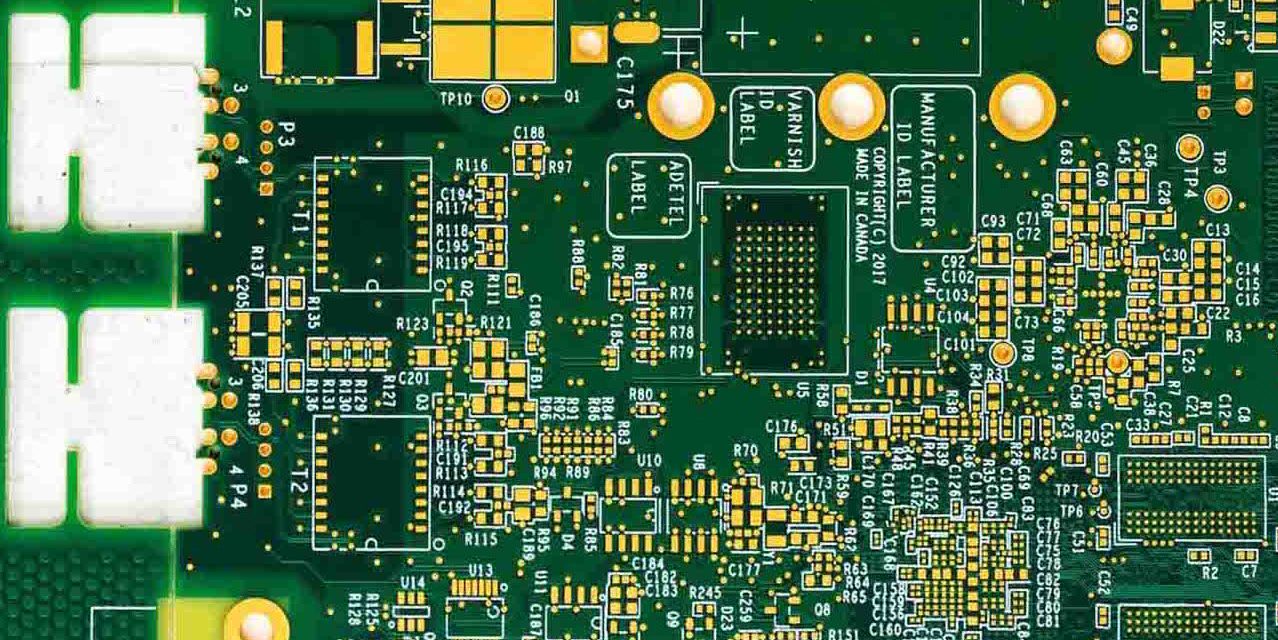

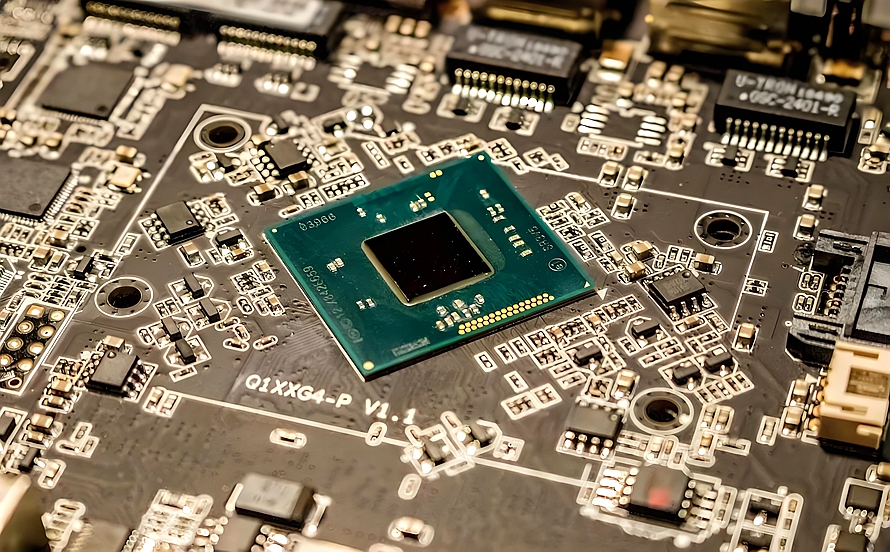

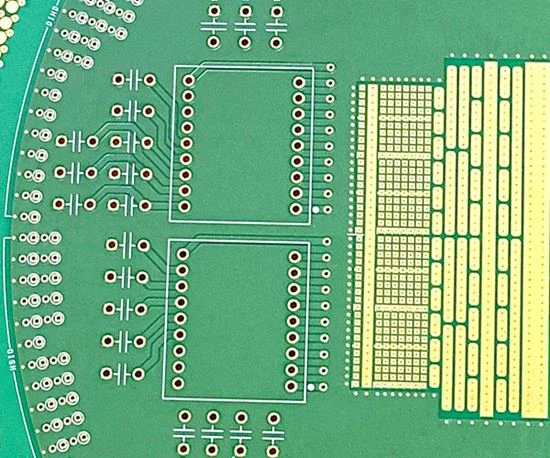

What Is a High Density PCB? A High Density PCB (High Density Printed Circuit Board) is designed to accommodate more components, higher pin counts, and finer routing within a limited board area. It is widely used in applications that require compact size, high performance, and complex signal routing, such as semiconductor testing, telecommunications, automotive electronics,...

HomeTag

semiconductor test PCB - KKPCB

What Is an IoT IC Test PCB? An IoT IC Test PCB is a specialized printed circuit board used to test Internet of Things (IoT) integrated circuits during development, validation, and mass production. It provides a stable electrical interface between the IoT IC under test (DUT) and automated test equipment (ATE), ensuring accurate functional, RF,...

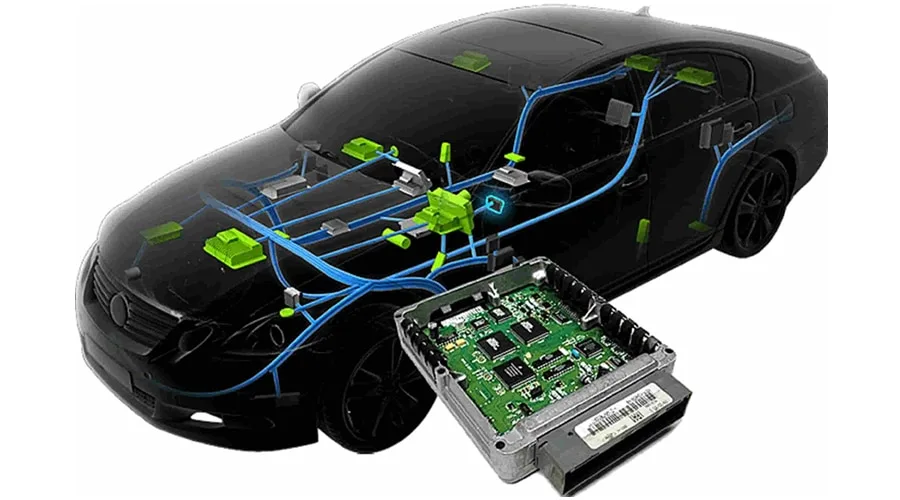

What Is an Automotive IC Test PCB? An Automotive IC Test PCB is a specialized printed circuit board used to test automotive-grade integrated circuits during development, validation, and mass production. It connects the automotive IC under test (DUT) to automated test equipment (ATE), enabling precise electrical, functional, and reliability testing. These PCBs are widely used...

