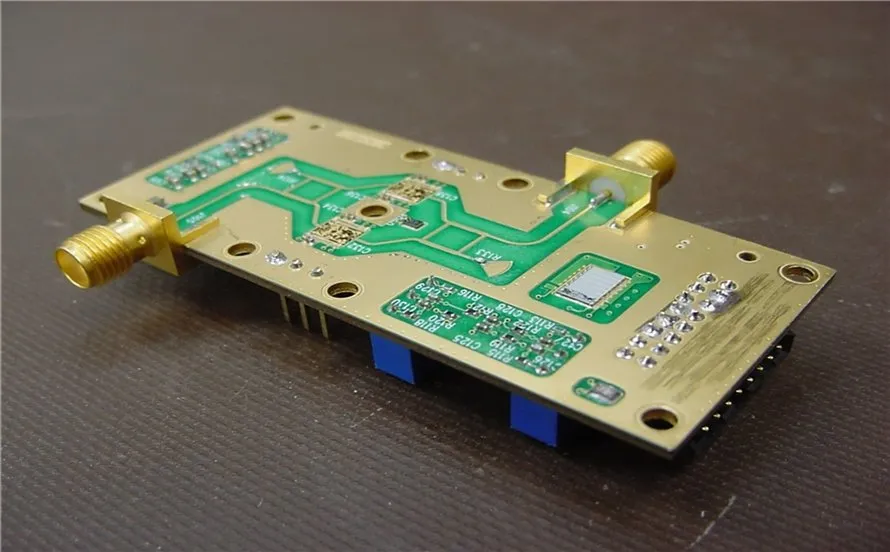

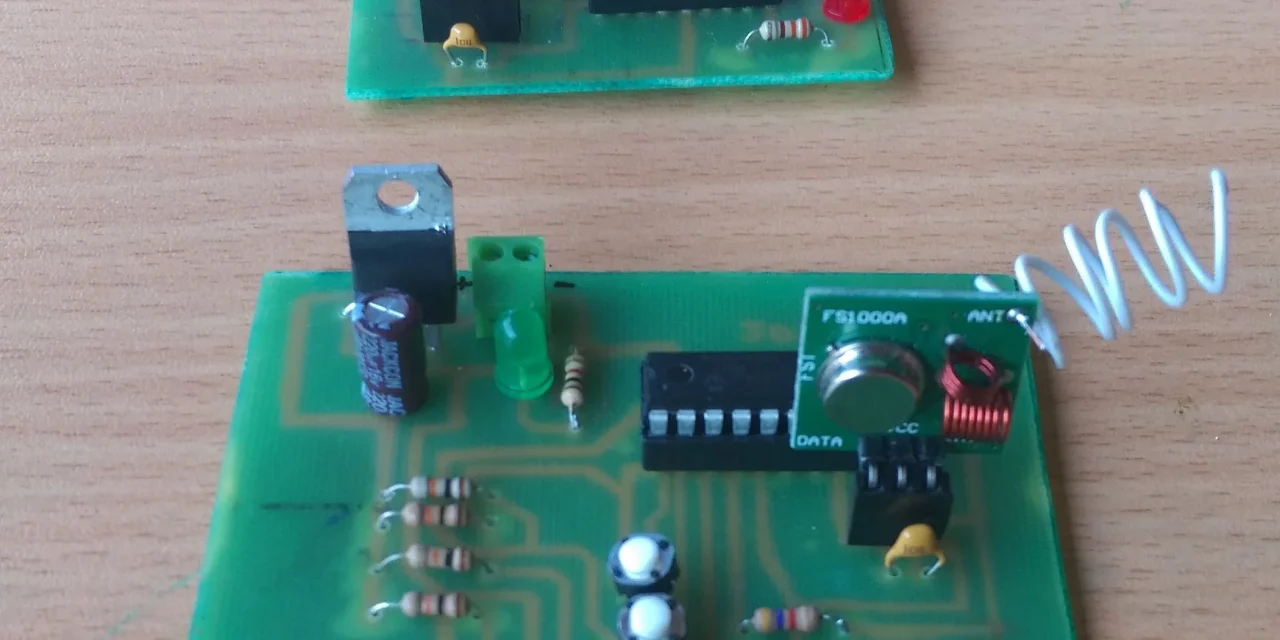

What Is an RF Transceiver PCB? An RF Transceiver PCB is a specialized printed circuit board used in radio frequency transmission and reception systems. It integrates RF transmit (TX) and receive (RX) circuits on the same board, requiring precise control of signal integrity, impedance, and electromagnetic performance. RF transceiver PCBs are critical in modern wireless...

