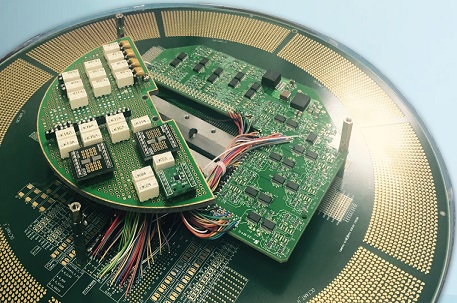

In automated test equipment development, early-stage validation determines long-term system reliability. The ATE PCB Prototype provides a controlled platform for verifying electrical performance, mechanical interfaces, and test repeatability before production deployment. A well-designed ATE PCB prototype reduces risk and accelerates development cycles. Role of ATE PCB Prototypes in Test Engineering An ATE PCB Prototype bridges...

HomeTag

Automated Test Equipment PCB - KKPCB

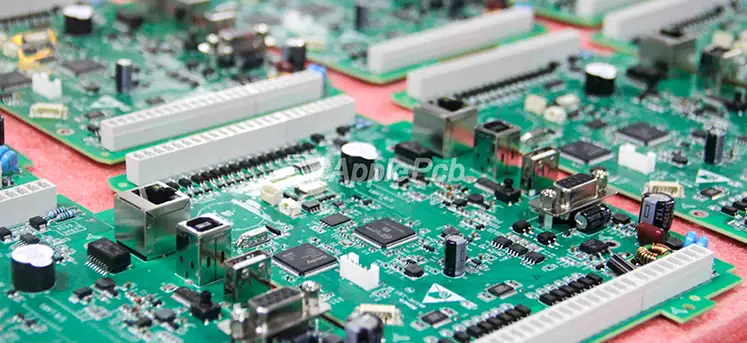

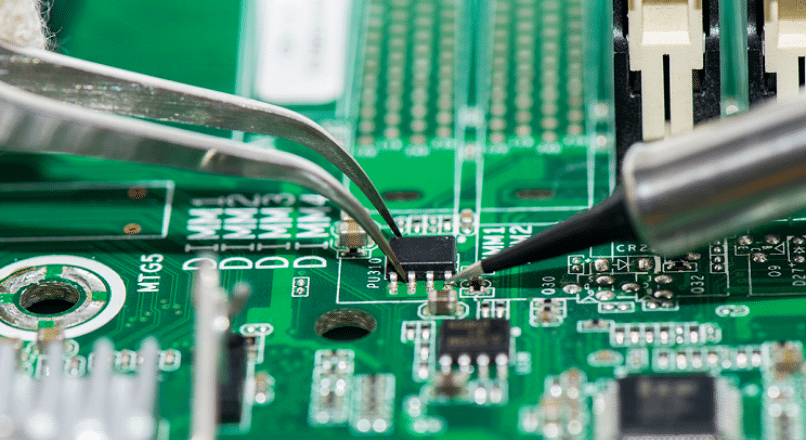

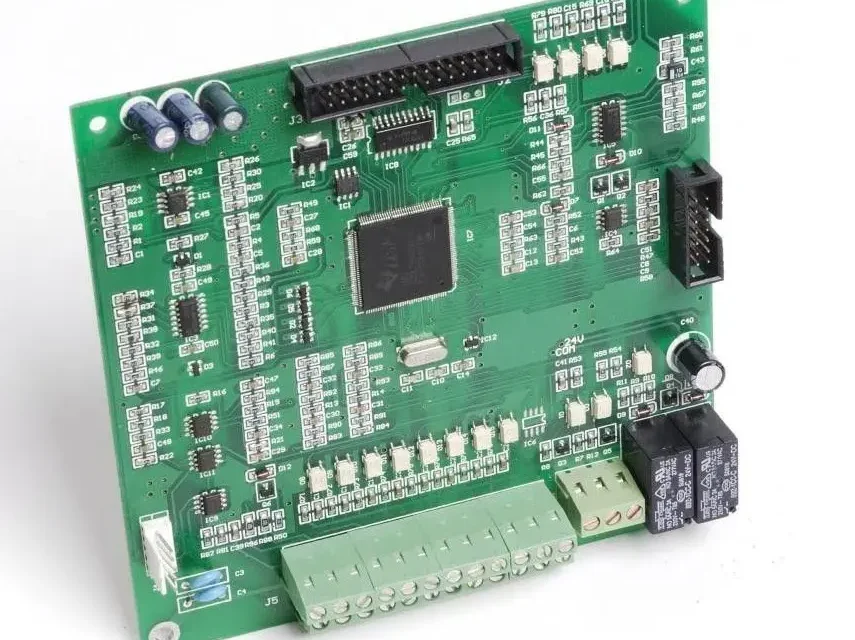

Automated test equipment relies not only on PCB design and fabrication, but also on precise and repeatable assembly. ATE PCB Assembly plays a critical role in ensuring signal integrity, power stability, and mechanical reliability throughout semiconductor testing operations. High-quality assembly directly impacts test accuracy and system uptime. What Is ATE PCB Assembly? ATE PCB Assembly...

Between initial prototyping and full-scale production, test engineers often require a controlled, repeatable manufacturing stage. Small batch ATE PCB production fills this gap by providing consistent quality, stable electrical performance, and scalable processes for automated test equipment (ATE) development. Small batch manufacturing enables engineering teams to validate real production conditions without the risks of mass...

