integrity PCB - KKPCB

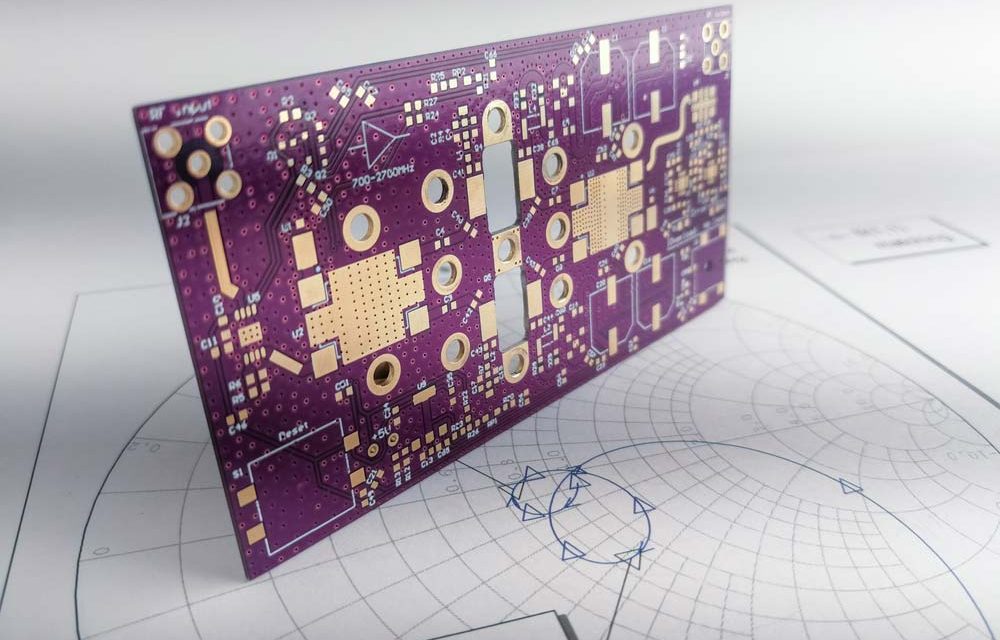

What Is an RO4003C PCB? An RO4003C PCB is a high-frequency printed circuit board manufactured using Rogers RO4003C laminate, a hydrocarbon ceramic-filled material specifically engineered for low loss RF and microwave applications. RO4003C PCBs are widely used in: RF and microwave circuits 5G base station modules Automotive radar systems Satellite communication equipment High-speed digital and...

What Is a PTFE PCB? A PTFE PCB is a printed circuit board made from polytetrafluoroethylene (PTFE) laminates, known for extremely low dielectric loss, stable dielectric constant, and excellent high-frequency performance. PTFE PCBs are widely used in 5G, mmWave modules, RF/microwave systems, aerospace electronics, and high-speed computing, where signal integrity and low insertion loss are...

What Is a Rogers PCB? A Rogers PCB is a printed circuit board that uses Rogers high-frequency laminates, such as RO4003C, RO4350B, and Duroid series, designed for low dielectric loss, precise impedance control, and high-frequency signal transmission. Rogers PCBs are essential in 5G communications, RF/microwave modules, high-speed computing, and aerospace electronics. Why Rogers PCB Technology...

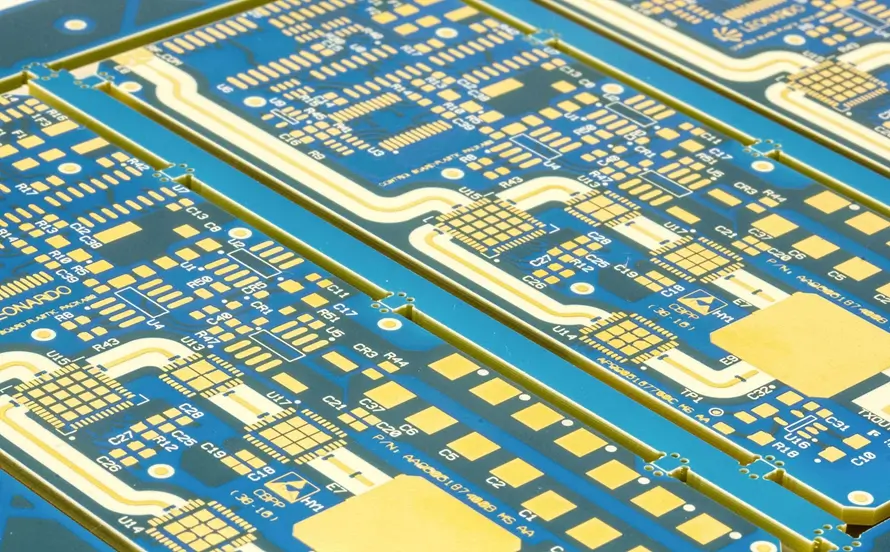

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to carry high-speed and high-frequency signals with minimal loss, reflection, or distortion. These PCBs are crucial in RF, microwave, 5G, high-speed computing, and semiconductor test applications, where signal integrity and low insertion loss are essential for system...

