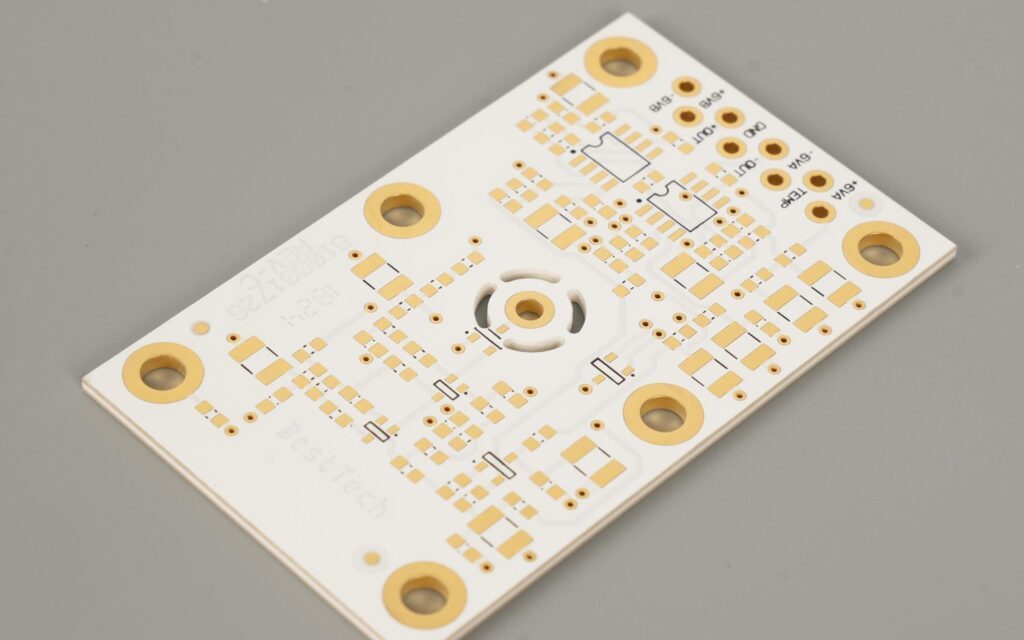

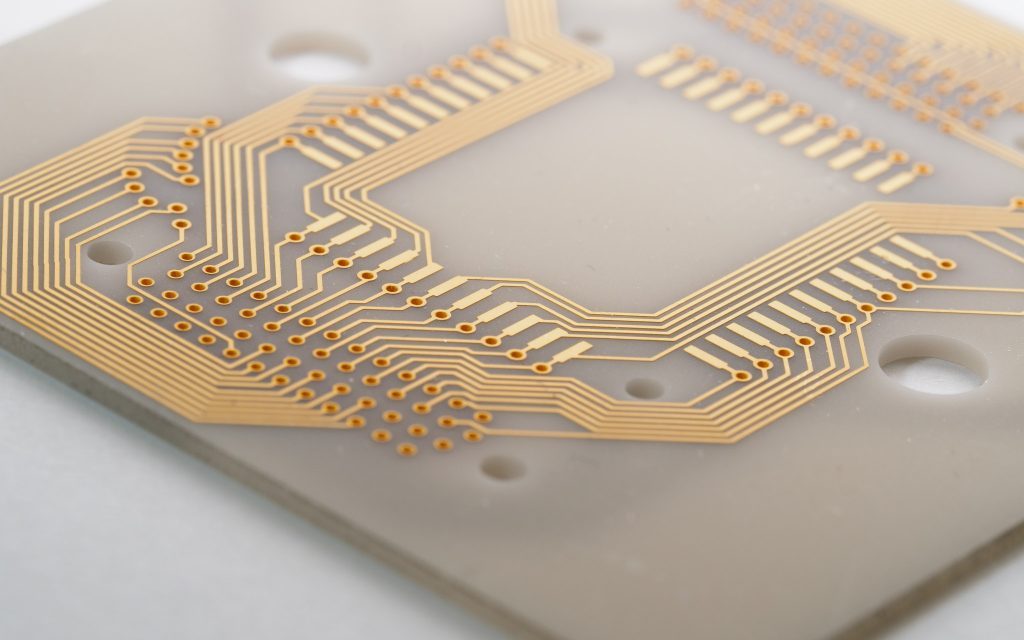

What Is an Aluminum Nitride PCB? An Aluminum Nitride PCB (AlN PCB) is a high-performance ceramic printed circuit board manufactured using Aluminum Nitride substrate material, known for its exceptionally high thermal conductivity and excellent electrical insulation properties. Compared to traditional FR-4 or even Alumina ceramic PCBs, Aluminum Nitride PCB offers significantly enhanced heat dissipation performance,...

