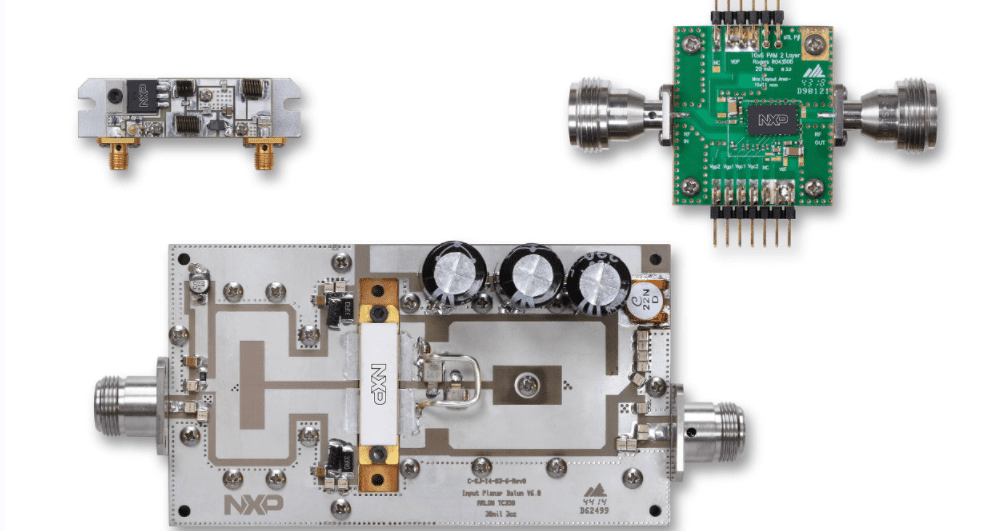

With the rapid advancement of high-frequency electronics, modern RF and microwave systems demand PCBs with ultra-low loss, stable dielectric properties, and controlled impedance performance. Applications such as 5G wireless communication, satellite systems, radar, high-frequency RF front-end modules, and microwave circuits require materials that maintain signal integrity at GHz frequencies. Duroid PCB is a PTFE-based high-frequency...

HomeTag

high-reliability PCB - KKPCB

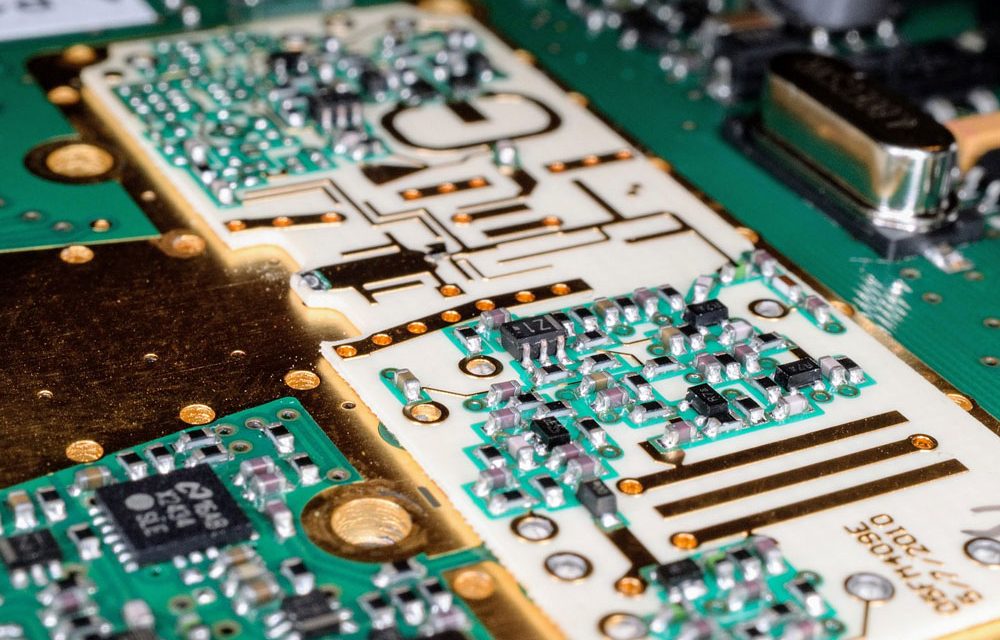

High-frequency electronics are rapidly expanding across modern industries. From 5G communication infrastructure and WiFi systems to radar sensing, satellite communication, and advanced RF front-end modules, more products are operating in the GHz range than ever before. In these designs, the PCB is not just a carrier for components—it becomes a critical part of the signal...

