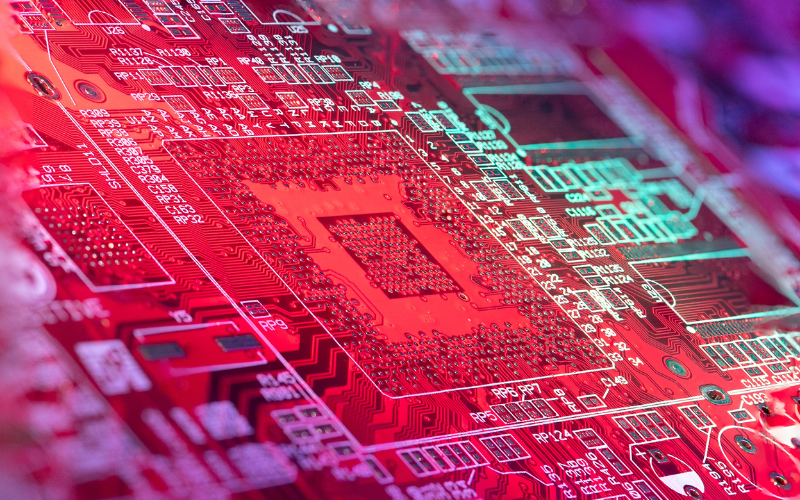

What Is a High Current PCB? A High Current PCB is a printed circuit board specifically designed to carry large currents while maintaining electrical stability and thermal reliability. These PCBs are commonly used in power electronics, automotive inverters, industrial automation, renewable energy systems, and high-current semiconductor testing. High current PCBs typically feature thick copper layers,...

HomeTag

Power Electronics PCB - KKPCB

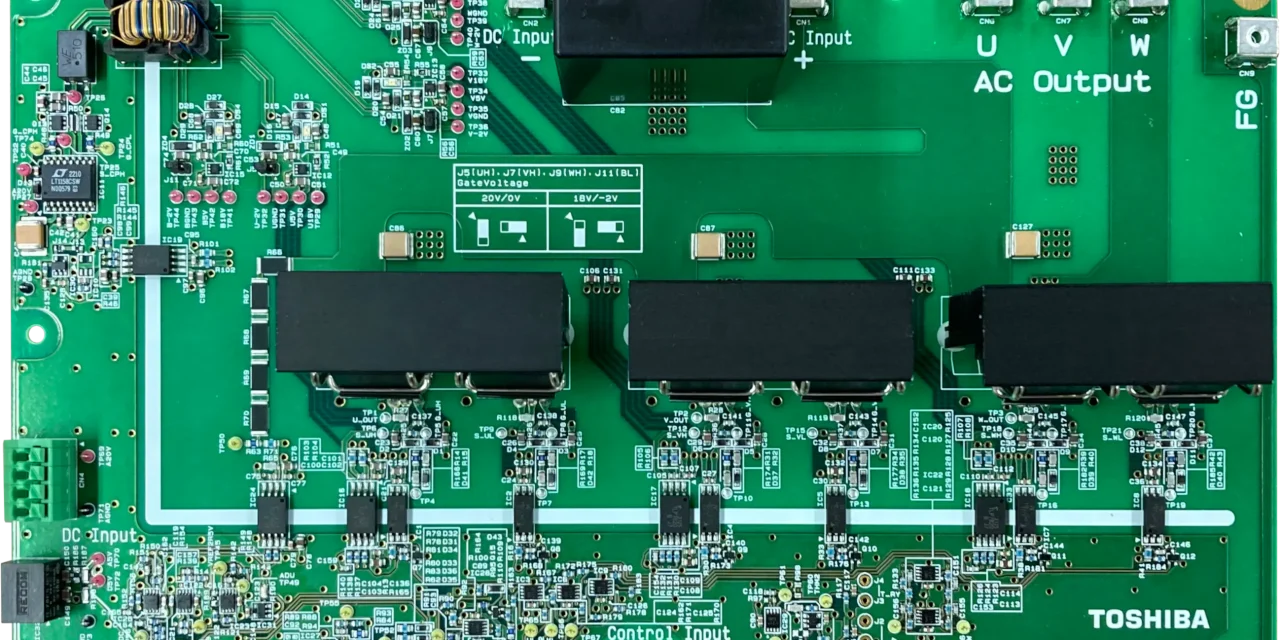

What Is a SiC PCB? A SiC PCB is a specialized printed circuit board designed for silicon carbide (SiC) power devices, such as SiC MOSFETs and SiC diodes. These PCBs are engineered to operate under high voltage, high current, and high temperature conditions commonly found in advanced power electronics. Compared with conventional PCBs, SiC PCBs...

