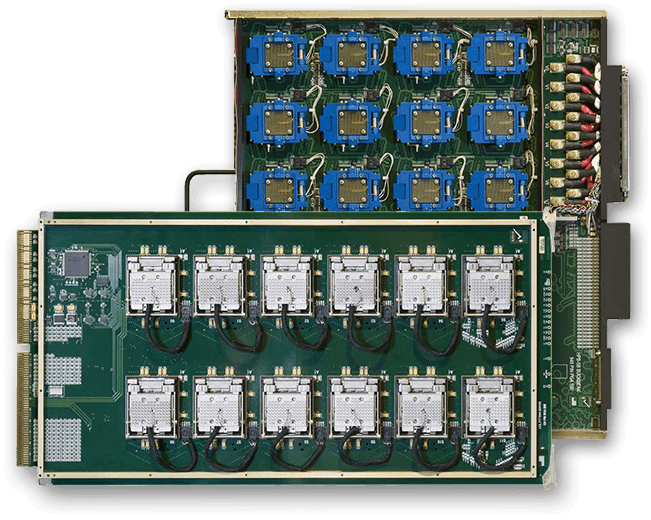

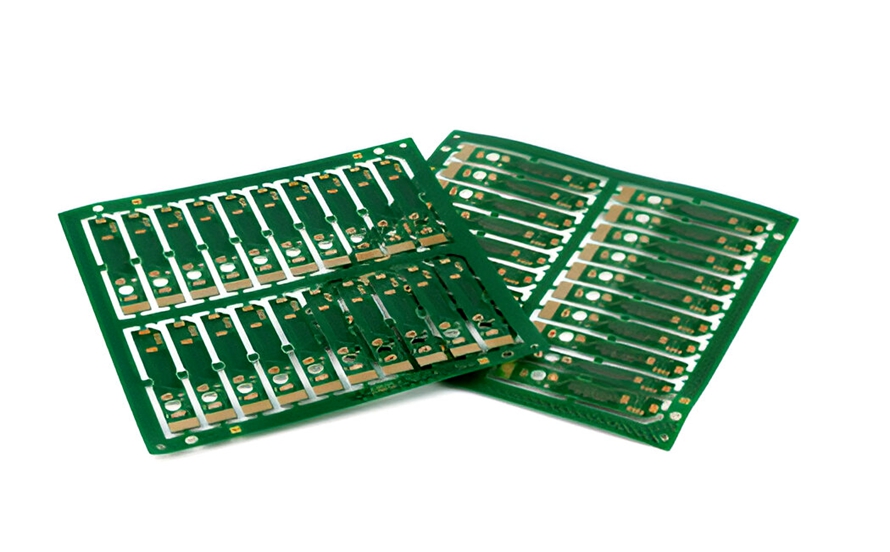

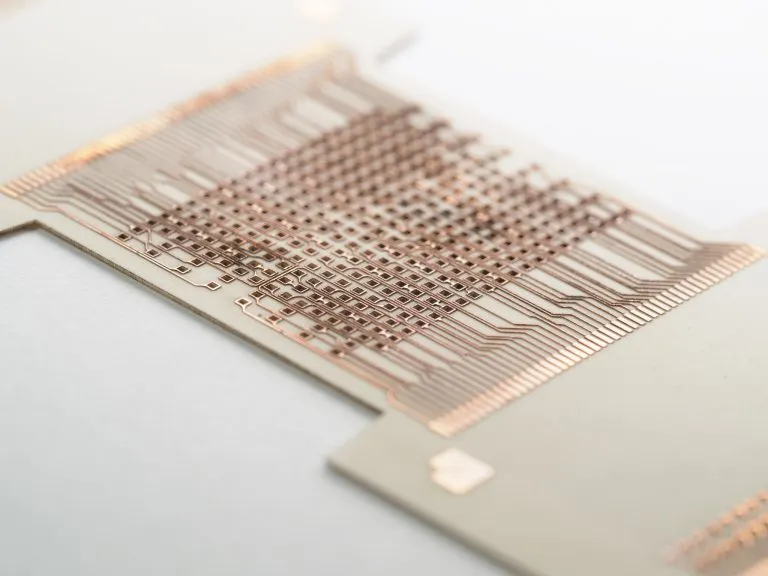

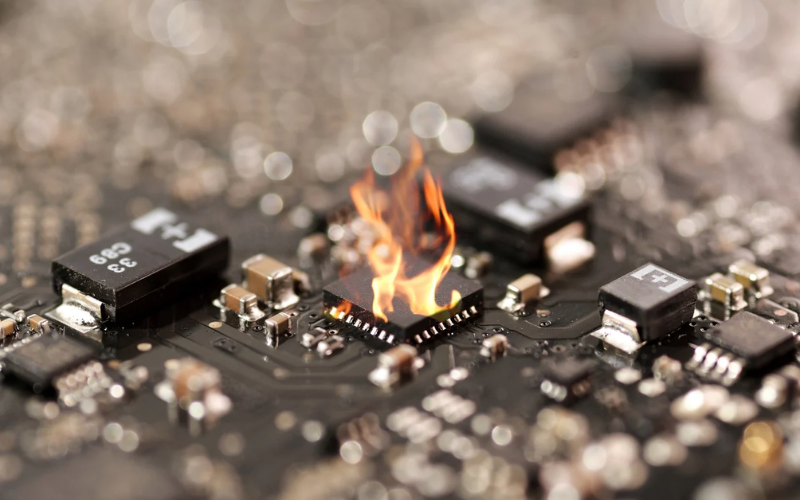

What Is a Burn-in PCB? A Burn-in PCB is a specialized printed circuit board designed for semiconductor burn-in testing. It is used to apply electrical and thermal stress to integrated circuits (ICs) over an extended period to identify early-life failures and ensure long-term reliability. Burn-in testing is a critical quality control process in semiconductor manufacturing,...

