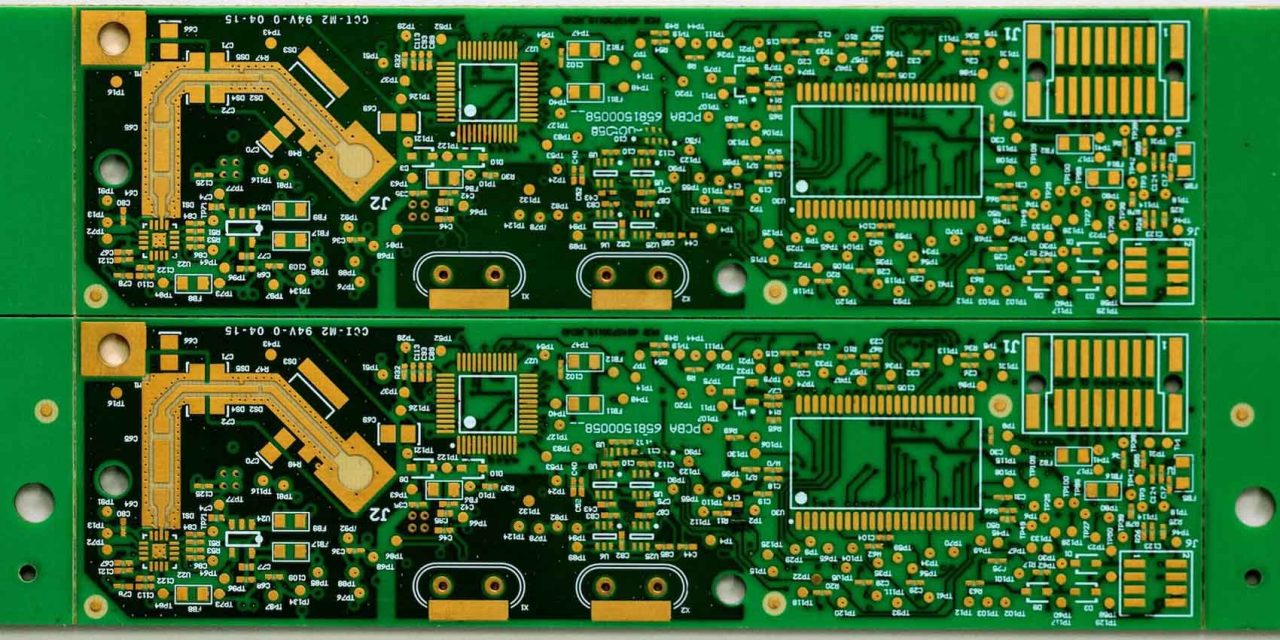

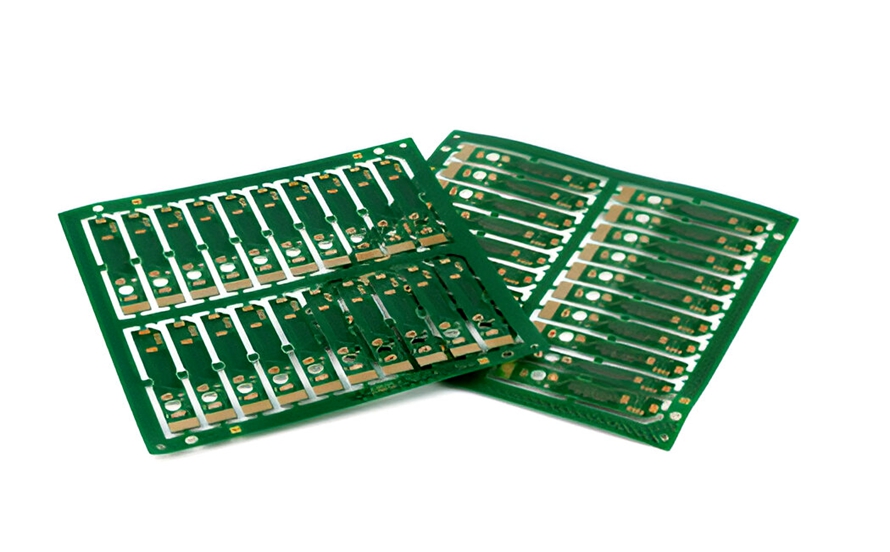

What Is a Burn-in PCB? A Burn-in PCB is a specialized printed circuit board designed for semiconductor burn-in testing. It is used to apply electrical and thermal stress to integrated circuits (ICs) over an extended period to identify early-life failures and ensure long-term reliability. Burn-in testing is a critical quality control process in semiconductor manufacturing,...

HomeTag

high-Tg PCB - KKPCB

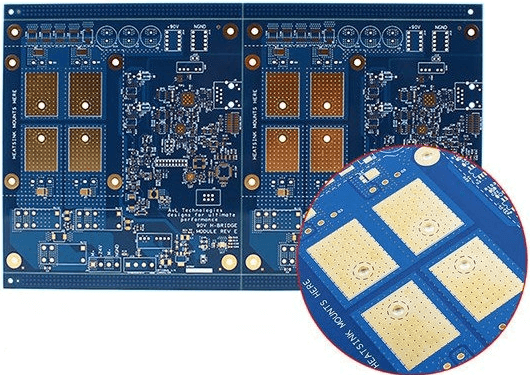

What Are Hybrid PCB Materials? Hybrid PCB materials refer to multilayer PCB constructions that combine two or more different laminate materials within the same stack-up. Instead of using a single material throughout the board, hybrid PCB designs integrate materials such as: Standard FR-4 High TG materials Low loss laminates High frequency laminates (Rogers, PTFE, etc.)...