HomeTag

High Thermal Conductivity PCB - KKPCB

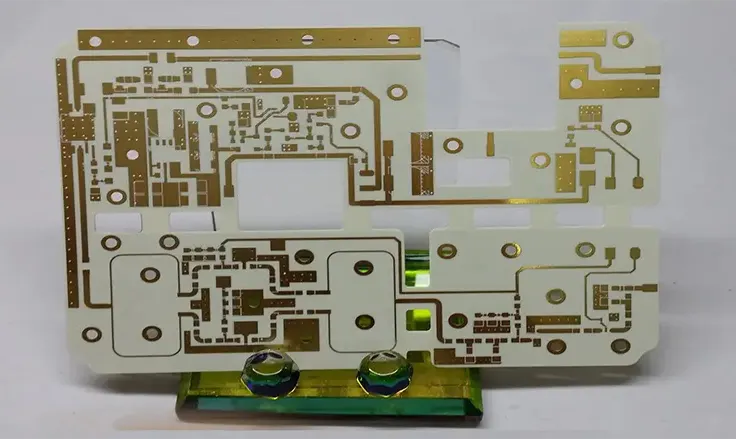

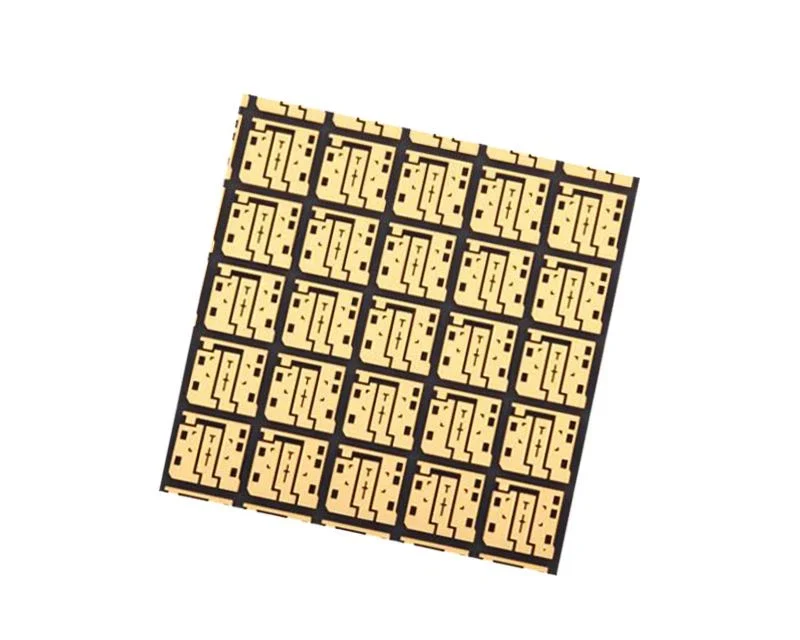

What Is an Alumina PCB? An Alumina PCB is a type of ceramic PCB manufactured using aluminum oxide (Al₂O₃) as the base substrate. Unlike traditional FR-4 materials, Alumina PCB provides superior thermal conductivity, excellent electrical insulation, and outstanding stability under high temperature and high power conditions. Because of these characteristics, Alumina PCBs are widely used...

What Is an Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Compared with organic laminates, Alumina PCBs provide superior thermal conductivity, excellent electrical insulation, and outstanding resistance to high temperature and harsh environments. Alumina PCBs are widely used in power electronics, semiconductor packaging,...