HomeTag

High Temperature PCB - KKPCB

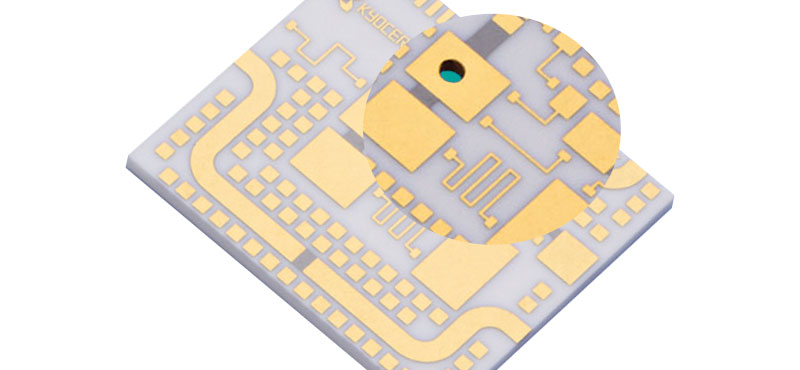

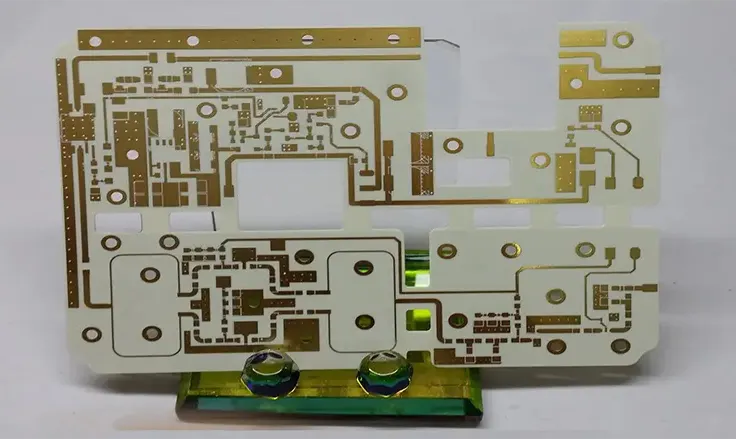

What Is a Ceramic PCB? A Ceramic PCB is a high-performance printed circuit board manufactured using ceramic substrate materials such as Alumina (Al₂O₃), Aluminum Nitride (AlN), or Beryllium Oxide (BeO). Unlike traditional FR-4 PCBs, Ceramic PCBs provide: Excellent thermal conductivity High mechanical strength Superior electrical insulation Stable performance in extreme environments Ceramic PCB technology is...

What Is a Burn-in Board PCB? A Burn-in Board PCB is a specialized printed circuit board used in semiconductor reliability testing to identify early device failures. It connects packaged integrated circuits to burn-in test systems, allowing devices to operate under elevated temperature, voltage, and electrical stress conditions over extended periods. Burn-in board PCBs play a...

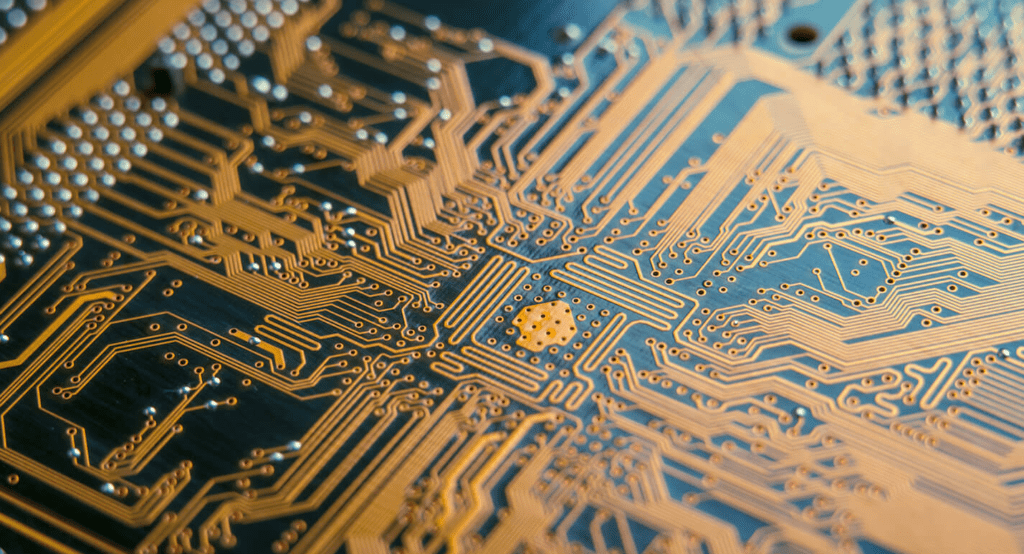

What Is a High TG PCB? A High TG PCB is a printed circuit board manufactured using materials with a high glass transition temperature (Tg). The Tg value indicates the temperature at which the PCB substrate transitions from a rigid state to a softer, rubber-like state. Compared to standard FR-4, High Tg PCBs maintain mechanical...