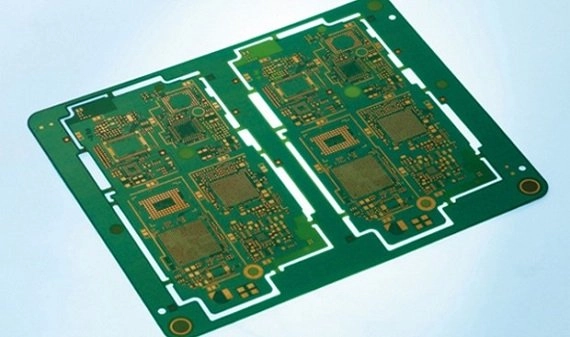

What Are High TG Materials? High TG materials refer to PCB laminate materials with a high glass transition temperature (Tg), typically above 170°C and often reaching 180°C–200°C or higher. The Tg value indicates the temperature at which the PCB material transitions from a rigid glass-like state to a softer rubber-like state. Using high TG materials...

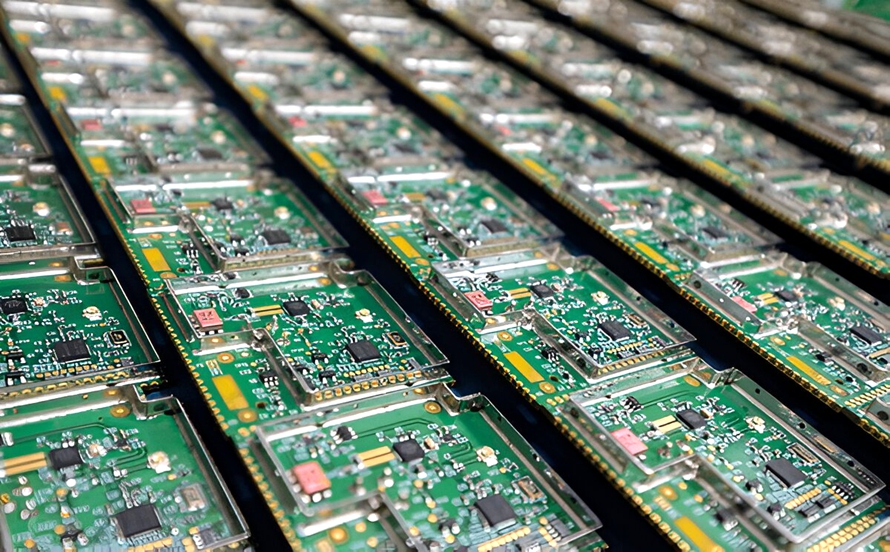

What Is a BT Epoxy PCB? A BT Epoxy PCB is a high-performance printed circuit board manufactured using Bismaleimide Triazine (BT) resin-based epoxy material. BT Epoxy PCB is widely used in IC substrate applications, semiconductor packaging, memory modules, and high-density electronic devices, where thermal stability, dimensional accuracy, and electrical performance are critical. Compared with standard...

What Is a High Reliability PCB? A High Reliability PCB is a printed circuit board designed and manufactured to perform consistently under extreme environmental, electrical, and mechanical conditions. These PCBs are engineered for long service life, stable electrical performance, and minimal failure risk. High reliability PCBs are essential for applications where system failure is not...

What Is a High TG PCB? A High TG PCB is a printed circuit board manufactured using materials with a high glass transition temperature (Tg). The Tg value indicates the temperature at which the PCB substrate transitions from a rigid state to a softer, rubber-like state. Compared to standard FR-4, High Tg PCBs maintain mechanical...

A Burn-in PCB is a specialized test interface designed for accelerated semiconductor reliability screening under sustained electrical and thermal stress. In burn-in systems, the PCB is exposed to continuous high temperature, elevated voltage, and long operating cycles, making it one of the most mechanically and electrically stressed PCB types in semiconductor test environments. Unlike functional...

Hybrid PCB materials are engineered by combining multiple laminate systems within a single PCB stackup to meet diverse electrical, thermal, and mechanical requirements. As electronic systems increasingly integrate high-speed digital, RF, and power circuitry on one board, no single material can simultaneously optimize all performance parameters. Hybrid PCB materials provide a practical engineering solution to...

High TG materials play a decisive role in modern PCB designs where elevated operating temperatures, complex multilayer stackups, and long-term reliability are mandatory. As electronic systems continue to push higher power density and tighter integration, conventional low-TG laminates increasingly become a limiting factor in both manufacturing yield and field performance. Understanding the Importance of TG...

Hybrid PCB materials combine two or more substrate types—such as high-speed laminates, low-loss materials, BT epoxy, and ceramics—to create boards optimized for electrical performance, thermal management, and mechanical stability. Unlike single-material PCBs, hybrid designs allow engineers to tailor material properties to different areas of the circuit, achieving performance levels unattainable with conventional laminates. Why Hybrid...