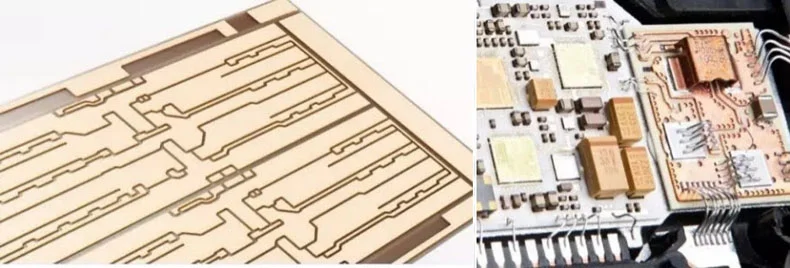

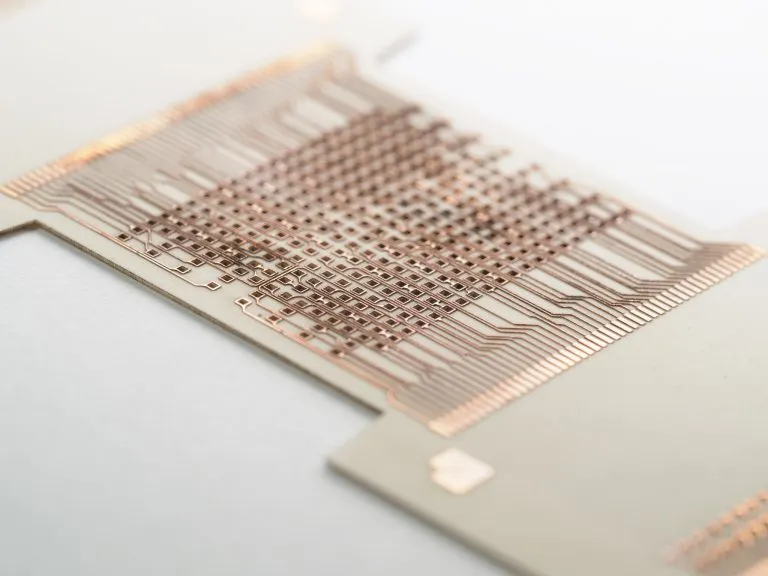

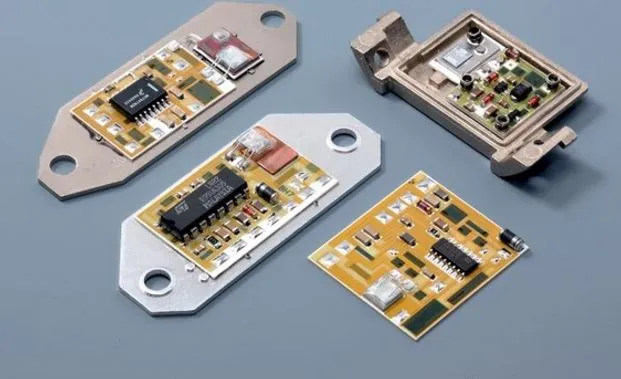

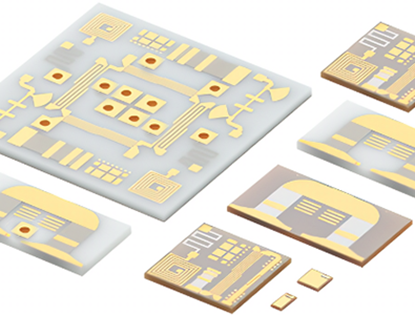

A Ceramic PCB is a substrate technology selected when thermal limits, electrical insulation, and mechanical stability become primary system constraints. In high-power and high-voltage electronic systems, ceramic substrates are not simply alternatives to organic laminates—they function as integrated thermal and structural elements within the overall design architecture. Ceramic PCB as a Thermal Path Element In...

An Aluminum Nitride PCB (AlN PCB) is a ceramic-based circuit substrate engineered for electronic systems that demand exceptional thermal conductivity, electrical insulation, and dimensional stability under high power density and elevated temperature conditions. In power electronics and high-reliability applications, material selection is not a secondary decision—it defines system performance limits. Material-driven Aluminum Nitride PCB design...

A Ceramic PCB is a high-performance circuit substrate engineered for applications that demand excellent thermal conductivity, electrical insulation, and long-term reliability under harsh operating conditions. Unlike organic PCB materials such as FR-4 or PTFE, ceramic PCB substrates are inorganic, enabling stable electrical and mechanical performance at elevated temperatures and high power densities. Ceramic PCB technology...

Aluminum Nitride PCB: The Premium Ceramic Substrate for Advanced Thermal Management As modern electronics continue to push toward higher power density, smaller size, and higher reliability, thermal management becomes a key design challenge. In applications such as power modules, EV systems, high-brightness LEDs, and industrial converters, standard PCB materials often struggle to dissipate heat effectively....

Ceramic PCB: The Ideal Solution for Heat Dissipation and High-Reliability Electronics As electronic products become smaller, more powerful, and more integrated, thermal management has become one of the biggest challenges in modern PCB design. In applications such as power modules, high-brightness LEDs, automotive electronics, and industrial control systems, standard FR4 boards may struggle with heat...

As modern electronics continue to evolve toward higher power density, smaller packaging, and harsher operating environments, thermal performance has become one of the most important factors in PCB material selection. In applications such as EV power modules, IGBT and MOSFET power stages, SiC/GaN devices, and high brightness LED modules, traditional FR-4 PCBs often cannot provide...

As modern electronics move toward higher power density, smaller form factors, and more demanding operating environments, thermal performance has become one of the most critical design factors. In applications such as power modules, LED lighting, automotive electronics, industrial power control, and advanced SiC/GaN power devices, conventional FR-4 PCBs may struggle with heat dissipation, long-term reliability,...