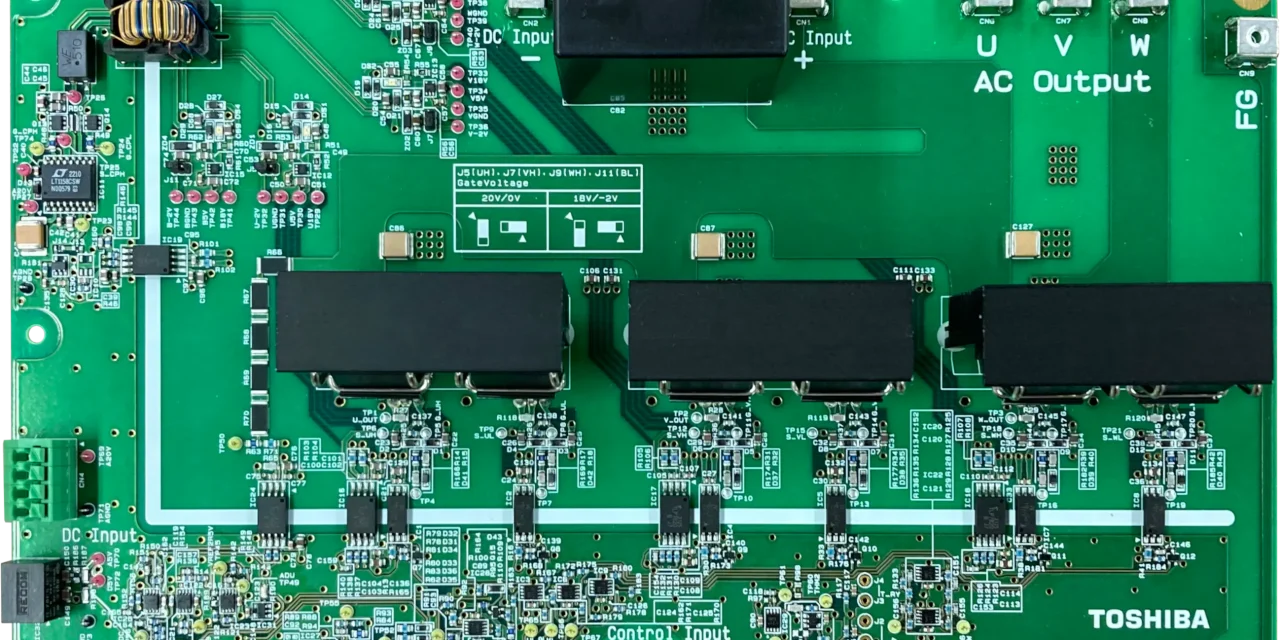

What Is a SiC PCB? A SiC PCB is a specialized printed circuit board designed for silicon carbide (SiC) power devices, such as SiC MOSFETs and SiC diodes. These PCBs are engineered to operate under high voltage, high current, and high temperature conditions commonly found in advanced power electronics. Compared with conventional PCBs, SiC PCBs...

What Is an Alumina PCB? An Alumina PCB is a type of ceramic PCB manufactured using aluminum oxide (Al₂O₃) as the base substrate. Unlike traditional FR-4 materials, Alumina PCB provides superior thermal conductivity, excellent electrical insulation, and outstanding stability under high temperature and high power conditions. Because of these characteristics, Alumina PCBs are widely used...

What Is an Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Compared with organic laminates, Alumina PCBs provide superior thermal conductivity, excellent electrical insulation, and outstanding resistance to high temperature and harsh environments. Alumina PCBs are widely used in power electronics, semiconductor packaging,...

What Is a Burn-in PCB? A Burn-in PCB is a specialized printed circuit board used for burn-in testing and stress screening, where electronic components or assemblies are operated under elevated temperature, voltage, and current conditions for extended periods. The goal of a Burn-in PCB is to identify early-life failures and improve long-term product reliability. Burn-in...

A Burn-in PCB is a specialized test interface designed for accelerated semiconductor reliability screening under sustained electrical and thermal stress. In burn-in systems, the PCB is exposed to continuous high temperature, elevated voltage, and long operating cycles, making it one of the most mechanically and electrically stressed PCB types in semiconductor test environments. Unlike functional...

High TG materials play a decisive role in modern PCB designs where elevated operating temperatures, complex multilayer stackups, and long-term reliability are mandatory. As electronic systems continue to push higher power density and tighter integration, conventional low-TG laminates increasingly become a limiting factor in both manufacturing yield and field performance. Understanding the Importance of TG...