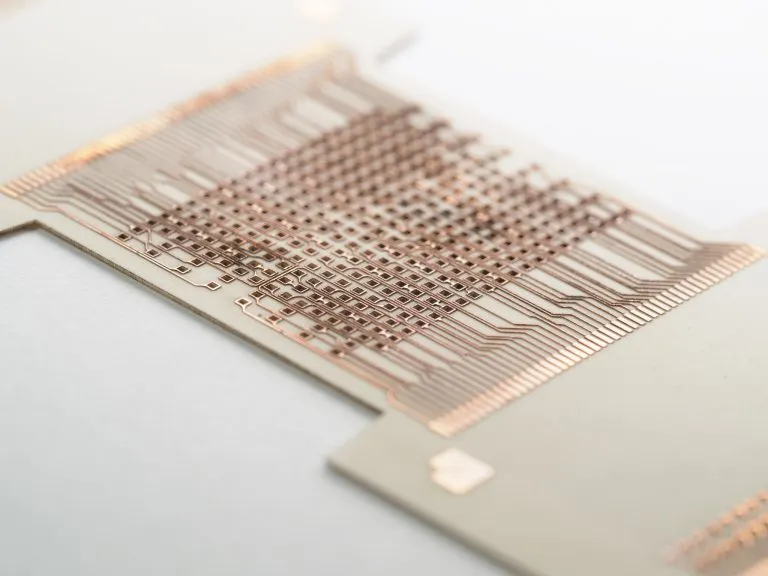

What Is an Alumina PCB? An Alumina PCB is a type of ceramic PCB manufactured using aluminum oxide (Al₂O₃) as the base substrate. Unlike traditional FR-4 materials, Alumina PCB provides superior thermal conductivity, excellent electrical insulation, and outstanding stability under high temperature and high power conditions. Because of these characteristics, Alumina PCBs are widely used...

What Is an Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Compared with organic laminates, Alumina PCBs provide superior thermal conductivity, excellent electrical insulation, and outstanding resistance to high temperature and harsh environments. Alumina PCBs are widely used in power electronics, semiconductor packaging,...

What Is Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Alumina ceramic PCBs are widely used in high-power, high-temperature, and high-reliability electronic applications due to their excellent thermal conductivity, electrical insulation, and mechanical strength. Compared with traditional FR-4 PCBs, Alumina PCBs provide superior...

Hybrid PCB materials are engineered by combining multiple laminate systems within a single PCB stackup to meet diverse electrical, thermal, and mechanical requirements. As electronic systems increasingly integrate high-speed digital, RF, and power circuitry on one board, no single material can simultaneously optimize all performance parameters. Hybrid PCB materials provide a practical engineering solution to...

High TG materials play a decisive role in modern PCB designs where elevated operating temperatures, complex multilayer stackups, and long-term reliability are mandatory. As electronic systems continue to push higher power density and tighter integration, conventional low-TG laminates increasingly become a limiting factor in both manufacturing yield and field performance. Understanding the Importance of TG...

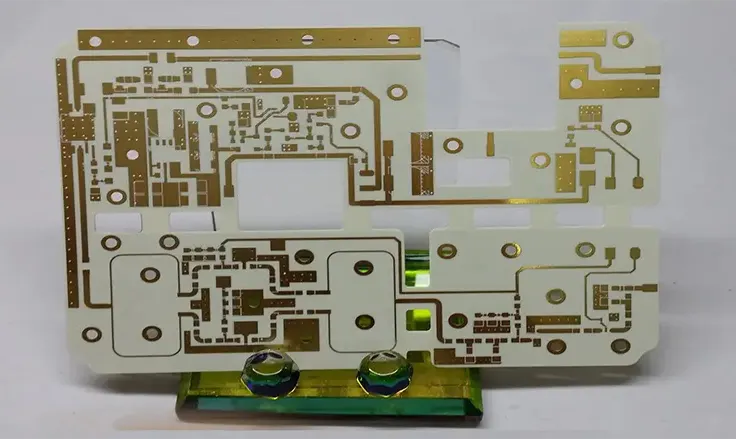

Aluminum Nitride PCB (AlN PCB) is a ceramic substrate technology specifically engineered for electronic systems where power density, thermal stress, and operating temperature exceed the limits of conventional PCB materials. In high-power and high-temperature environments, Aluminum Nitride PCBs serve not only as circuit carriers but as primary thermal management and reliability enablers. Why Aluminum Nitride...

A Ceramic PCB is a substrate technology selected when thermal limits, electrical insulation, and mechanical stability become primary system constraints. In high-power and high-voltage electronic systems, ceramic substrates are not simply alternatives to organic laminates—they function as integrated thermal and structural elements within the overall design architecture. Ceramic PCB as a Thermal Path Element In...

Hybrid PCB materials are engineered substrates that combine multiple material types to achieve optimized electrical, thermal, and mechanical performance in demanding electronic applications. By integrating properties of FR-4, high-frequency laminates, PTFE, or ceramic materials, hybrid PCBs enable designers to meet multi-domain requirements that a single material cannot satisfy. Material Characteristics of Hybrid PCB Materials The...