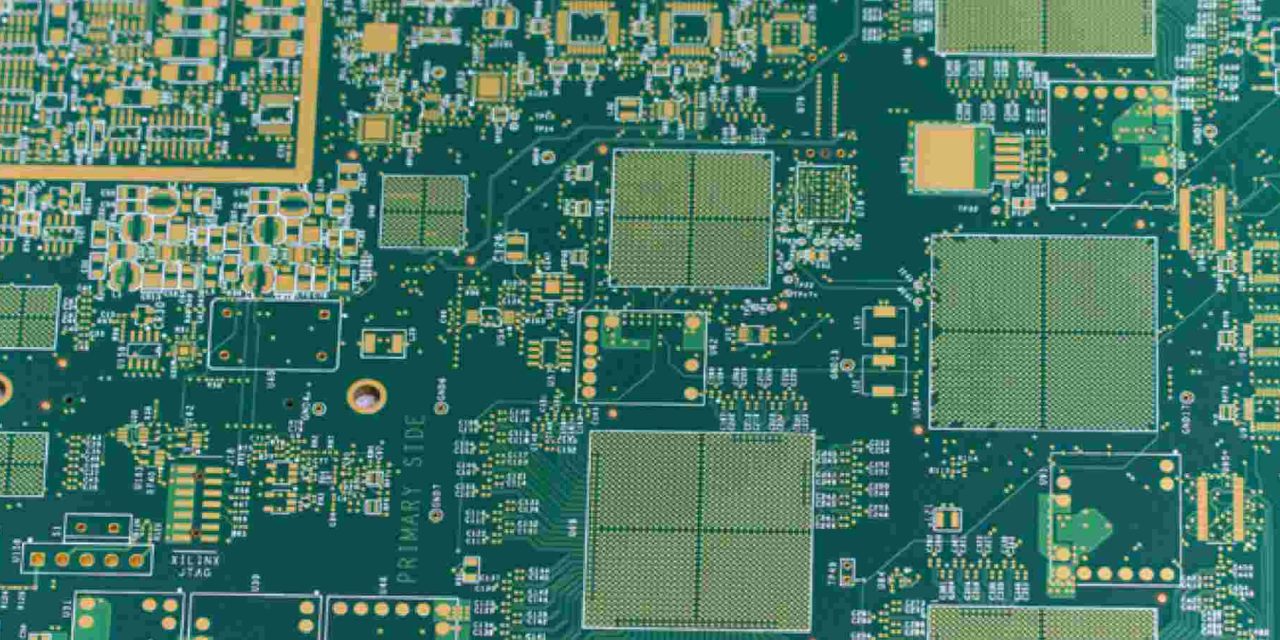

Megtron PCB: A Low-Loss Solution for High-Speed Digital and Advanced Electronics As electronics continue to evolve toward higher data rates, lower latency, and greater integration, PCB materials play a critical role in maintaining signal quality. In high-speed applications such as data centers, servers, 5G infrastructure, and high-performance networking equipment, signal loss and impedance instability can...