Before an automated test system enters production, its electrical and mechanical behavior must be thoroughly validated. The ATE PCB Prototype serves as the critical platform for early-stage verification, allowing engineers to evaluate signal integrity, power delivery, and interface compatibility under real test conditions. A well-executed ATE PCB prototype reduces development risk and accelerates time to...

In automated semiconductor testing, the performance of a test system is not determined by PCB fabrication alone. ATE PCB Assembly plays a decisive role in ensuring electrical accuracy, mechanical stability, and long-term repeatability throughout the entire test lifecycle. A production-ready ATE PCB assembly process directly supports higher yield, fewer false failures, and stable high-volume testing....

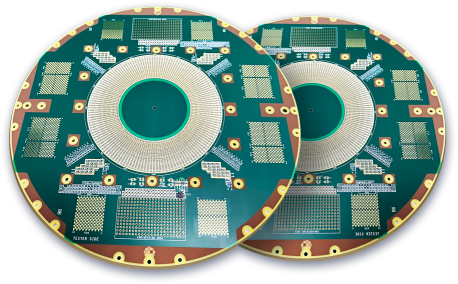

In automated semiconductor testing, accuracy must be maintained not just once—but across thousands of test cycles. A Custom ATE PCB is designed specifically to match the electrical, mechanical, and environmental requirements of each test platform, ensuring stable and repeatable test results over time. A professionally engineered custom ATE PCB reduces false failures, improves yield, and...

Automated Test Equipment (ATE) systems require test boards that deliver precise electrical performance and long-term reliability. A Custom ATE PCB is engineered specifically to match the electrical, mechanical, and functional requirements of each test platform, ensuring accurate and repeatable test results. A well-designed custom ATE PCB plays a critical role in advanced semiconductor and electronic...

Automated Test Equipment (ATE) plays a critical role in semiconductor and electronic product validation. At the core of every ATE system is the Custom ATE PCB, a highly specialized test board designed to interface precisely with the device under test and the test platform. Unlike standard PCBs, custom ATE PCBs are engineered for accuracy, durability,...

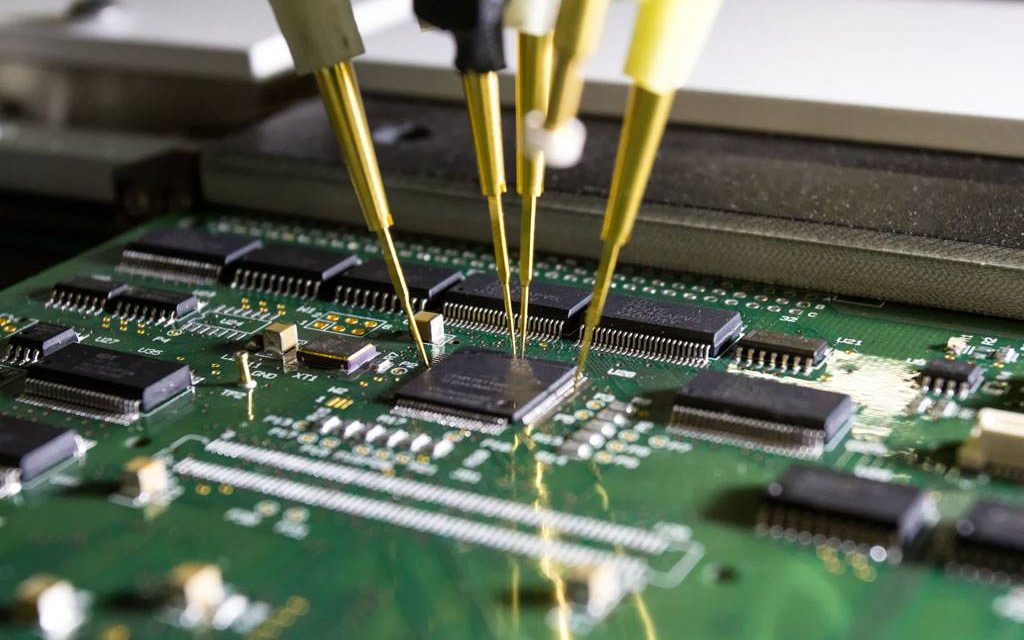

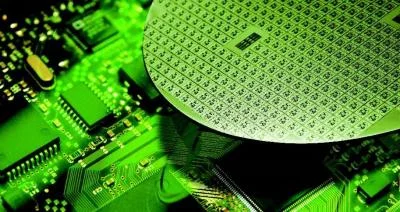

Automated Test Equipment (ATE) is the backbone of modern semiconductor validation and mass production. At the center of every ATE system is the ATE Test PCB, which directly affects test accuracy, yield stability, and long-term reliability. A well-engineered ATE test PCB ensures that measured performance reflects the device under test—not limitations of the test hardware....

Automated Test Equipment (ATE) platforms are highly configurable, but their performance ultimately depends on how well the test interface matches the device under test. A Custom ATE PCB is specifically designed to bridge this gap by aligning electrical, mechanical, and system-level requirements for accurate and repeatable semiconductor testing. Unlike off-the-shelf boards, a custom ATE PCB...