What Is a 5G IC Test PCB? A 5G IC Test PCB is a specialized printed circuit board used to test 5G-related integrated circuits, including RF transceivers, baseband chips, power amplifiers, and mmWave ICs. It serves as the critical interface between the device under test (DUT) and automated test equipment (ATE), ensuring accurate electrical and...

What Is a High Speed IC Test PCB? A High Speed IC Test PCB is a specialized printed circuit board used to test integrated circuits operating at high data rates and high frequencies. It functions as the electrical interface between the device under test (DUT) and automated test equipment (ATE), ensuring accurate transmission and measurement...

As memory devices continue to evolve toward higher speed, higher density, and lower power consumption, precise testing becomes increasingly critical. A well-designed Memory Test PCB is essential for validating the performance, reliability, and functionality of DRAM, NAND Flash, and other memory ICs throughout development and production stages. Memory test PCBs provide the electrical interface between...

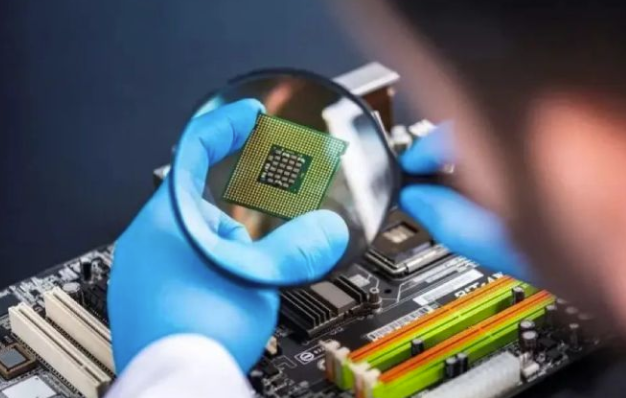

As semiconductor devices become faster, smaller, and more complex, accurate testing at the chip level is essential to ensure product performance and yield. A high-quality Chip Test PCB plays a critical role in IC validation by providing a stable and precise electrical interface between the chip under test and automated test equipment (ATE). Chip test...