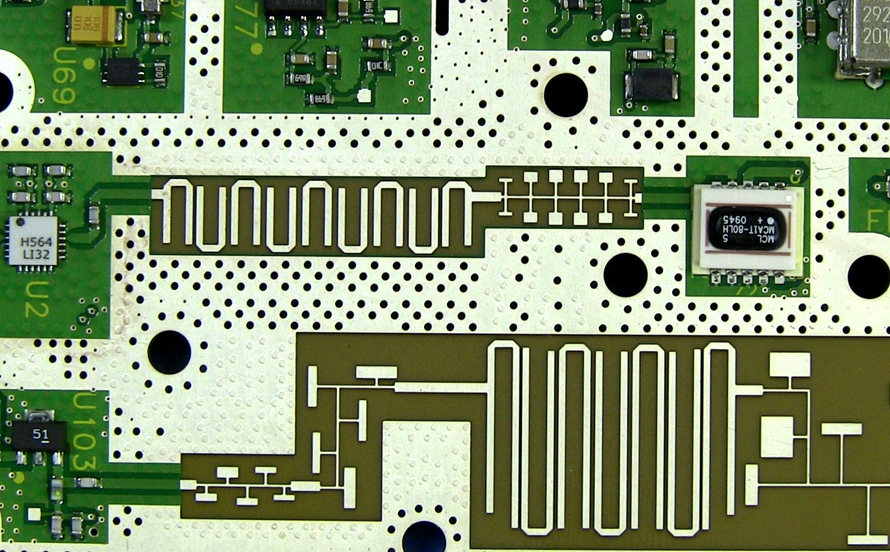

What Is an RF Trace PCB? An RF Trace PCB is a printed circuit board designed to route high-frequency RF signals with minimal signal loss, reflection, and distortion. These PCBs are optimized for controlled impedance, low insertion loss, and high signal integrity, making them essential for applications such as 5G modules, mmWave systems, wireless communication,...

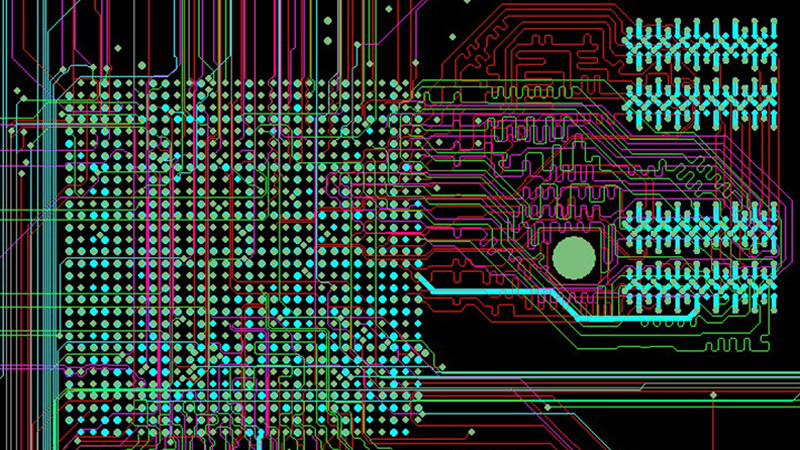

What Is a Differential Pair PCB? A Differential Pair PCB is a printed circuit board designed to route differential signal pairs, which are two complementary signals transmitted simultaneously to improve noise immunity, reduce crosstalk, and maintain signal integrity. Differential pair technology is critical in high-speed digital interfaces, such as USB, HDMI, PCIe, Ethernet, DDR memory,...

What Is a High Speed Logic PCB? A High Speed Logic PCB is a printed circuit board designed to support high-speed digital logic circuits, where signal rise times are extremely fast and timing accuracy is critical. These PCBs ensure minimal signal distortion, precise timing, and reliable data transmission for high-performance computing, telecommunication, and semiconductor testing...

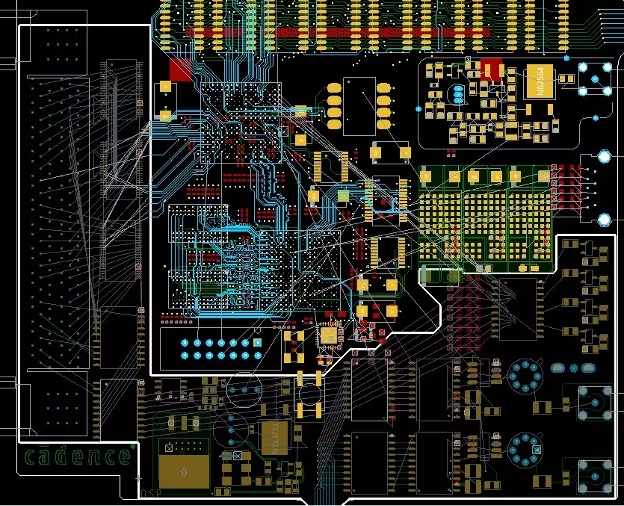

What Is a Signal Integrity PCB? A Signal Integrity (SI) PCB is a printed circuit board designed to maintain clean, stable high-speed signal transmission across digital, analog, or mixed-signal circuits. SI PCBs are essential for applications where data integrity, minimal signal distortion, and timing accuracy are critical, such as 5G communications, high-speed computing, automotive electronics,...