HomeTag

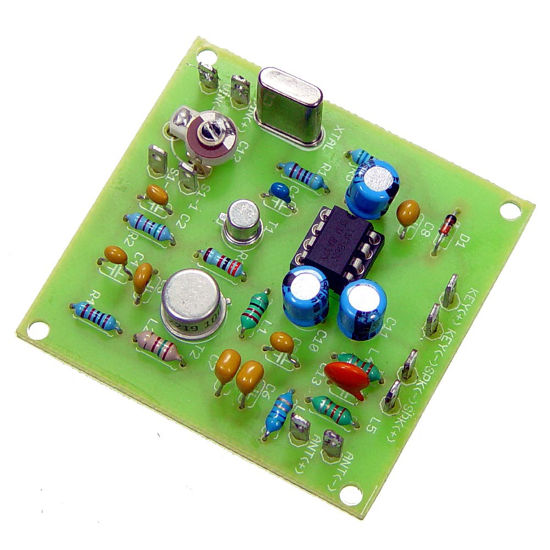

RF Module PCB - KKPCB

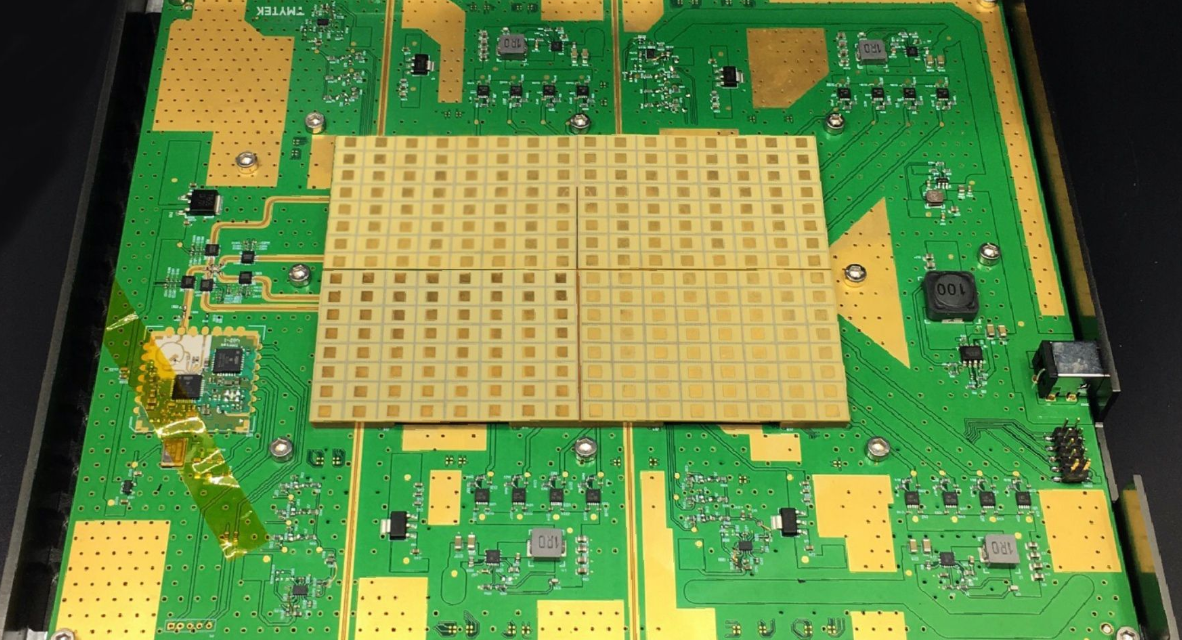

What Is a mmWave Module PCB? A mmWave Module PCB is a specialized printed circuit board designed to operate at millimeter-wave frequencies (typically 24 GHz to 110 GHz). These PCBs are used in compact RF modules where signal loss, impedance variation, and electromagnetic interference must be tightly controlled. mmWave module PCBs are core components in...