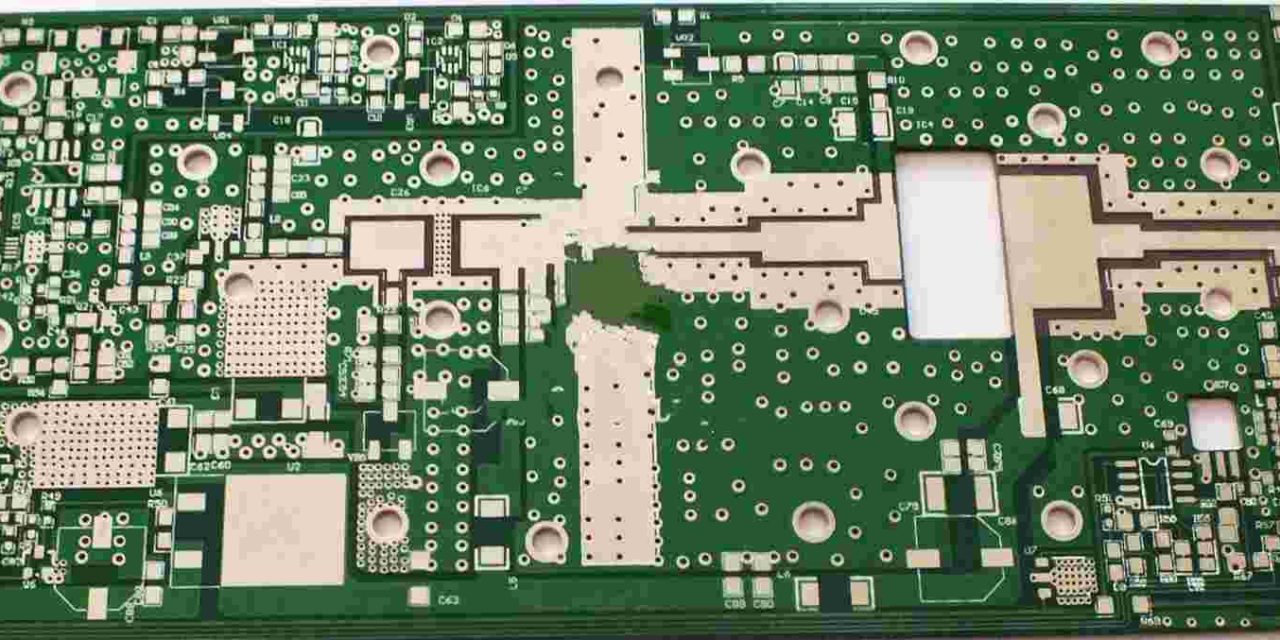

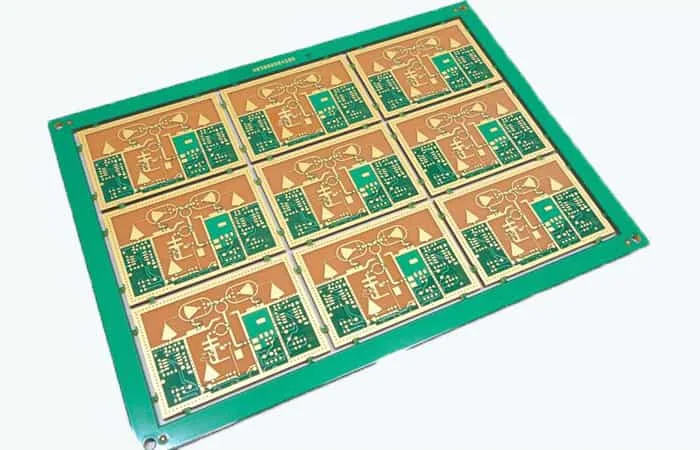

A Rogers PCB is a high-performance printed circuit board manufactured using Rogers high-frequency laminate materials, which outperform standard FR-4 in RF, microwave, and high-frequency signal applications. Rogers PCB materials provide low dielectric loss, stable dielectric constant (Dk), and excellent controlled impedance, making them essential for modern high-speed electronics and wireless communication systems. As technology evolves,...