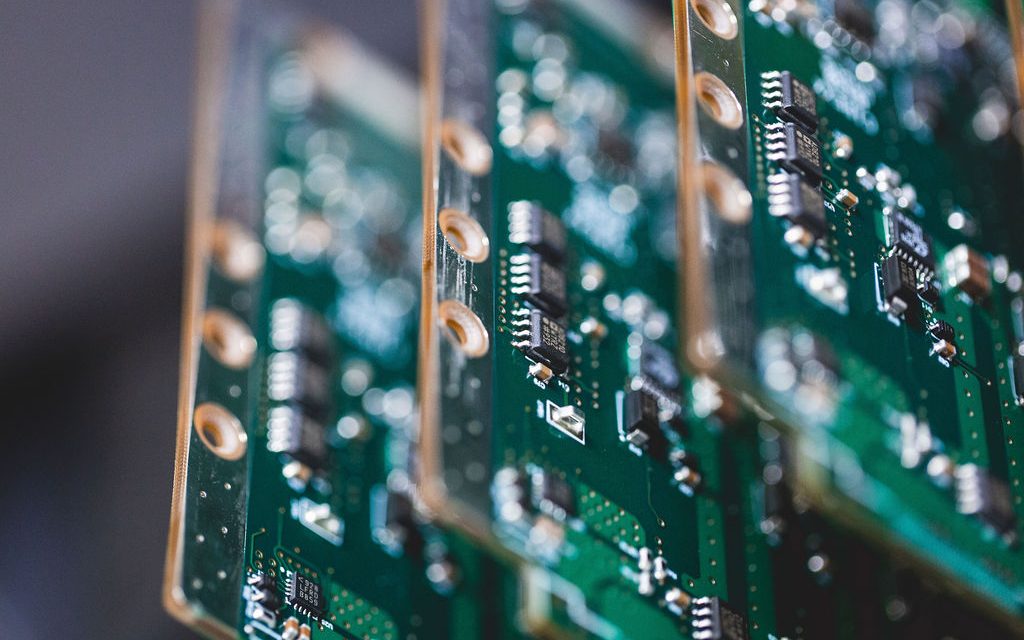

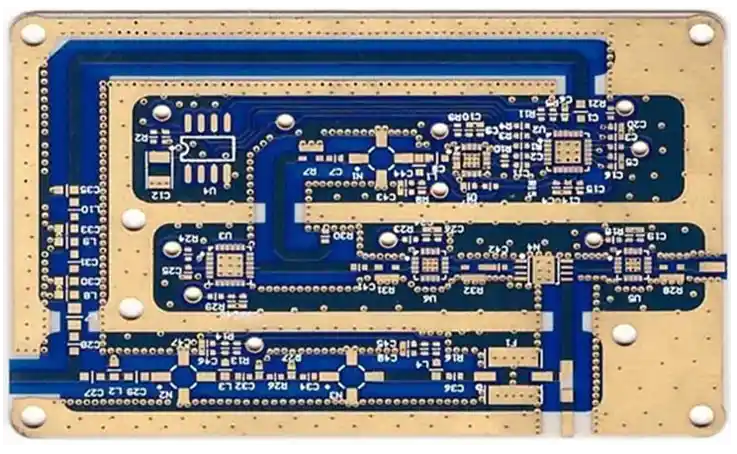

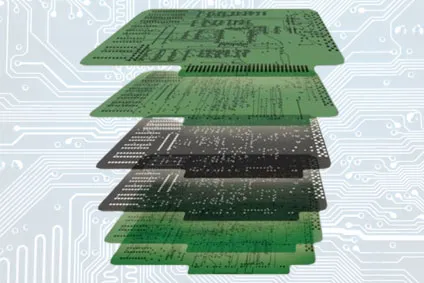

What Is a Multilayer PCB? A multilayer PCB is a printed circuit board composed of multiple copper layers separated by prepreg and core materials. Unlike single-sided or double-sided PCBs, multilayer boards provide additional routing layers, allowing engineers to design high-density circuits with improved electrical performance. Typical multilayer PCB configurations include: 4-layer PCB 6-layer PCB 8-layer...