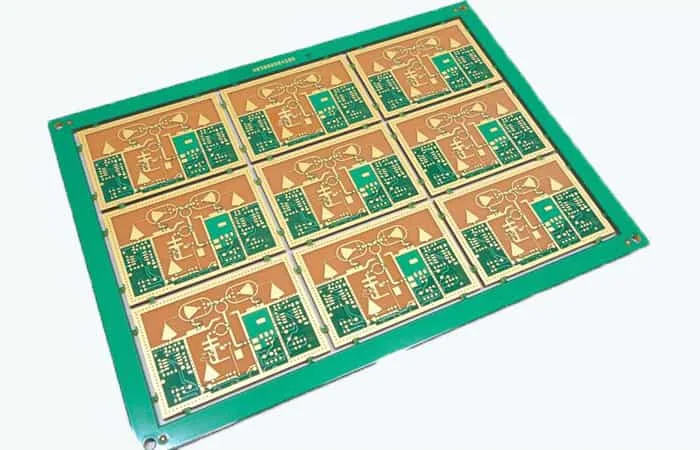

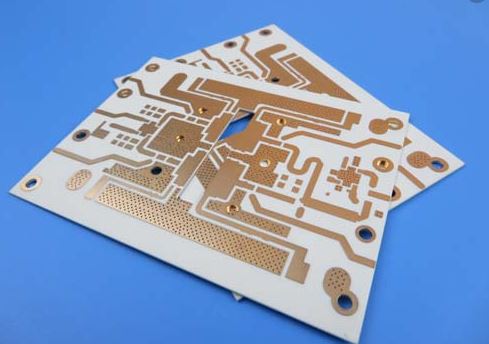

What Is a Rogers PCB? A Rogers PCB is a high-frequency printed circuit board manufactured using Rogers laminate materials, which are engineered for RF, microwave, and high-speed signal applications. Compared with standard FR-4, Rogers materials offer lower dielectric loss, more stable dielectric constant (Dk), and better electrical performance at high frequencies. Because of these advantages,...

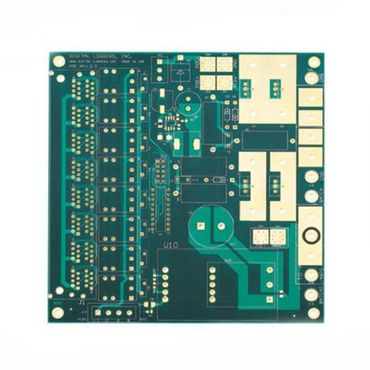

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to transmit high-frequency electrical signals—typically in the MHz to GHz range—while maintaining signal integrity, minimizing loss, and reducing EMI. These PCBs are critical in applications such as RF communication, microwave devices, 5G modules, radar systems, high-speed networking,...

