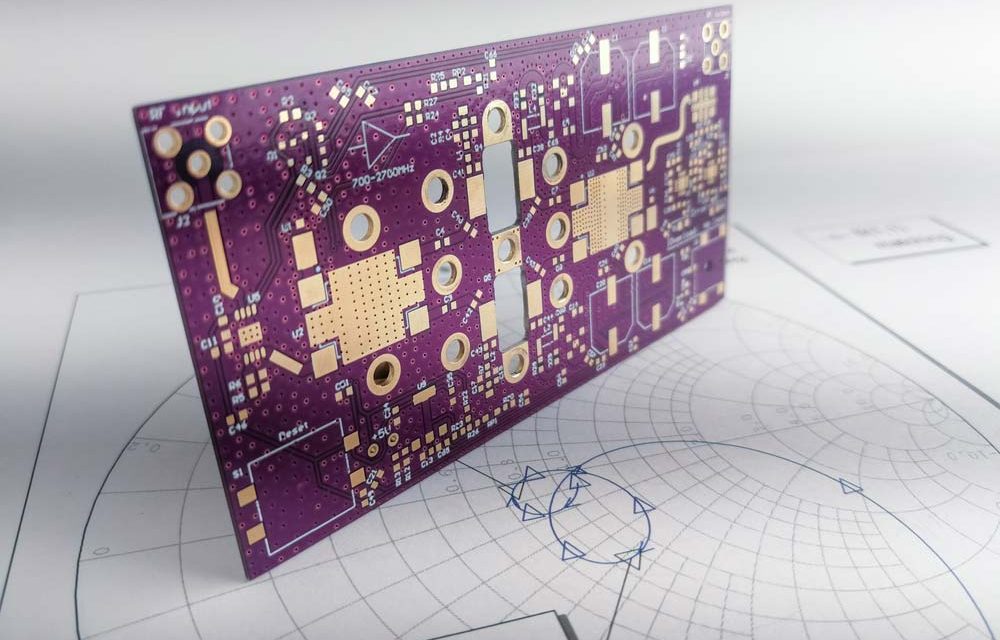

What Is a Rogers PCB? A Rogers PCB is a printed circuit board that uses Rogers high-frequency laminates, such as RO4003C, RO4350B, and Duroid series, designed for low dielectric loss, precise impedance control, and high-frequency signal transmission. Rogers PCBs are essential in 5G communications, RF/microwave modules, high-speed computing, and aerospace electronics. Why Rogers PCB Technology...