HomeTag

Signal Integrity - KKPCB

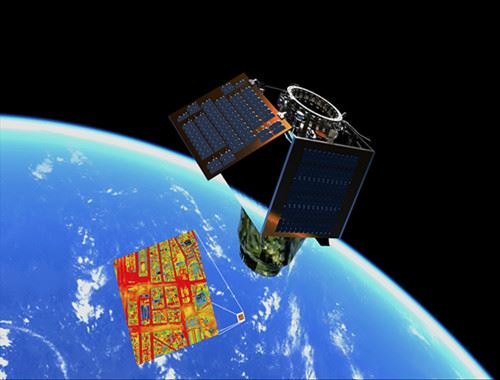

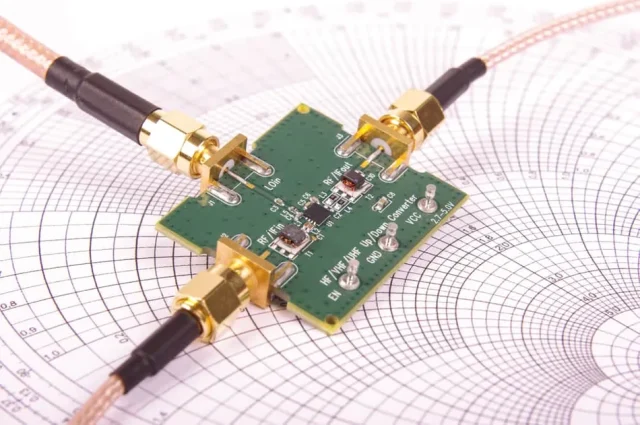

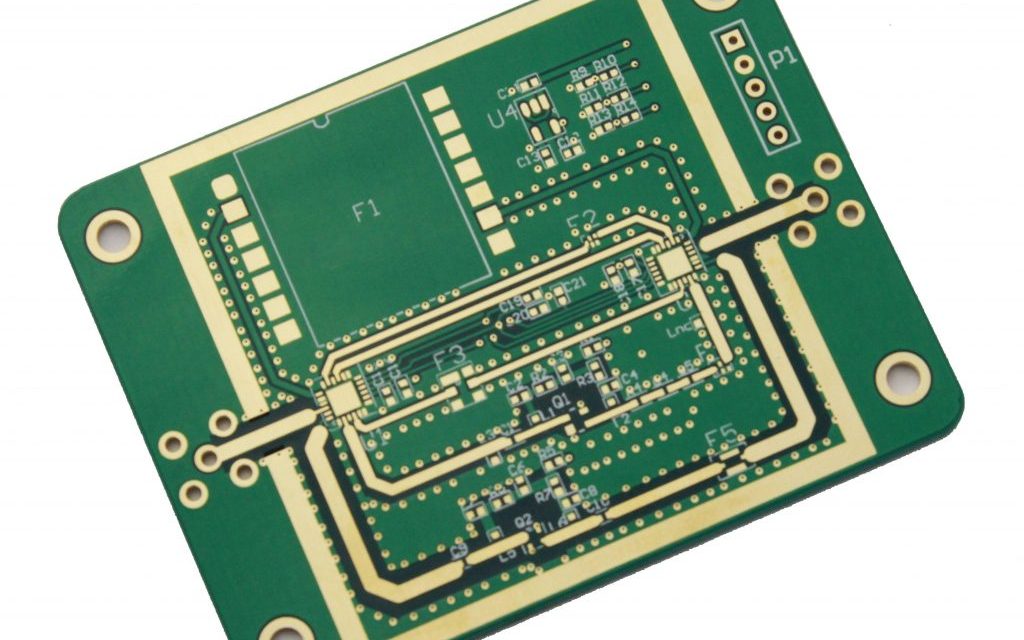

As RF and microwave systems continue to expand in industries such as 5G communications, automotive radar, satellite equipment, and wireless networking, the choice of PCB material becomes critical. At high frequencies, signal integrity and loss performance can no longer rely on standard FR4. RO3003 PCB is a popular solution for high-frequency applications because it provides...

As electronic devices become faster and more complex, maintaining the quality of electrical signals on a PCB is critical. Signal Integrity PCBs are designed to preserve signal quality, minimize noise, and reduce data errors in high-speed circuits. Proper design and manufacturing of these boards are essential for reliable high-performance electronics, from telecommunications and computing to...

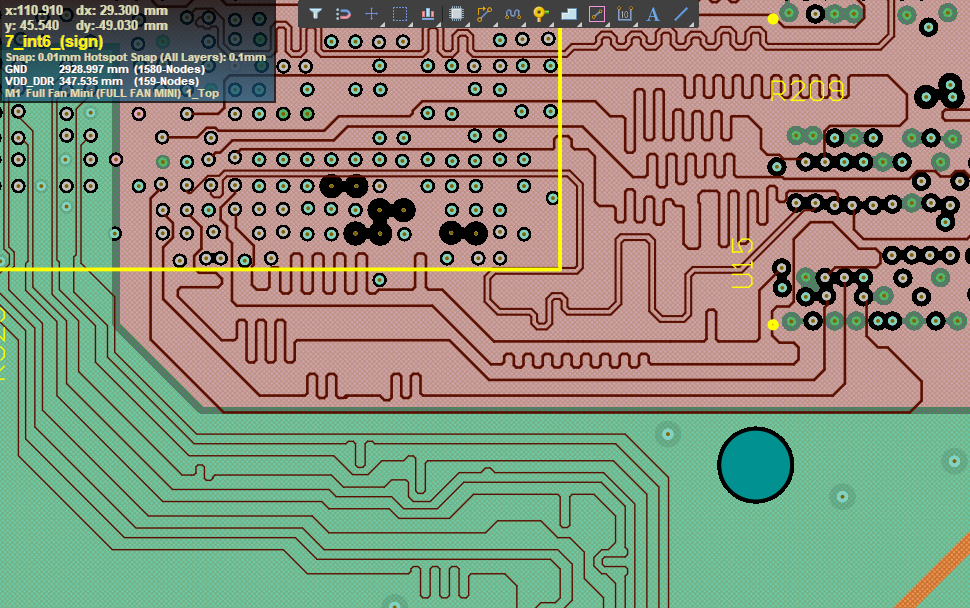

As electronic devices continue to evolve toward higher speeds, greater bandwidth, and higher operating frequencies, impedance control on PCBs has become a critical requirement rather than an optional design consideration. In high-speed PCB, RF PCB, and high-frequency circuit design, improper impedance control can lead to signal degradation, EMI issues, and overall system instability. This article...