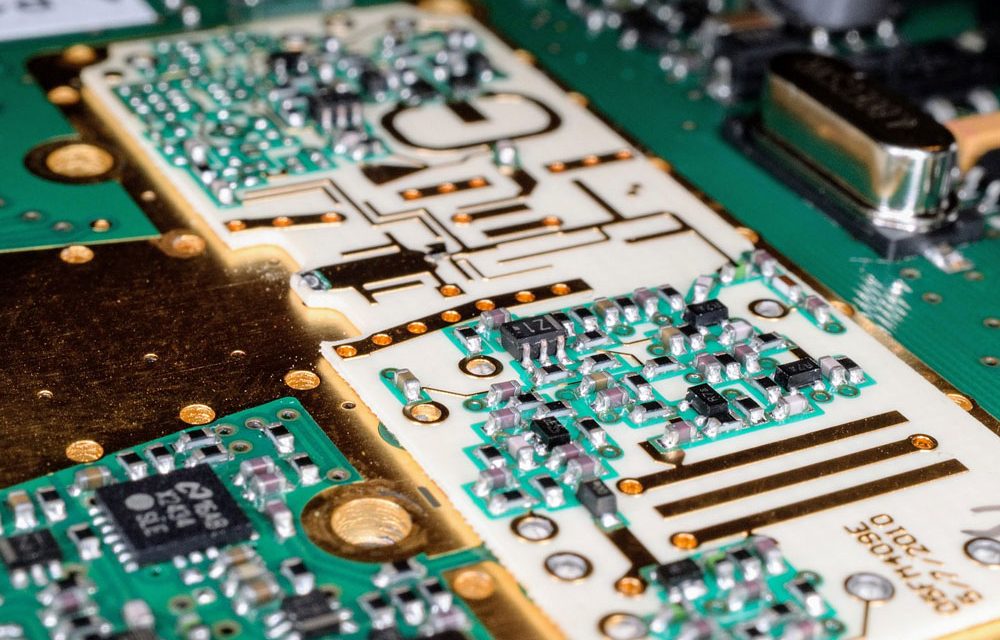

What Is an RF Trace PCB? An RF Trace PCB is a printed circuit board designed with optimized RF trace routing to carry radio frequency (RF) signals with minimal loss, stable impedance, and strong EMI control. RF traces are transmission lines that must maintain consistent electrical performance at high frequencies, typically from hundreds of MHz...

What Is an RO4003C PCB? An RO4003C PCB is a high-frequency printed circuit board manufactured using Rogers RO4003C laminate, specifically designed for RF, microwave, and high-speed digital applications. RO4003C combines low dielectric loss, tight dielectric constant control, and good thermal stability, making it a popular and cost-effective alternative to PTFE-based materials. RO4003C PCBs are widely...

As 5G RF front-end modules push into sub-6 GHz and mmWave bands, PCB materials must deliver extreme electrical precision, low-loss propagation, and predictable thermal behavior. TLY-5 PCB laminates, based on PTFE composites engineered with ultra-low dielectric constant (Dk ≈ 2.17) and low dissipation factor (Df ≈ 0.0009), have emerged as one of the most reliable...

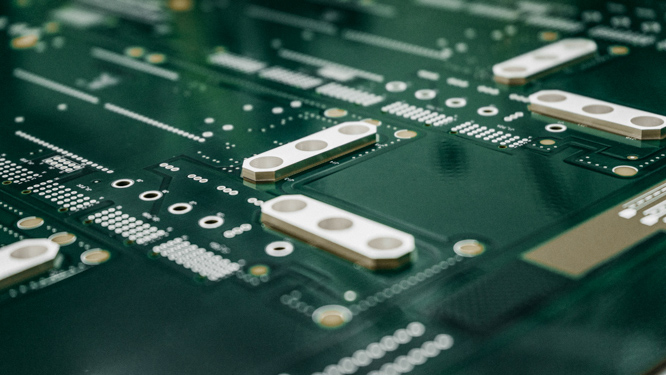

1. Engineering Context Next-generation mmWave communication systems—including 5G base stations, satellite payloads, and radar modules—require PCBs that provide ultra-stable impedance, low insertion loss, and phase-consistent routing. Traditional FR-4 or high-speed laminates often suffer from dielectric drift, higher Df, and thermal expansion issues, which degrade signal fidelity, EMI immunity, and system reliability in dense multi-layer RF...

High-frequency communication systems—from 5G NR radios and phased-array front ends to satellite downlink modules and wideband radar—rely on precisely engineered RF Transceiver PCB architectures to maintain low-loss signal chains, stable phase performance, and strong EMI suppression. As operating frequencies rise into sub-6 GHz, C-band, Ku-band, Ka-band and even mmWave ranges, the electrical behavior of the...

Modern wireless systems—from satellite communication payloads to 5G/6G infrastructure and defense-grade radar—depend on the precision, stability, and reliability of RF Transceiver PCB architectures. As operating frequencies rise into the sub-6 GHz, Ku-, Ka-, and mmWave bands, the RF Transceiver PCB becomes the defining foundation for signal integrity, phase coherence, and power efficiency. High-frequency electronics demand...