HomeTag

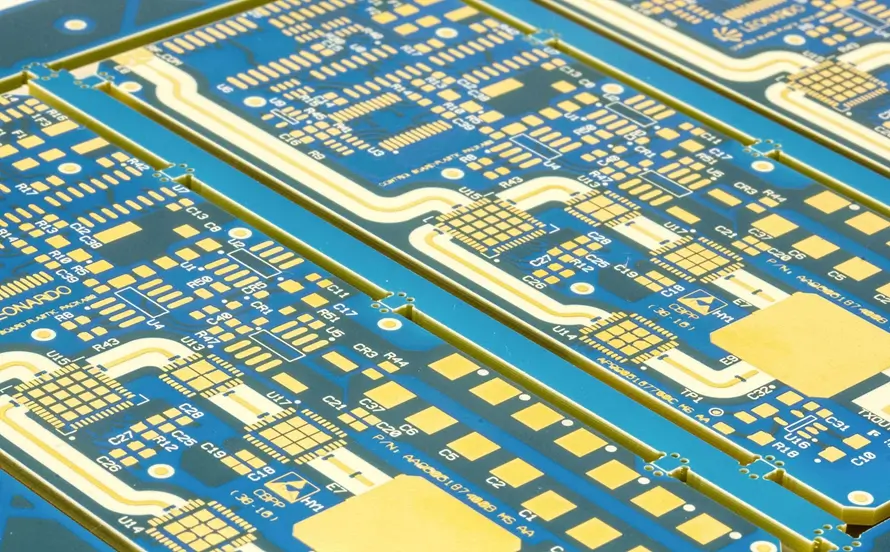

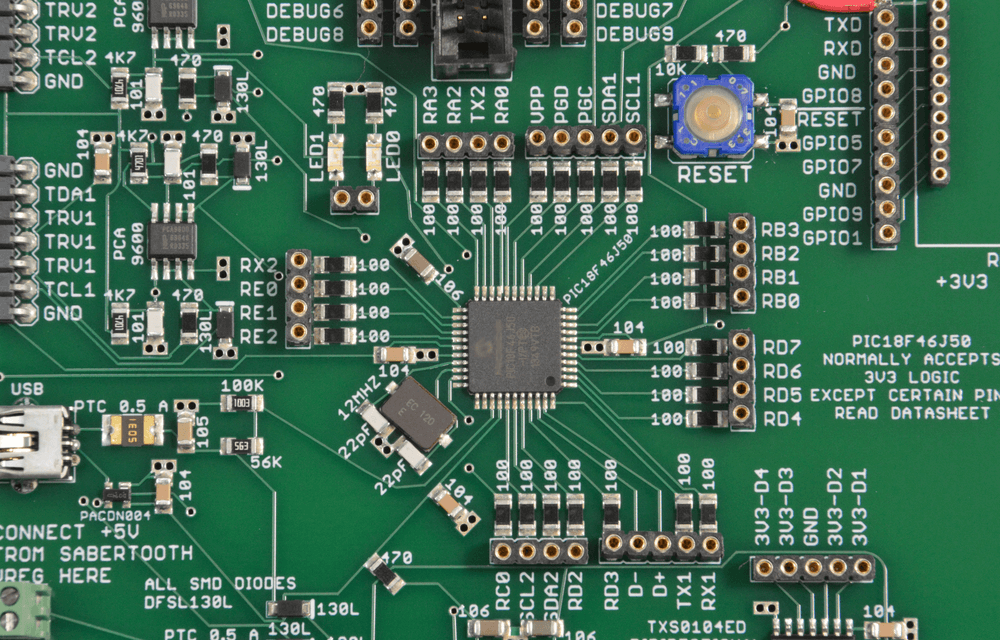

Controlled Impedance PCB - KKPCB

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to carry high-speed and high-frequency signals with minimal loss, reflection, or distortion. These PCBs are crucial in RF, microwave, 5G, high-speed computing, and semiconductor test applications, where signal integrity and low insertion loss are essential for system...

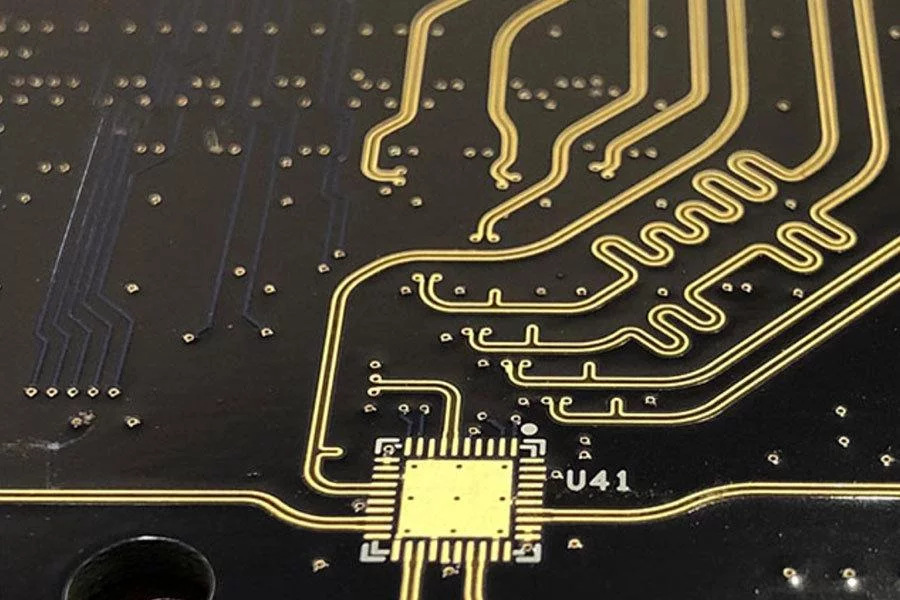

What Is an RF Trace PCB? An RF Trace PCB is a printed circuit board designed to route high-frequency RF signals with minimal signal loss, reflection, and distortion. These PCBs are optimized for controlled impedance, low insertion loss, and high signal integrity, making them essential for applications such as 5G modules, mmWave systems, wireless communication,...