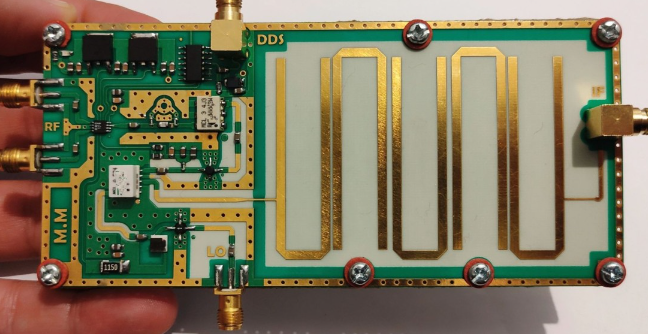

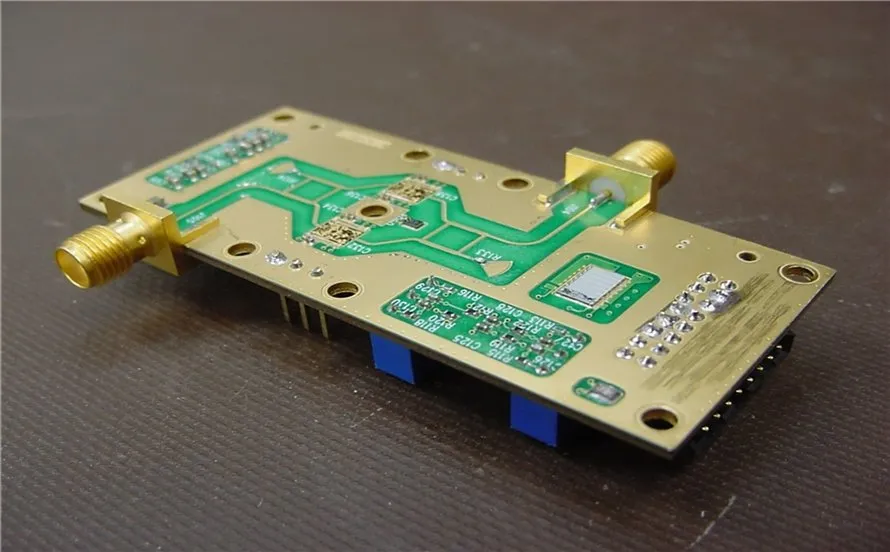

An RF Trace PCB is a specialized printed circuit board designed for RF signal transmission and high-frequency applications, where signal loss, impedance stability, and EMI control are critical. As wireless technologies such as 5G, WiFi, GPS, IoT, and radar systems continue to grow, RF PCB performance requirements become stricter than ever. Unlike ordinary digital traces,...

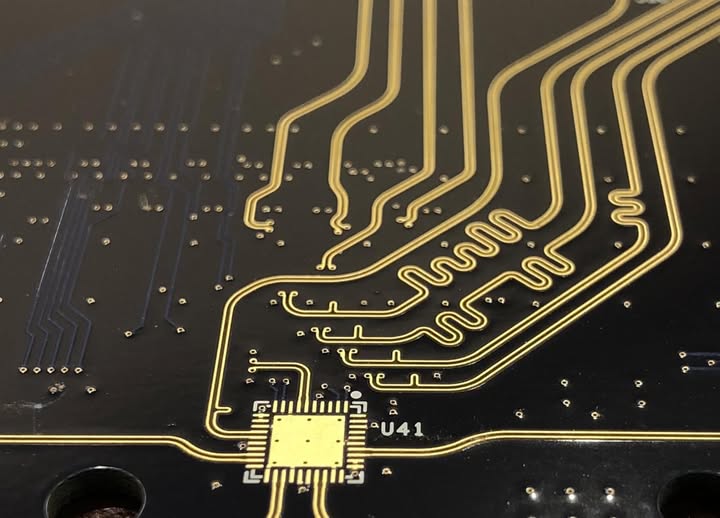

A Differential Pair PCB is a printed circuit board designed to route signals in pairs of two complementary traces, where one carries the positive signal and the other carries the negative signal. Instead of relying on a single-ended reference to ground, differential signaling transmits information through the voltage difference between the two traces, making it...

What Is a Rogers PCB? A Rogers PCB is a high-frequency printed circuit board manufactured using Rogers laminate materials, which are engineered for RF, microwave, and high-speed signal applications. Compared with standard FR-4, Rogers materials offer lower dielectric loss, more stable dielectric constant (Dk), and better electrical performance at high frequencies. Because of these advantages,...

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to transmit high-frequency electrical signals—typically in the MHz to GHz range—while maintaining signal integrity, minimizing loss, and reducing EMI. These PCBs are critical in applications such as RF communication, microwave devices, 5G modules, radar systems, high-speed networking,...

What Is an RF Trace PCB? An RF Trace PCB is a printed circuit board designed with optimized RF trace routing to carry radio frequency (RF) signals with minimal loss, stable impedance, and strong EMI control. RF traces are transmission lines that must maintain consistent electrical performance at high frequencies, typically from hundreds of MHz...

Differential Pair PCB: Controlled Impedance Routing for High-Speed and Low-Noise Signal Transmission

What Is a Differential Pair PCB? A Differential Pair PCB is a printed circuit board designed with differential signal pairs to transmit high-speed data with improved noise immunity and stable signal quality. A differential pair consists of two matched traces carrying equal and opposite signals, allowing the receiver to detect the voltage difference between them....

What Is a Fine Line PCB? A Fine Line PCB is a high-precision printed circuit board manufactured with ultra-thin trace width and tight trace spacing, enabling high-density routing for advanced electronic products. Compared with standard PCB technology, Fine Line PCB fabrication focuses on achieving smaller line/space (L/S), higher wiring density, and improved signal performance in...