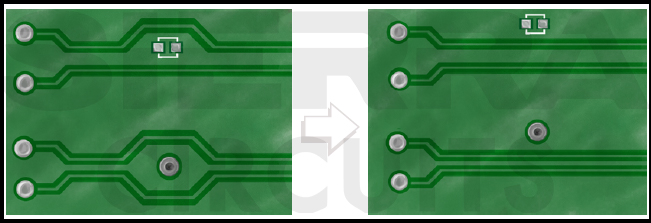

Key Manufacturing Factors That Affect Controlled Impedance PCB Accuracy In today’s high-speed electronics market, Controlled Impedance PCB manufacturing has become a fundamental requirement for ensuring excellent signal integrity and stable electrical performance. As operating frequencies and data transmission speeds continue to rise, even minor impedance deviations in a controlled impedance PCB can result in signal...

Introduction: Why Controlled Impedance Defines High-Speed Reliability As high-speed electronics push into multi-gigabit data rates and high-frequency RF domains, signal behavior is no longer dominated by logic thresholds—it is governed by transmission line physics. In these systems, every PCB trace behaves as a controlled impedance structure, and any deviation can introduce reflections, timing skew, and...

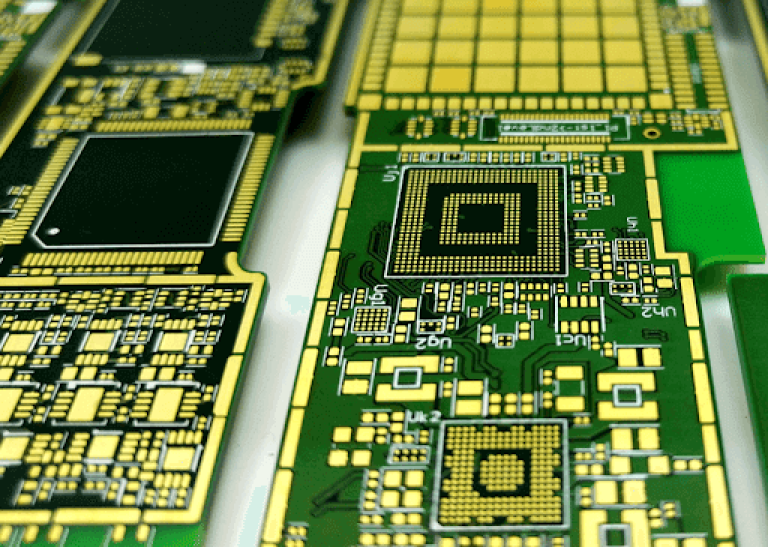

As electronic systems continue to evolve toward higher speeds, greater functionality, and reduced form factors, Buried Via PCB structures have become a critical enabler for advanced multilayer designs. By allowing interlayer connections without penetrating the outer layers, buried vias unlock higher routing density, improved signal integrity, and enhanced EMI control. However, these electrical advantages must...

High-Speed PCB: Engineering Principles, Core Challenges & KKPCB Capabilities High-Speed PCB technology is at the center of every modern data-intensive system—from 5G infrastructure and AI servers to autonomous machines and aerospace communication modules. As signal frequencies climb beyond 3 GHz, 10 GHz, even 28–56 Gbps, traditional PCB design rules become insufficient. High-speed PCB engineering demands...

As digital systems move toward higher data rates, smaller form factors, and lower power consumption, the demand for High Speed PCB solutions continues to accelerate. From 10–112 Gbps SerDes links to DDR4/DDR5 memory buses and advanced communication modules, a High Speed PCB must deliver loss control, impedance stability, and electromagnetic reliability in increasingly complex environments....

A High Speed PCB is no longer a specialty board reserved for telecom giants—it has become the core platform for every high-bandwidth, low-latency, high-frequency electronic architecture. Whether powering 56G/112G SerDes, PCIe 5.0/6.0 interconnects, next-generation routers, AI accelerator hardware, or advanced radar/5G infrastructure, the High Speed PCB defines the system’s ultimate signal integrity, timing accuracy, power...