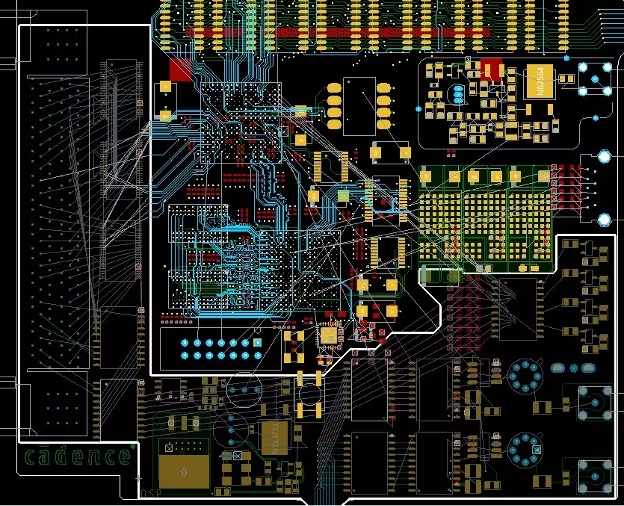

What Is a Differential Pair PCB? A Differential Pair PCB is a printed circuit board designed to route differential signal pairs, which are two complementary signals transmitted simultaneously to improve noise immunity, reduce crosstalk, and maintain signal integrity. Differential pair technology is critical in high-speed digital interfaces, such as USB, HDMI, PCIe, Ethernet, DDR memory,...

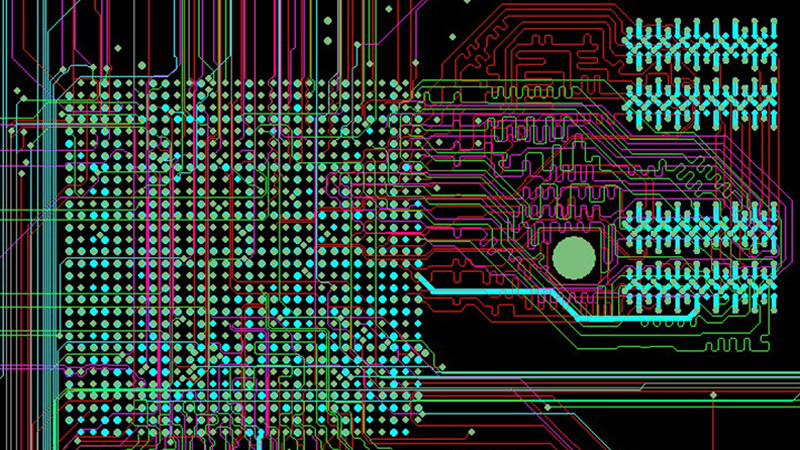

What Is a Fine Line PCB? A Fine Line PCB is a printed circuit board that uses extremely narrow traces and spaces to support high-density, complex electronic designs. Fine line technology is essential for applications where board real estate is limited but high-speed performance and signal integrity are required, such as smartphones, 5G modules, high-speed...

What Is a High Speed Logic PCB? A High Speed Logic PCB is a printed circuit board designed to support high-speed digital logic circuits, where signal rise times are extremely fast and timing accuracy is critical. These PCBs ensure minimal signal distortion, precise timing, and reliable data transmission for high-performance computing, telecommunication, and semiconductor testing...

What Is a Signal Integrity PCB? A Signal Integrity (SI) PCB is a printed circuit board designed to maintain clean, stable high-speed signal transmission across digital, analog, or mixed-signal circuits. SI PCBs are essential for applications where data integrity, minimal signal distortion, and timing accuracy are critical, such as 5G communications, high-speed computing, automotive electronics,...

What Is a Microvia PCB? A Microvia PCB is a printed circuit board that uses microvias, which are very small drilled holes (typically <150 μm) to interconnect layers in high-density, multilayer HDI PCBs. Microvias enable fine-pitch routing, high pin count IC integration, and compact board layouts, making them essential for advanced electronics such as smartphones,...

What Is a High Reliability PCB? A High Reliability PCB is a printed circuit board designed and manufactured to perform consistently under extreme environmental, electrical, and mechanical conditions. These PCBs are engineered for long service life, stable electrical performance, and minimal failure risk. High reliability PCBs are essential for applications where system failure is not...

What Is a Low Loss PCB? A Low Loss PCB is a printed circuit board designed with low dielectric loss materials to minimize signal attenuation during high-frequency and high-speed signal transmission. These PCBs are critical for applications where signal integrity, phase stability, and low insertion loss are essential. Low loss PCBs are widely used in...