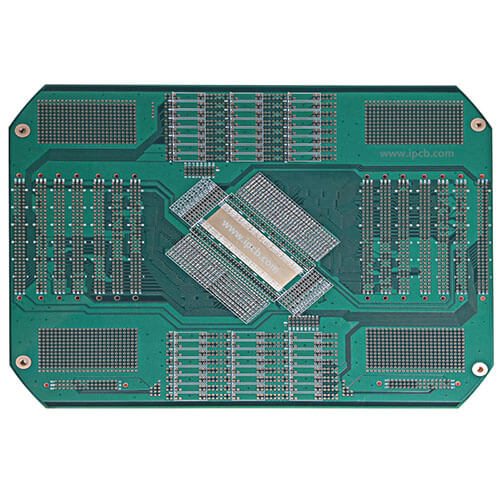

A High Layer Count ATE PCB is a critical component in advanced automated test equipment (ATE) used for semiconductor testing, IC validation, and high-speed functional verification. As modern chips continue to increase in complexity, pin count, and data rate, traditional low-layer PCBs can no longer meet routing density and signal integrity requirements. High layer count...

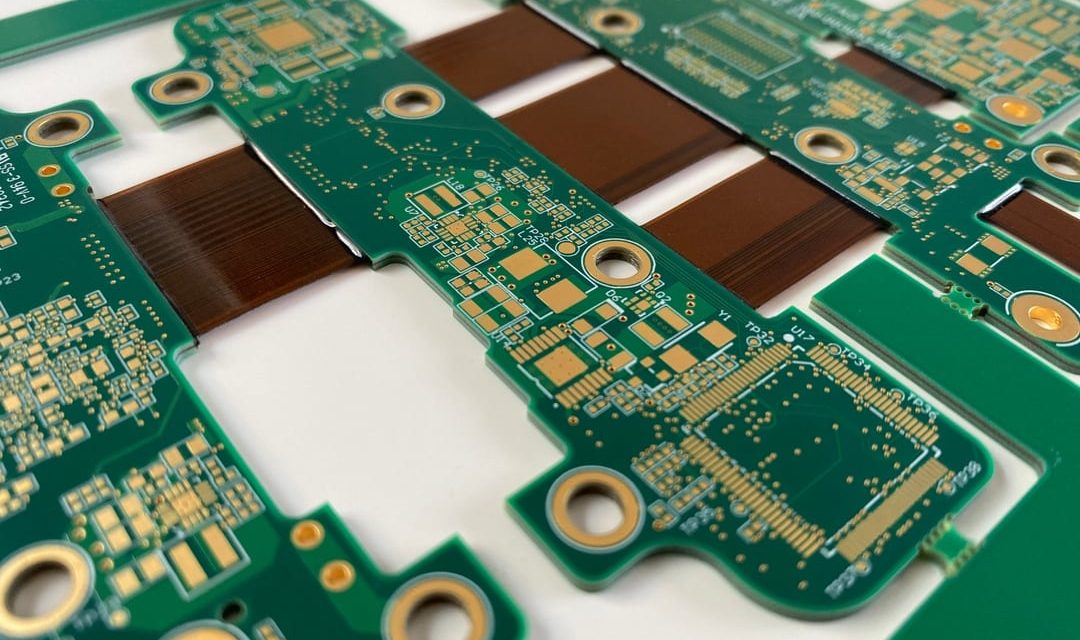

A Rigid-Flex Test PCB combines rigid PCB sections with flexible circuits to create compact, reliable, and high-performance test boards for automated test equipment (ATE) and semiconductor testing systems. As test environments become more complex and space-constrained, rigid-flex test PCBs provide an effective solution by reducing connectors, improving signal integrity, and enhancing mechanical reliability. Rigid-flex test...

Electronics Industry NewsEngineering TechnologiesPCB Assembly (PCBA)PCB DesignPCB ManufacturingPCB Materials

Small Batch ATE PCB Manufacturing for Semiconductor and Automated Test Equipment

Small Batch ATE PCB manufacturing is designed to support semiconductor and automated test equipment (ATE) applications that require low-volume production with high performance and reliability. Unlike mass production PCBs, small batch ATE PCBs are typically used for engineering validation, system qualification, pilot runs, and customized test solutions. As test requirements continue to evolve rapidly, small...